transparent and biodegradable PLA film Thermoforming roll

Introduction to degradable polylactic acid, compostable PLA, environmental protection, polylactic acid transparent sheets and thermoforming coils:

Degradable polylactic acid and compostable PLA

Basic concept: Polylactic acid (PLA) is a polyester polymer obtained by polymerization with lactic acid as the main raw material, and is a new type of biodegradable material.

- t

- China

- 10-15 working days

- 180 tons/month

- Information

Polylactic acid transparent sheet

Ultra-transparent and biodegradable PLA film

Compostable PLA sheet

Environmentally friendly PLA transparent sheet

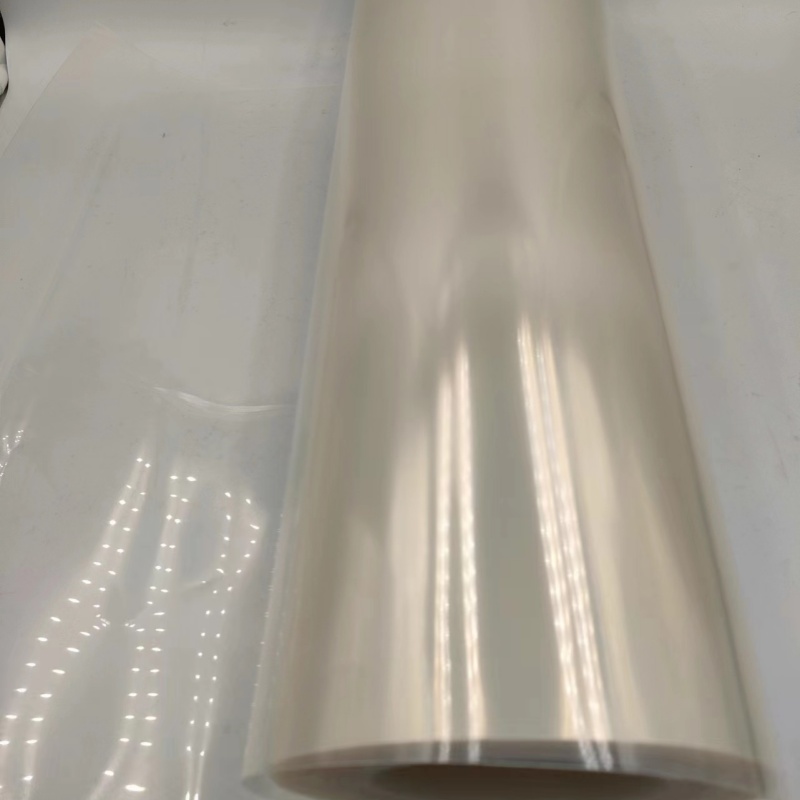

Thermoforming roll

High transparency: It has high transparency comparable to PET materials, can clearly display the contents of the package, and is suitable for packaging fields with high transparency requirements, such as transparent fruit boxes, fresh trays, transparent milk tea cups, lunch box lids, cake box lids and other products.

Degradability: Made of 100% polylactic acid, it is a fully degradable material. It can be gradually decomposed in the natural environment after being discarded, and will not cause long-term environmental pollution like traditional plastic sheets.

Good processing performance: It can adopt a variety of molding processes such as cold mold negative pressure molding process and cup positive pressure molding process, and pure polylactic acid ordinary blister machine can be produced, which is suitable for all blister factories.

Application field: It is mainly used in the packaging industry, such as food packaging, daily necessities packaging, etc., which can meet the requirements of product display and environmental protection. It can also be used in some transparent decorative materials, stationery and other fields.

Polylactic acid thermoforming coil

Characteristics

Good thermoforming: Polylactic acid has excellent thermoforming properties. Thermoforming coils can be made by extrusion molding and other processes. It can be easily thermoformed and processed into various plastic products such as cups, boxes, trays, etc. by blister molding, blow molding, etc.

Dimensional stability: It has good dimensional stability during the thermoforming process and the use process after molding, and can maintain the shape and dimensional accuracy of the product to meet the design and use requirements of different products.

Customizability: It can be customized according to customer needs, including the width, thickness, color, etc. of the coil to adapt to different application scenarios and product requirements.

Within 15-20 days after received payment...more