Compostable environmentally friendly PLA blister white sheet

PLA Biodegradability: Made of starch raw materials extracted from renewable plant resources such as corn and cassava, it can be completely degraded by microorganisms in nature under specific conditions after use, and finally produces carbon dioxide and water, without polluting the environment.

- top leader plastic

- China

- 10-15 working days

- 180 tons/month

- Information

Compostable environmentally friendly PLA blister white sheet Can be used to produce room temperature cold drink cups, cup lids, etc.

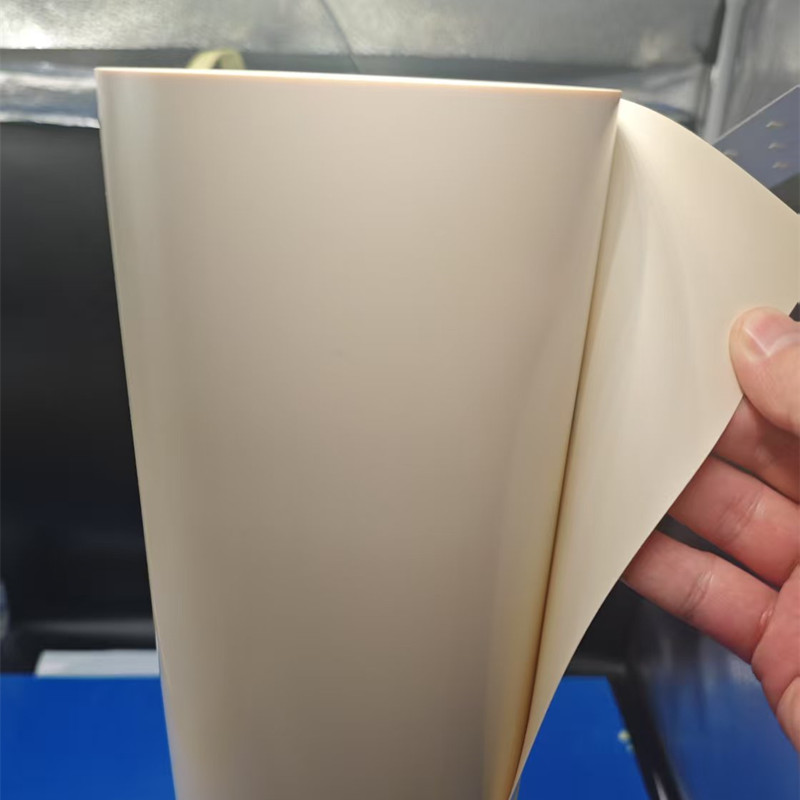

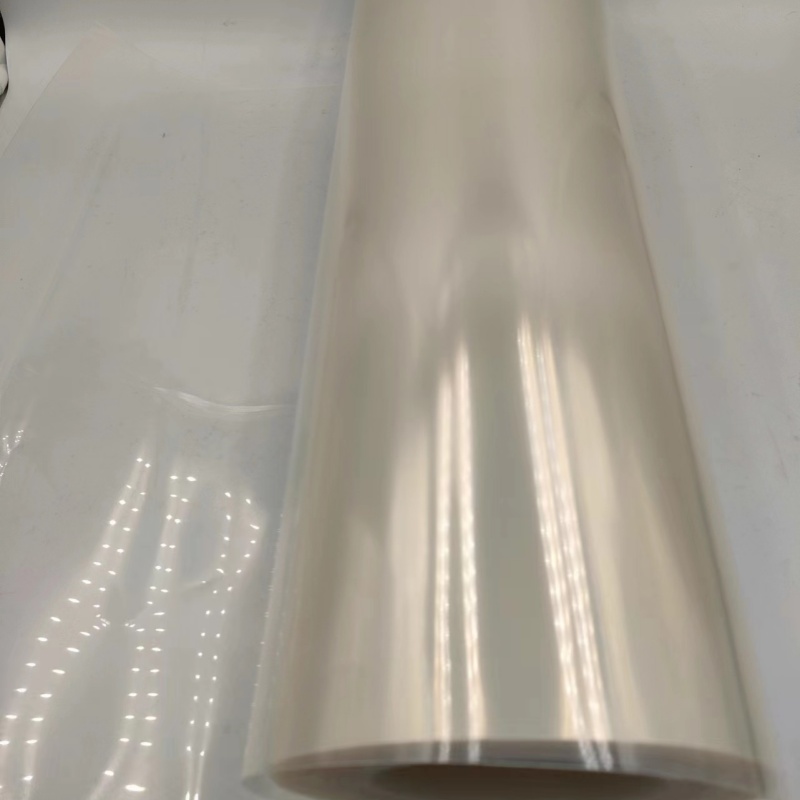

Degradable white polylactic acid coil

Compostable environmentally friendly PLA blister white sheet

Can be used to produce room temperature cold drink cups, cup lids, etc

Biodegradability: Made of starch raw materials extracted from renewable plant resources such as corn and cassava, it can be completely degraded by microorganisms in nature under specific conditions after use, and finally produces carbon dioxide and water, without polluting the environment.

Good mechanical properties: It has certain strength and rigidity, which can meet the strength requirements of products such as room temperature cold drink cups and cup lids during production, transportation and use. It also has certain toughness and is not easy to break.

Good processing performance: It can be made into products of various shapes and sizes through various processing methods such as extrusion and blistering, and is suitable for ordinary sheet extrusion equipment and blistering equipment.

High safety: It is safe, non-toxic, odorless, meets food contact standards, and can be directly used to package food and beverages.

Production process

Degradable white polylactic acid coil: Generally, the polylactic acid resin particles are heated and melted by an extruder, and then extruded into sheets through a mold, and then traction, cooling and other processes are carried out, and finally wound into coils.

Compostable and environmentally friendly PLA blister white sheet: First, the polylactic acid raw material is made into a sheet, and then according to the product design requirements, the sheet is heated and softened through the blister molding process, and then it is adsorbed on the mold surface by vacuum suction, and the desired blister product shape is formed after cooling.

Application field

Catering industry: It can be used to make room temperature cold drink cups, cup lids, disposable lunch boxes, salad bowls, sushi boxes, etc. It has high transparency, can show the effect of food, and is oil-resistant and water-resistant, suitable for a variety of foods.

Packaging industry: It is used to produce various blister packaging products, such as fruit packaging boxes, egg trays, cushioning packaging pads, etc., which play a role in protecting and displaying products.

Market prospects

With the global emphasis on environmental protection and the implementation of policies such as "plastic restriction order" and "plastic ban order", the use of traditional plastic packaging materials is restricted, and the market demand for degradable polylactic acid materials is increasing. Degradable white polylactic acid coils and compostable environmentally friendly PLA blister white sheets are ideal materials to replace traditional plastics, and the market prospects are broad.

What's your delivery time?

Within 15-20 days after received payment...more

Within 15-20 days after received payment...more

Get the latest price? We'll respond as soon as possible(within 12 hours)