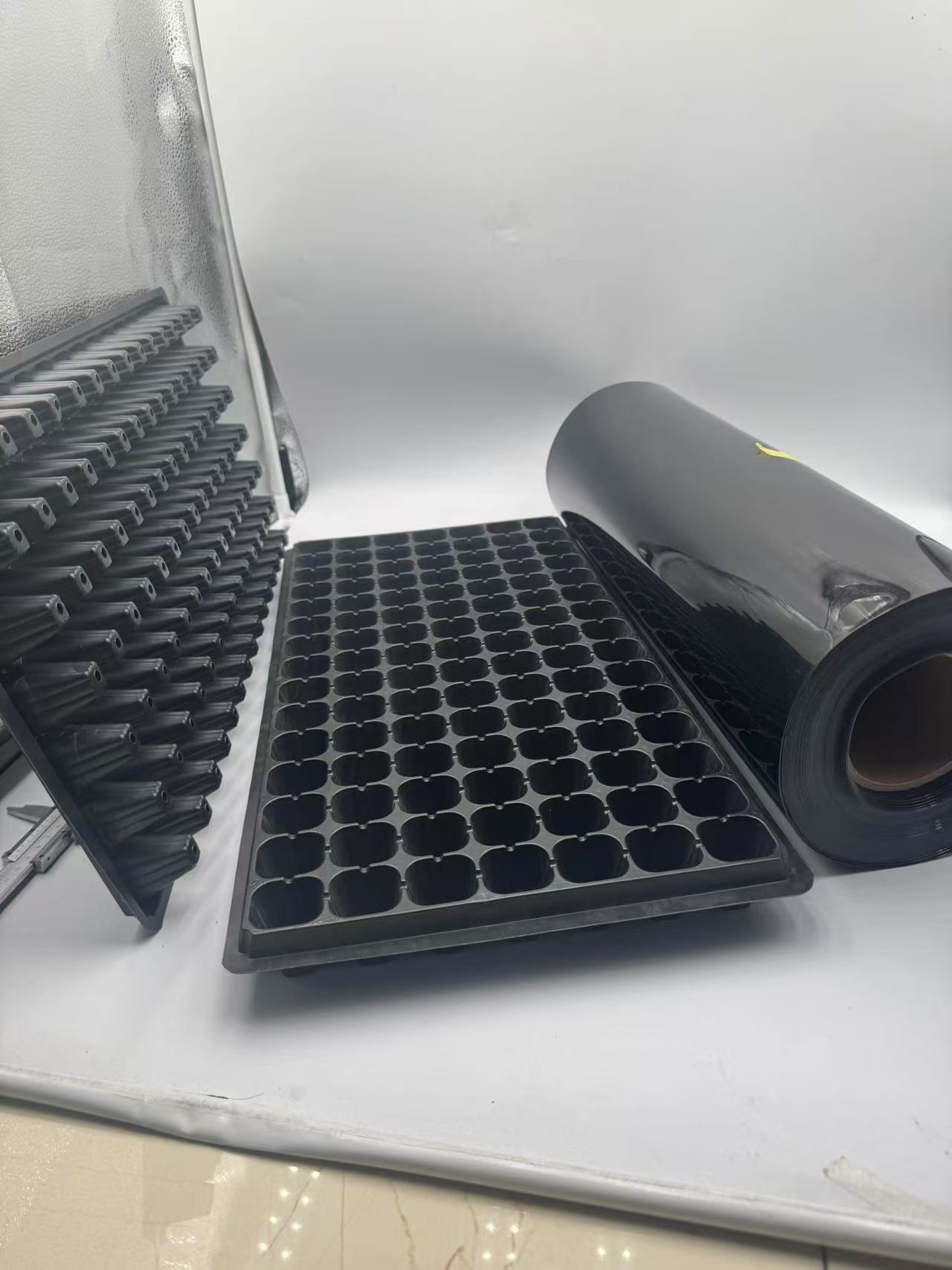

527PS The Versatile Application of PS Film in Food Blister Packaging and Seedling Trays

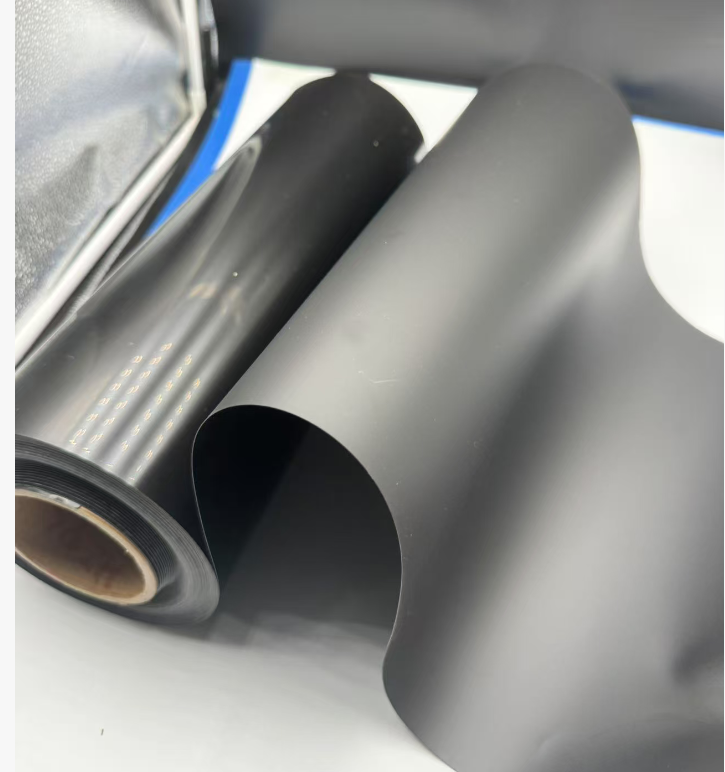

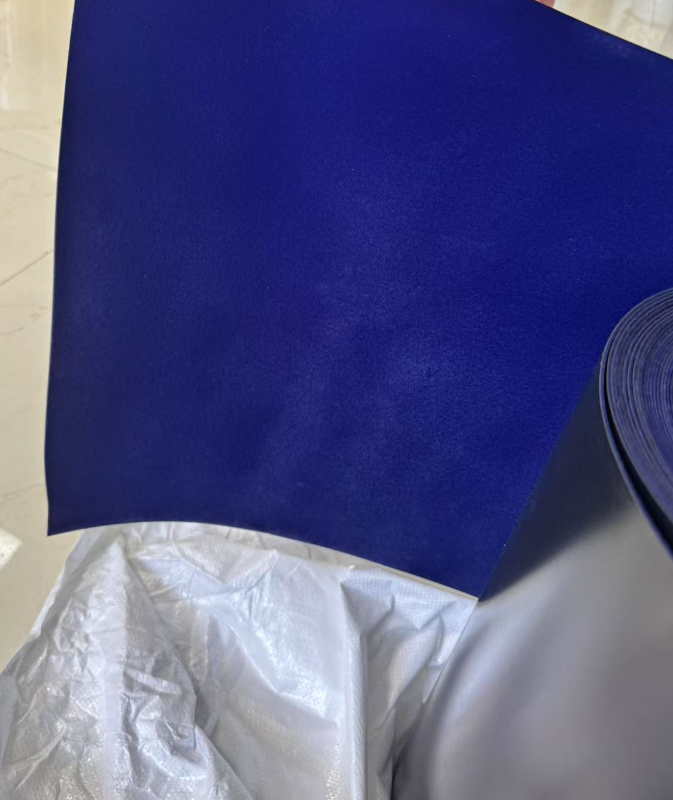

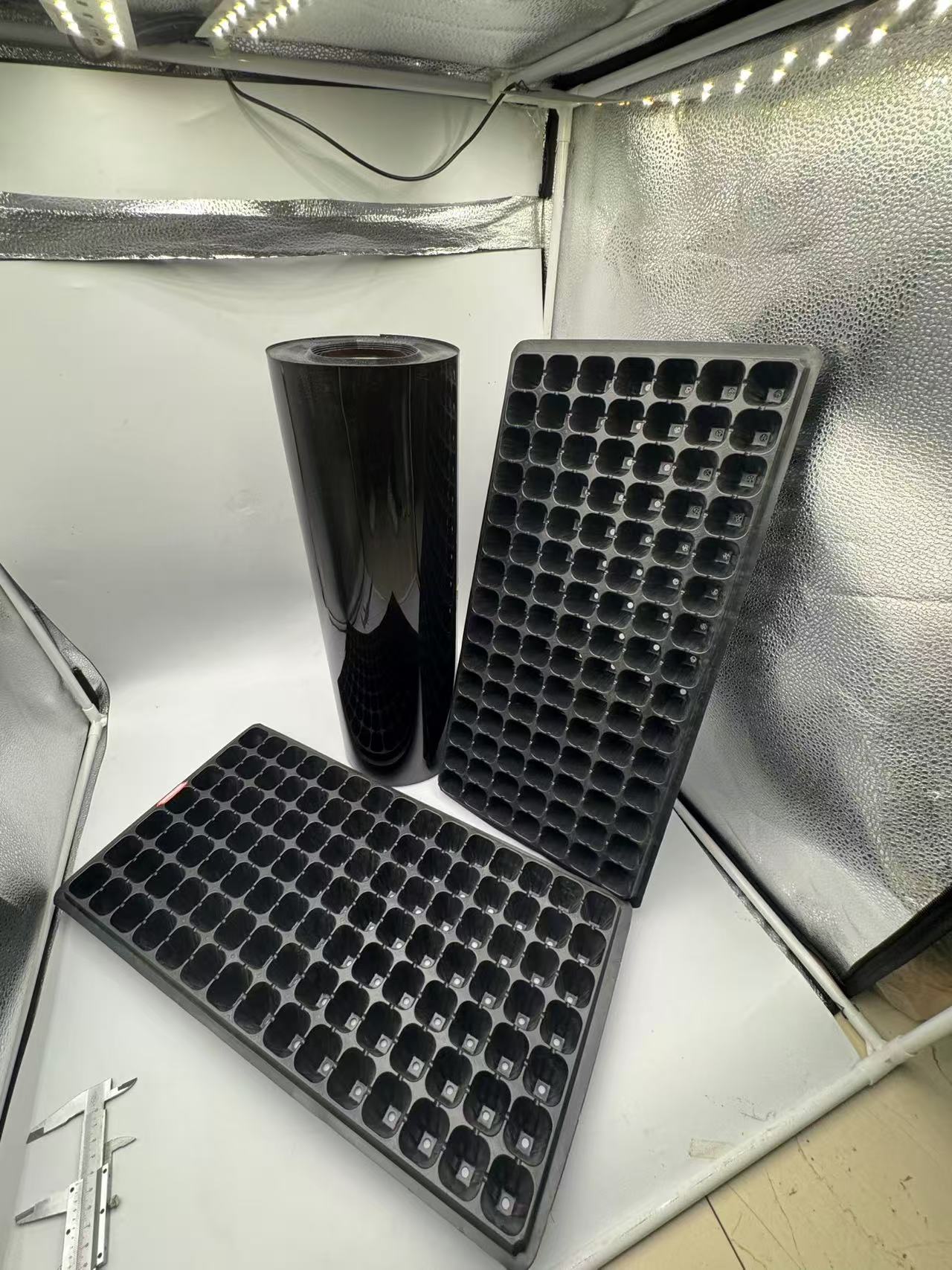

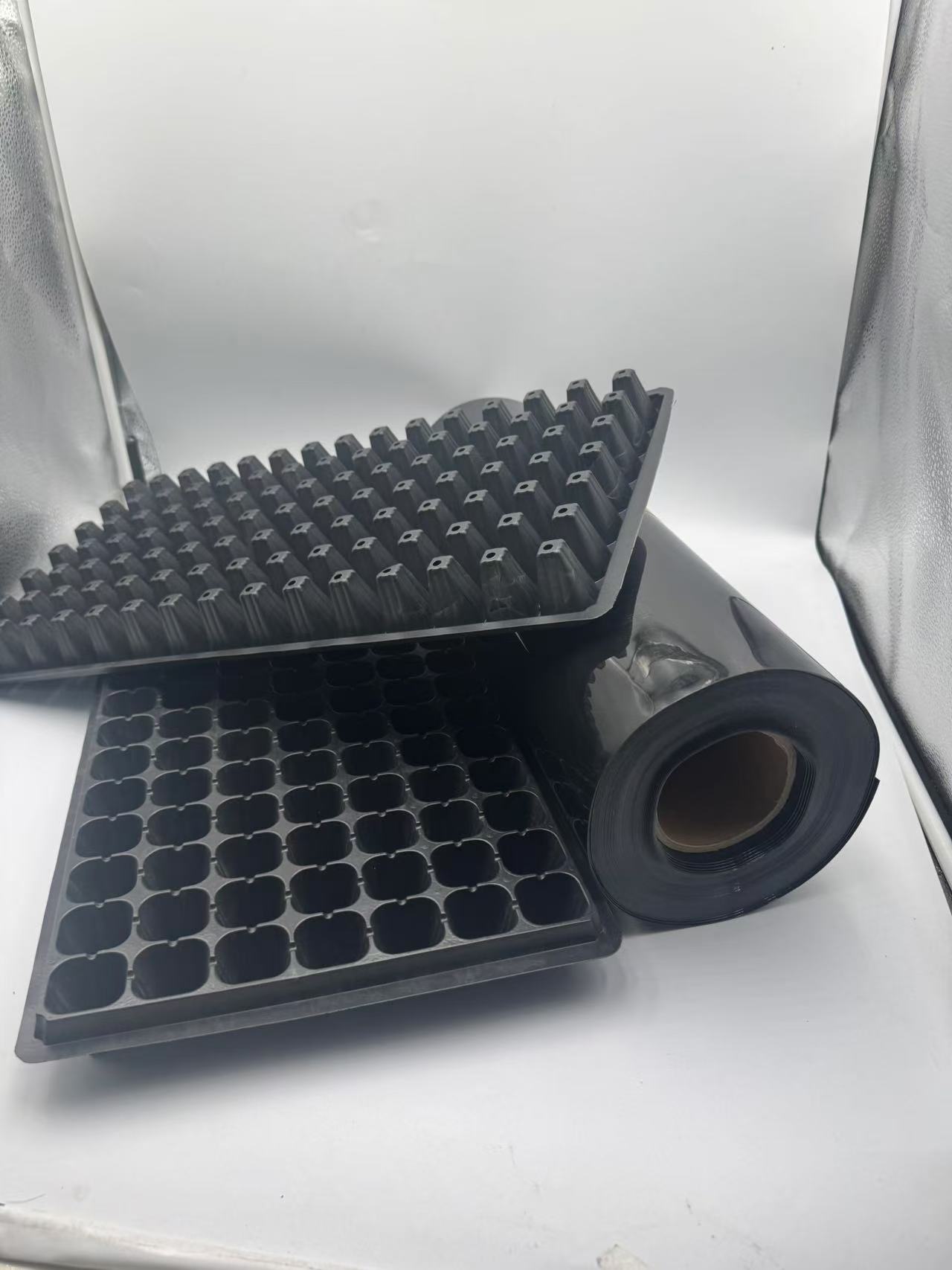

Material: PS film Thermal formed planting trays

Thickness 0.20mm/customization

Size: 300mm/Customization

GRADE: TOP grade film

color: black/white/ transparent customization

location: china

usage :film for planting tray for food trays ,for helmet,toys,controling board , switches face masks

- TOPLEADER

- china

- 15WORKING DAYS

- 5000T/M

- Information

- Video

- Download

The Versatile Application of PS Film in Food Blister Packaging and Seedling Trays

Abstract: PS film has emerged as an important material in the packaging industry, especially in food blister packaging and seedling trays. This article comprehensively explores the diverse properties of PS film that make it highly suitable for these applications. It delves into the manufacturing processes,

quality control measures, and regulatory compliance associated with PS film usage. It also focuses on the environmental impact and possible solutions for sustainable use. A close examination reveals that PS film enhances the efficiency, safety, and quality of food packaging and seedling cultivation, besides opportunities for innovation and improvement.

Keywords: PS film; Food blister packaging; Seedling trays; Packaging properties; Manufacturing processes; Sustainability

1. Introduction

In the modern world, packaging materials play a vital role in protecting and preserving various products. PS film, with its unique characteristics, has found extensive use in both food blister packaging and seedling trays. The food industry demands packaging that not only keeps food fresh and safe but also presents it attractively to consumers. In the horticulture industry, for instance, seedlings require an environment in the seedling trays that provides an ideal temperature for development. PS film has continually provided a sure way to all these variant requirements.

2. Properties of PS Film

2. Properties of PS Film

2.1 Physical Properties

The clarity of PS film is very great, and transparency is good;. The great clarity allows consumers to view clearly the food product packaged in this pack format with improved presentation of goods to choice or selection by the end consumers. In fresh fruits and vegetable or bakery products, where freshness is everything, a PS film's clear package will allow good content to be shown through this packing form. A fair film is relatively less dense which translates to less cost with applications in high-volume packages of food. The polymer exhibits good stiffness and also gives very good dimensional stability to the packs and therefore protects the packed goods and retains its shape on handling and transportation.

2.2 Chemical Properties

PS is chemically inactive, hence it has no reaction with most foods contained in it. This nature of PS is one welcome option in food packaging since maintaining food integrity and

2.3 Thermal Properties

2.3 Thermal Properties

PS film has a relatively low melting point, which allows for its application in thermoforming processes used in food blister packaging. It can be easily heated and molded into the desired

2.4 Barrier Properties

Though PS film is not as effective as some other materials in providing a complete barrier to gases and moisture, it still offers a certain level of protection. It can help block the ingress of oxygen and moisture to some extent in food blister packaging, increasing the shelf life for some food items. Seedling trays-these film materials can help in maintaining the moisture level of soil by preventing water from escaping into the environment through it, which can be required during the growth stage of the seedlings.

3. Food Blister Packaging Applications

3.1 Blister Forming Process

PS films are normally thermoformed into blister food packages. The PS film is heated up to a temperature above its glass transition temperature at which it becomes plastic-like and then laid over a mold cavity. Vacuum or pressure is applied to the heated film, forcing it into the shape of the mold cavity.

3.2 Sealing and Packaging Integrity

3.2 Sealing and Packaging Integrity

Once the food item is placed in the blister cavity, the PS film needs to be sealed to create a hermetic package. This is usually achieved by using a heat sealing process. Application involves a heated sealing bar in contact with the film to melt a thin layer of the PS, joining it together with some type of lidding material-usually laminated film or foil. For this case, careful attention must be given to heat sealing as not to inadequately compromise its integrity by

3.3 Aesthetic and Marketing Advantages

The clarity and transparency of PS film provide great aesthetic and marketing benefits in food blister packaging. The clarity of the content of the food product attracts consumers and better communicates what they are buying. Food manufacturers can take full advantage of this by presenting their products in visually attractive blister packages that showcase quality and freshness

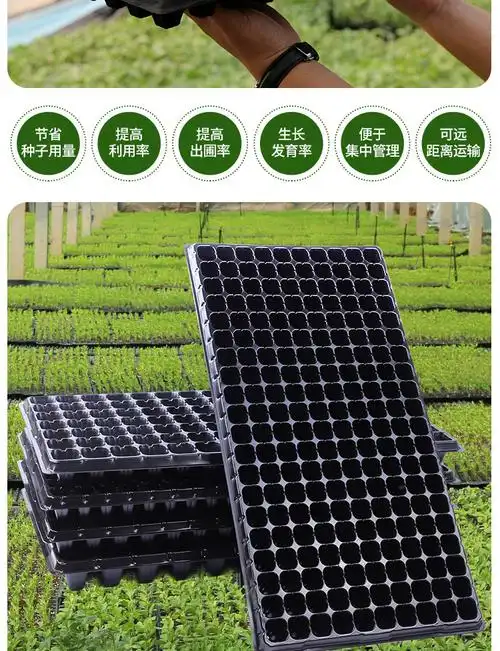

4. Application in Seedling Trays

4. Application in Seedling Trays

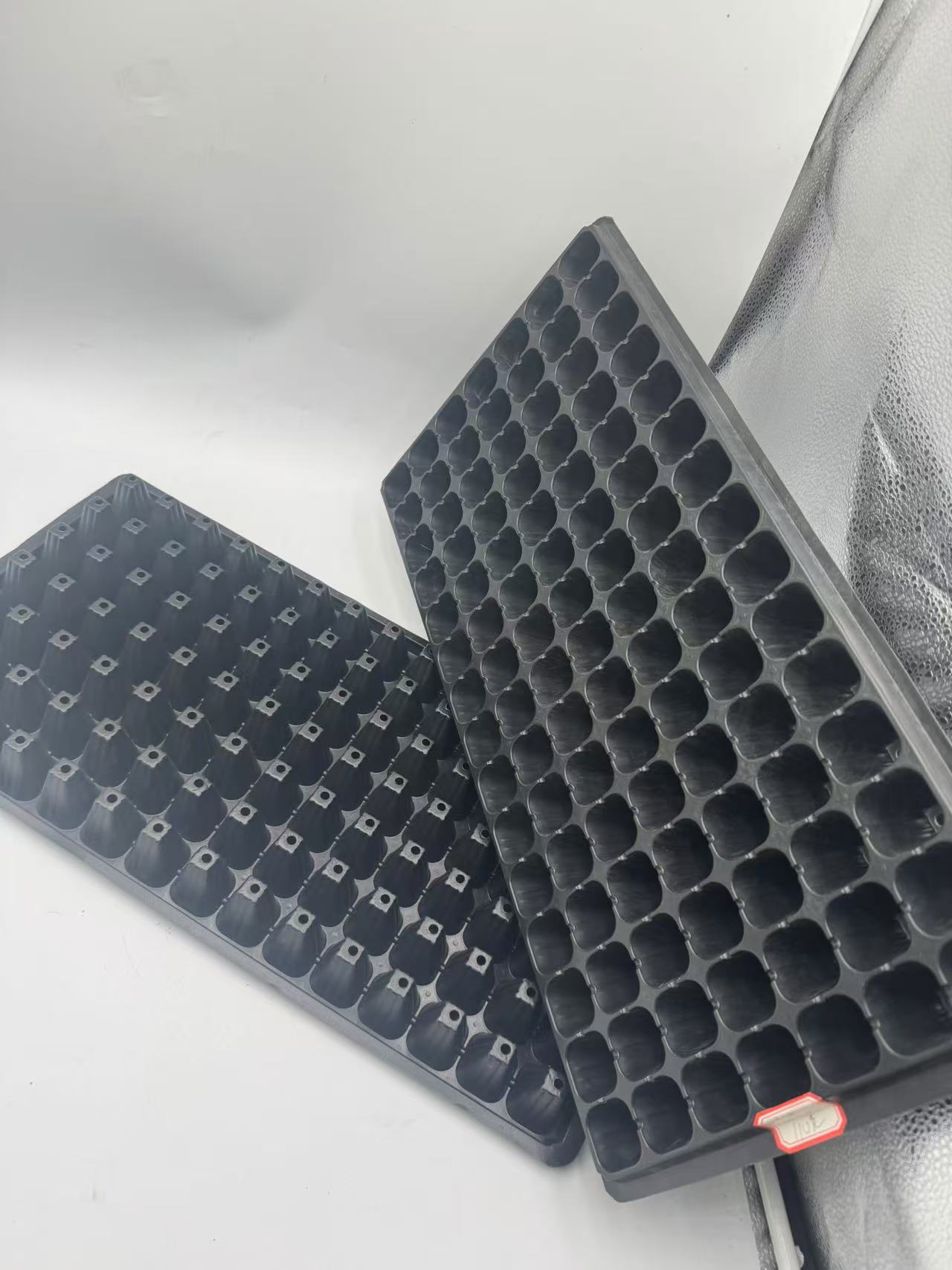

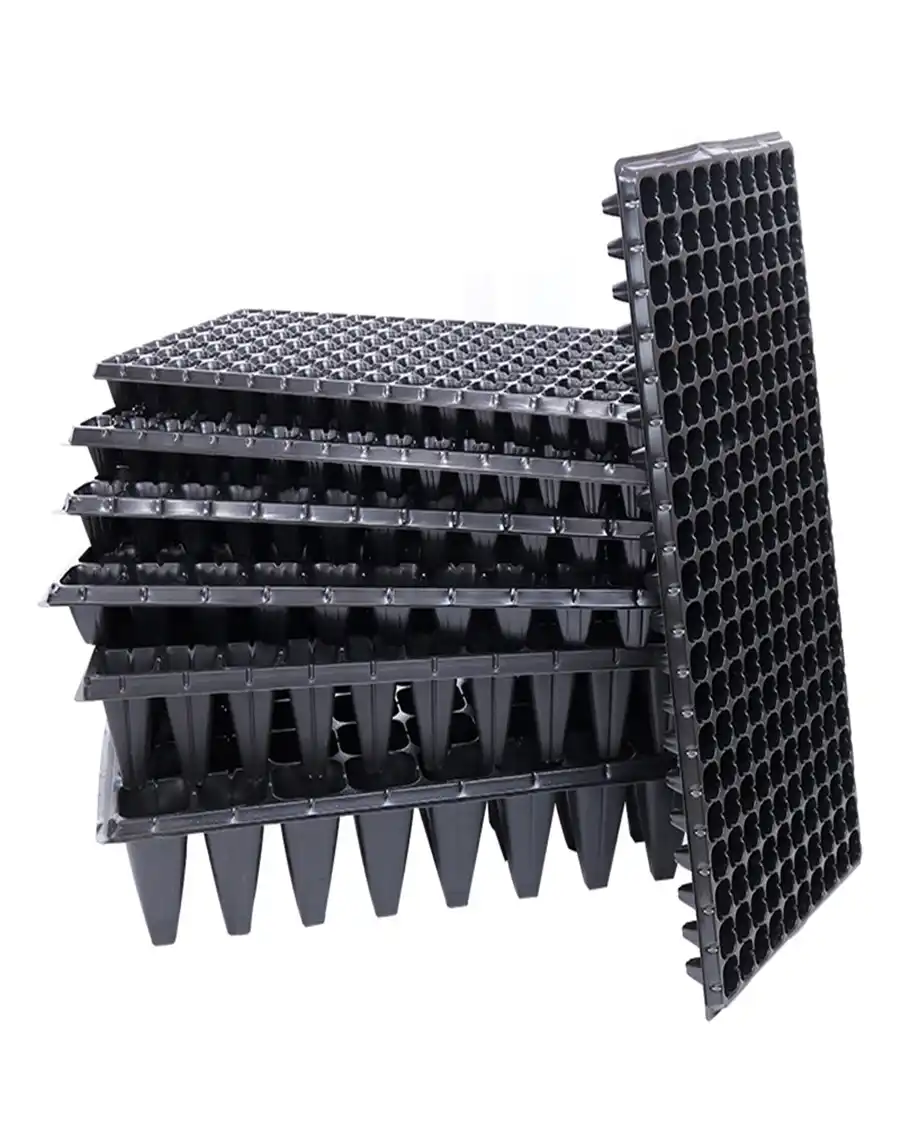

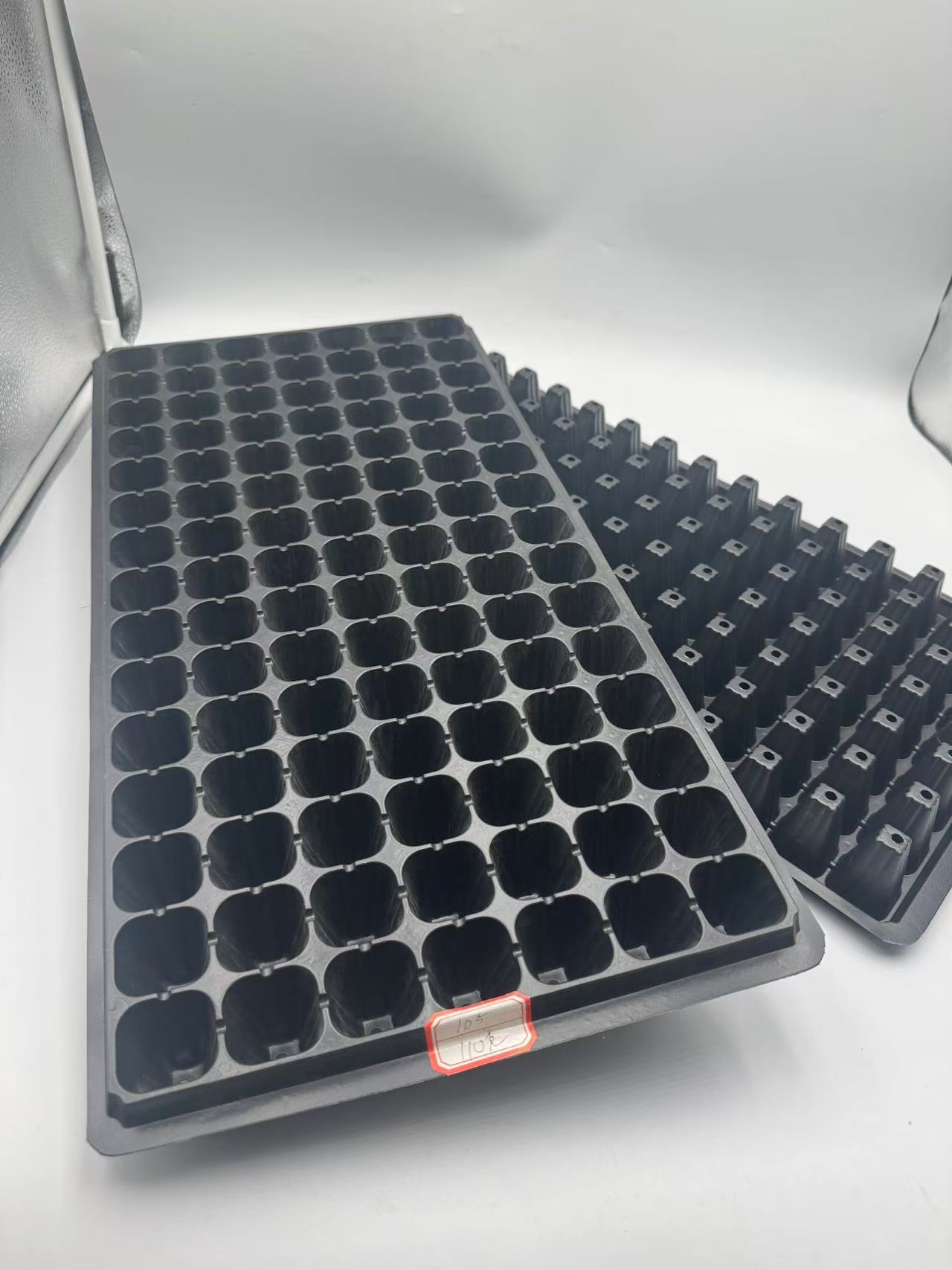

4.1 Design and Structure of Seedling Trays

PS film is used to manufacture seedling trays with a variety of designs and structures. The trays can be designed with different cell sizes and shapes to accommodate various types of seedlings. For example, trays for vegetable seedlings may have smaller cells compared to those for tree seedlings.

4.2 Growth Environment and Seedling Benefits

The various properties of PS film allow it to create an excellent growth environment for seedlings. The ability of PS film to retain moisture keeps the soil in the tray at appropriate moisture levels, hence reducing frequent watering. At the same time, it has limited gas permeability, allowing partial gas

4.3 Reusability and Durability

Most PS seedling trays can be reused.

5. Manufacturing Processes of PS Film

5.1 Extrusion Process

5.1 Extrusion Process

The manufacturing of PS films usually starts with an extrusion process.

5.2 Orientation Process

5.2 Orientation Process

An orientation process is often adopted in order to enhance the mechanical properties of PS film. This involves stretching of the film in one or both directions. Uniaxial orientation refers to the stretching of the film in one direction, while biaxial orientation stretches the film in

both machine and transverse directions. Orientation aligns the polymer chains in the film, thereby increasing its strength, stiffness, and clarity. Bi-oriented PS films have superior dimensional stability, and are better suitable in specific applications that require it for such properties as in food blister packages and seedling trays.

5.3 Coating and Lamination

Coating or laminating PS film with other materials often enhances its performance. The additional barrier coating could improve the barrier of gases and moisture. Particularly in food packaging applications where higher protection is desired, a barrier coating would come in handy.

6. Quality Control and Regulatory Compliance

6. Quality Control and Regulatory Compliance

6.1 Quality Control Measures

In ensuring that the quality of PS film used in the food packaging and seedling tray meets the set standards, strict quality

PS film finds applications in food packaging and seedling trays, subject to a number of regulatory requirements. The regulatory bodies like the FDA in the United States and the EFSA in Europe have set guidelines and standards on the materials used for food packaging.

PS film finds applications in food packaging and seedling trays, subject to a number of regulatory requirements. The regulatory bodies like the FDA in the United States and the EFSA in Europe have set guidelines and standards on the materials used for food packaging.

7. Environmental Impact and Sustainability

7. Environmental Impact and Sustainability

7.1 Environmental Concerns

PS film, like many plastics, has raised environmental concerns. It is nonbiodegradable and takes an awfully long time to decompose within the environment, contributing to plastic pollution.

7.2 Recycling and Waste Management

7.2 Recycling and Waste Management

Several initiatives are in place for improving recycling and waste management of PS film. The recycling of PS film will reduce the demand for virgin material and the amount of wastes to the landfill site. Some recycling facilities are able to collect and process PS film

Researchers and manufacturers are exploring sustainable alternatives to PS film. These include the use of bio-based polymers derived from renewable resources such as plants. It can have similar properties as traditional PS film, but with a reduced environmental footprint. Another approach is the development of composite materials that combine PS with other biodegradable or recyclable materials to improve the overall sustainability of the film. Other ideas are innovations in packaging design, like minimalistic packaging or easily separable and recyclable packaging. Biodegradable plastics and paper pulp trays used in seedling trays are under investigation, which may provide a potentially greener alternative to the horticultural industry.

8. Conclusion

8. Conclusion

PS film is a versatile and useful material in food blister packaging as well as in seedling trays. Properties like transparency, chemical inertness, thermal processability, and barrier properties are some of the reasons why it was used in these applications. In addition, the manufacturing process of PS film has been improved to produce high-quality films with specific properties targeted at meeting diverse needs.

However, the environmental impact of PS film cannot be taken lightly, and effort needs to be made in ways of improving its recyclability and waste management, apart from finding sustainable alternatives for the same. Continuity of research and innovation will reduce the negative environmental impact resulting from PS film, while prolonging the life of this material, which is very useful and beneficial to the food and horticultural industries.

Within 15-20 days after received payment...more