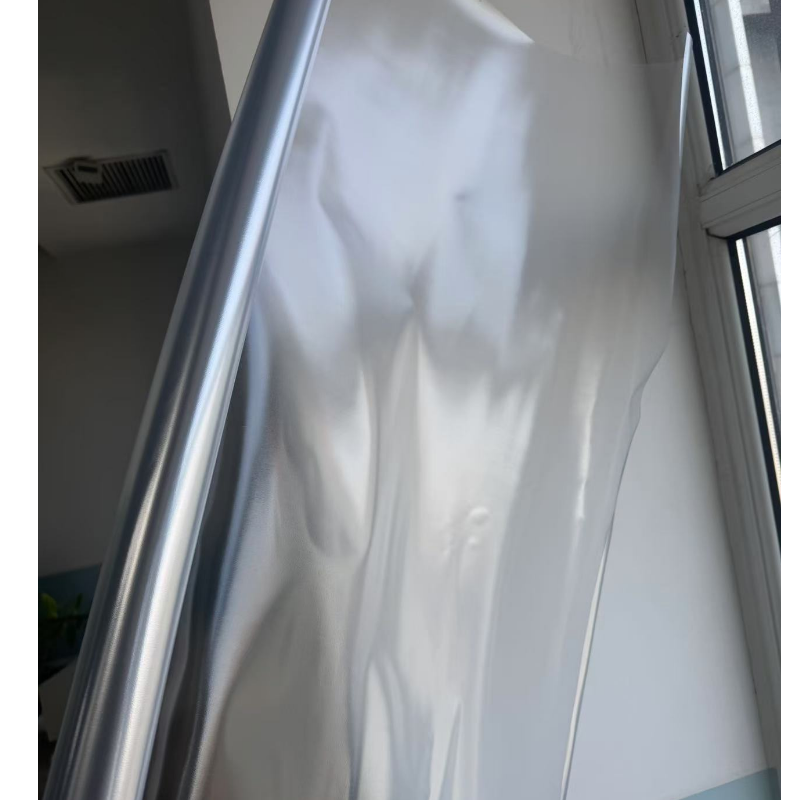

TL-PVC -0068 The Application of Transparent 70 - micron PVC Film in Composite Packaging Introduction

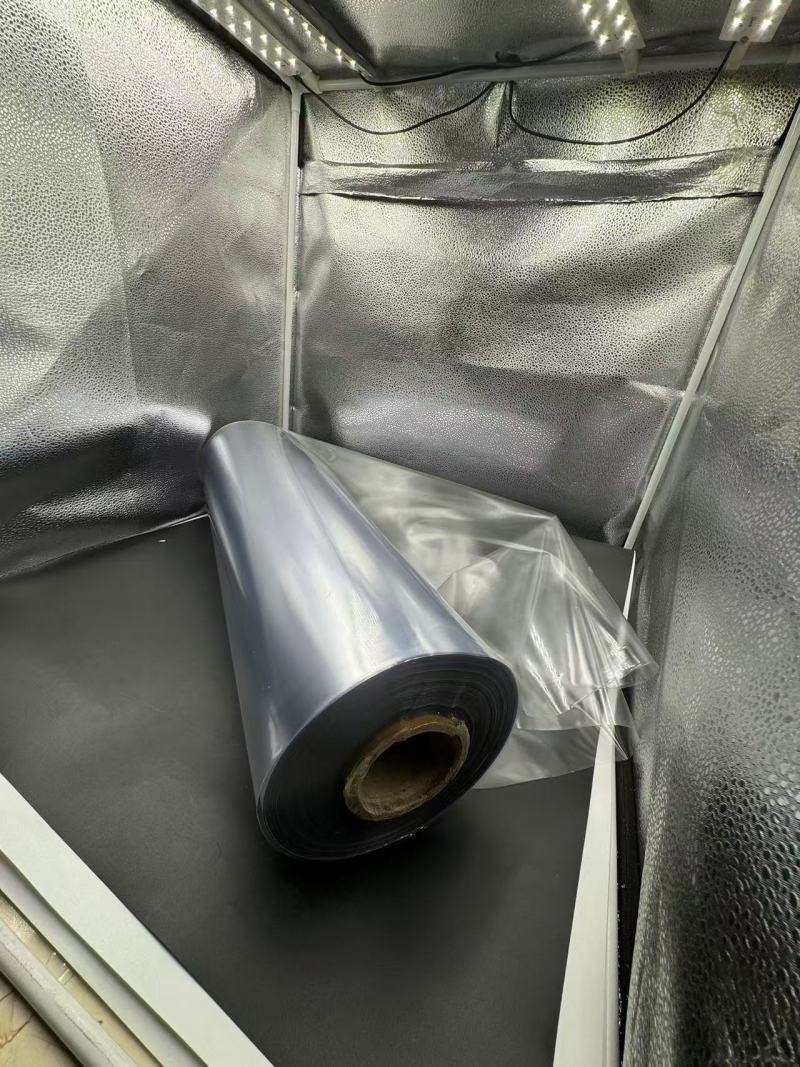

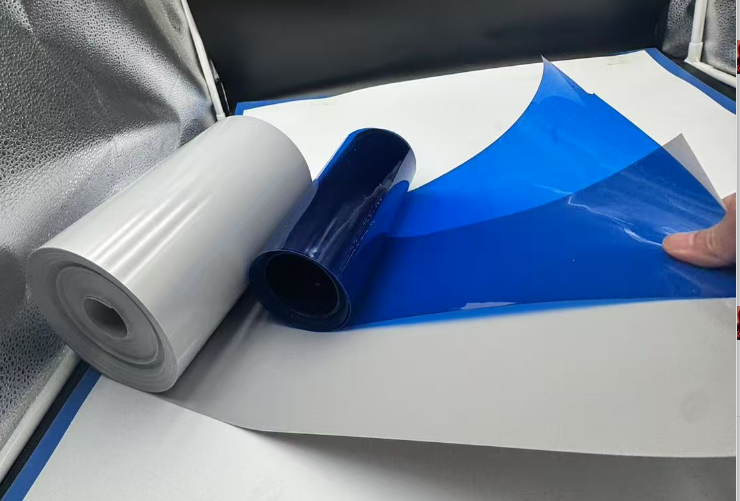

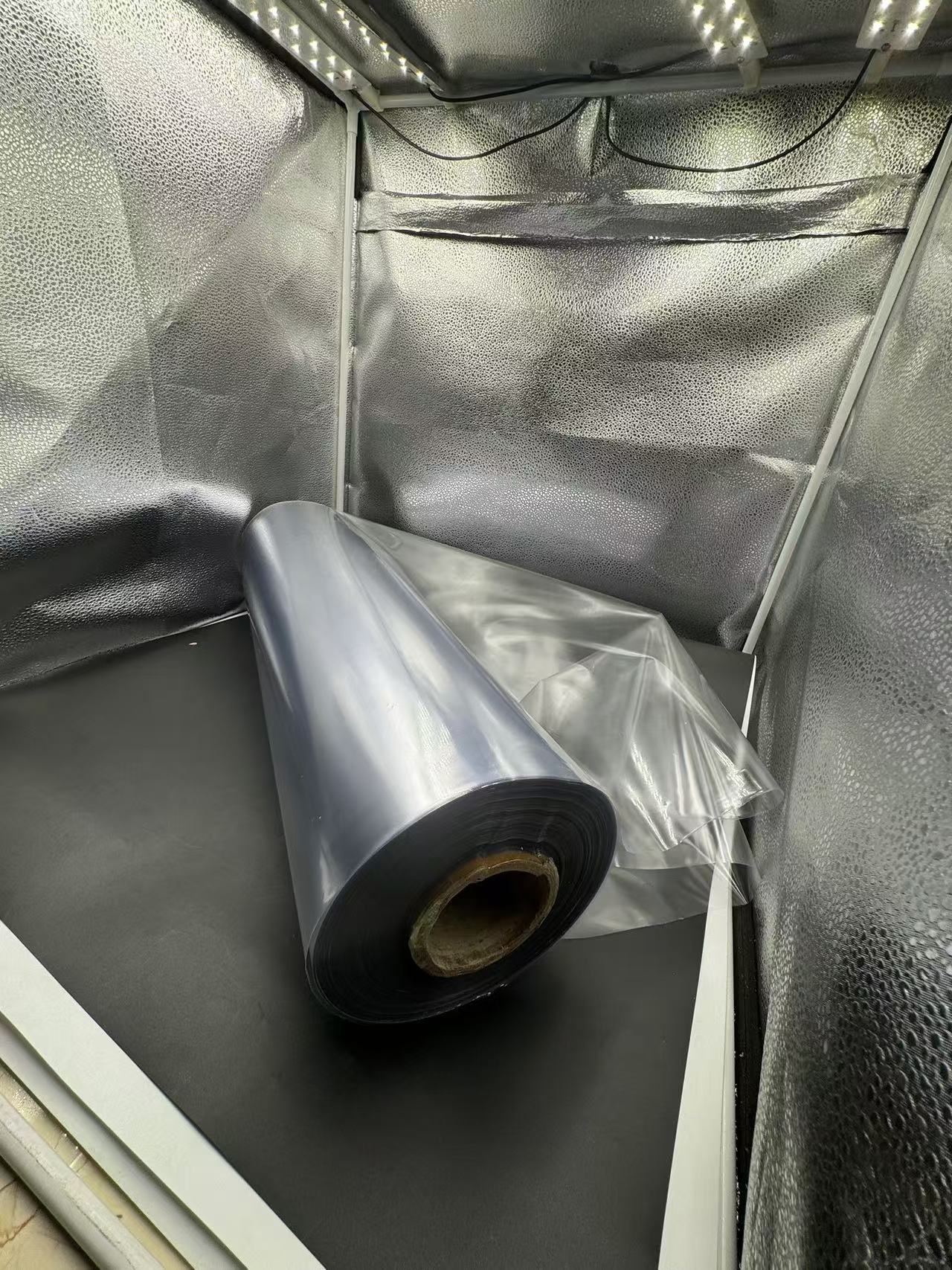

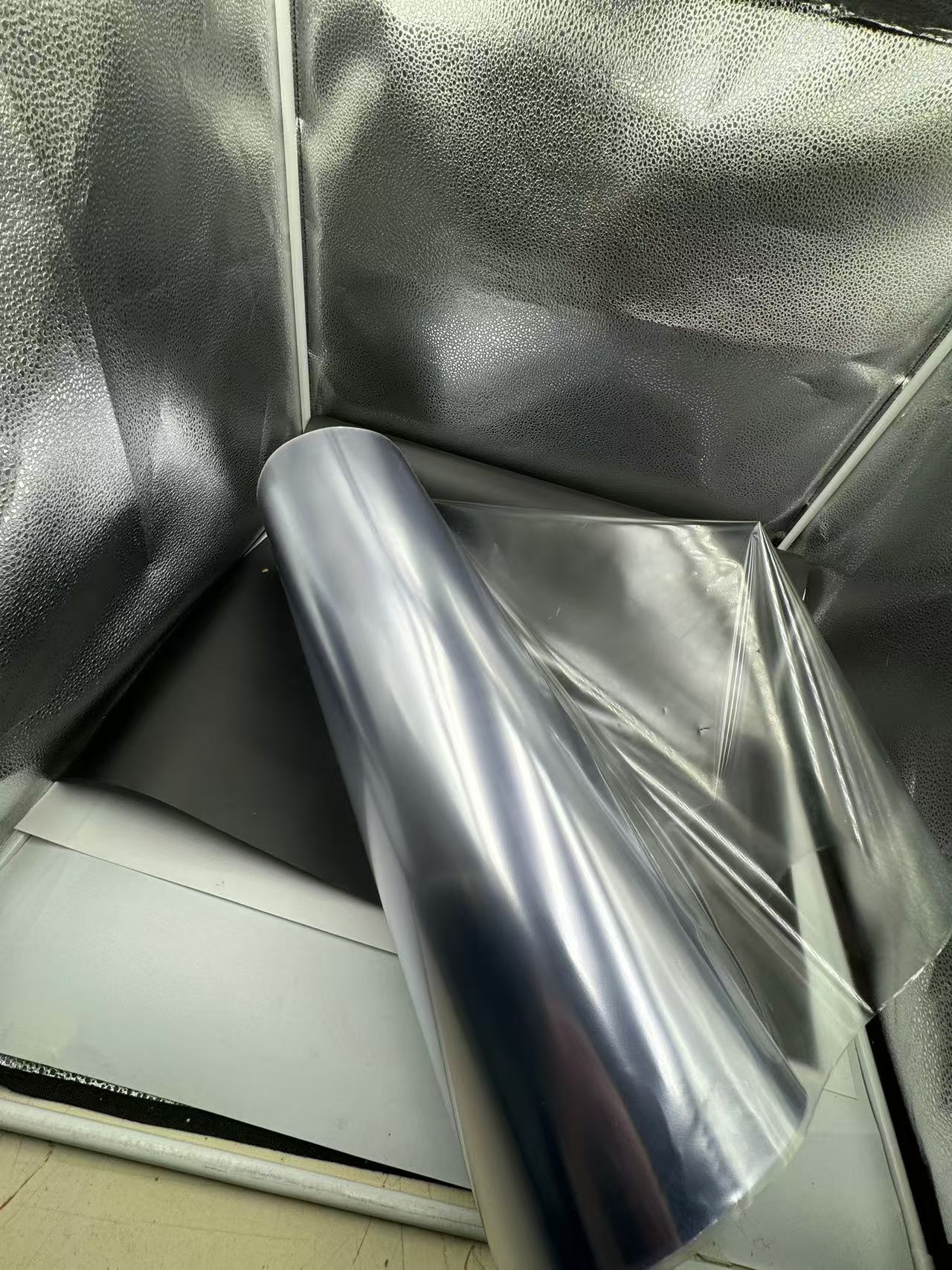

Material: PVC ROLL

Thickness 0.45-0.018mm-customization

Size: 80MM/130MM/Customization

GRADE: pharma grade film

color: white/ customization

location: china

Usage: Pharmaceutical, dried food

- TOPLEADER

- china

- 15WORKING DAYS

- 5000T/M

- Information

- Video

- Download

The Application of Transparent 70 - micron PVC Film in Composite Packaging

Introduction

In the world of packaging, the transparent 70 - micron PVC (polyvinyl chloride) film has emerged as a highly versatile and significant material. Its unique properties make it an ideal choice for various composite packaging applications, revolutionizing the way products are protected, presented, and preserved. This article delves into the detailed exploration of the use of this remarkable film in different aspects of composite packaging.

Material Properties of Transparent 70 - micron PVC Film

Physical Characteristics

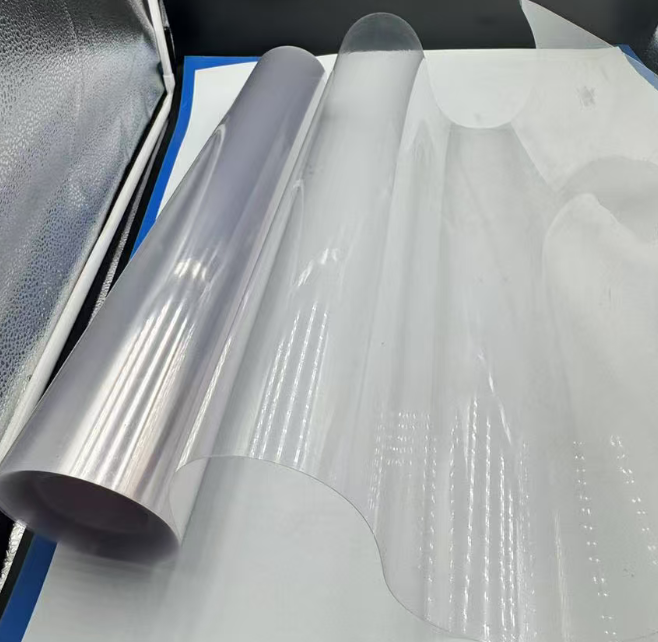

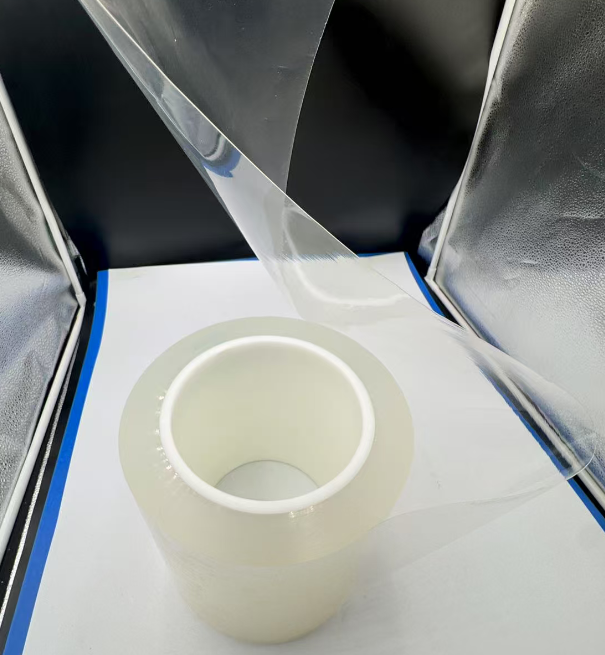

The 70 - micron thickness of the PVC film strikes a perfect balance for many packaging needs. It provides sufficient strength and durability while maintaining flexibility. This thickness allows the film to be easily manipulated during the packaging process, such as folding, sealing, and conforming to the shape of the product. The transparency of the film is one of its most alluring features. It offers a clear view of the contents inside the package, which is crucial for both consumer appeal and product inspection. The high - level transparency is achieved through precise manufacturing processes that control the purity of the PVC and the alignment of its polymer chains.

Chemical Properties

PVC is known for its chemical stability. The 70 - micron PVC film is resistant to many common chemicals, making it suitable for packaging a wide range of products. It can withstand contact with substances like oils, fats, and mild acids or alkalis without significant degradation. This chemical resistance broadens its application scope, enabling it to be used in packaging various consumer goods, food items, and industrial products. However, it is important to note that PVC may not be suitable for all highly reactive or corrosive substances, and proper compatibility testing should be conducted for specific applications.

Mechanical Properties

The mechanical strength of the 70 - micron PVC film is remarkable. It has good tensile strength, which means that it can endure stretching and pulling forces during handling and transportation. This property is essential for preventing the film from tearing or breaking under normal stress conditions. Additionally, the film has a certain degree of elasticity, allowing it to absorb shocks and impacts. This is particularly valuable when packaging delicate or fragile products, as the film can act as a cushion to protect the contents from damage.

Barrier Properties

In composite packaging, barrier properties are of utmost importance. The 70 - micron PVC film offers decent barrier capabilities against moisture, gases, and other environmental factors. It can effectively reduce the ingress of moisture, which is crucial for protecting products that are sensitive to humidity. For example, in the packaging of certain food products or electronic components, preventing moisture absorption can significantly extend the product's shelf life or maintain its functionality. The film also provides some resistance to gases such as oxygen and carbon dioxide, although for applications requiring high - level gas barrier properties, additional coatings or laminations may be necessary.

Manufacturing Process of Transparent 70 - micron PVC Film

Raw Material Preparation

The production of 70 - micron PVC film starts with the selection of high - quality PVC resin. The resin is carefully chosen based on its molecular weight, degree of polymerization, and other characteristics that influence the final film's properties. Along with the PVC resin, various additives are incorporated. These include plasticizers to improve the flexibility of the film, stabilizers to enhance its thermal stability and prevent degradation during processing and storage, and lubricants to facilitate the extrusion process. The selection and proportion of these additives are critical in determining the quality and performance of the final PVC film.

Extrusion Process

Once the raw materials are prepared, they are mixed thoroughly and fed into an extruder. The extruder heats the mixture to a molten state under carefully controlled temperature and pressure conditions. The temperature profile within the extruder is adjusted to ensure uniform melting of the PVC resin and proper dispersion of the additives. The molten PVC is then forced through a die with a specific gap to form a continuous sheet of film. The die design and the extrusion speed are precisely controlled to achieve the desired 70 - micron thickness. During the extrusion process, the molten film is also subjected to cooling and calibration systems to maintain its uniformity and dimensional stability.

Calendering or Casting (Optional)

In some manufacturing processes, the extruded PVC film may undergo either calendering or casting. Calendering involves passing the film through a series of rollers to further refine its thickness, smoothness, and surface quality. This process can improve the mechanical properties and appearance of the film. Casting, on the other hand, is a method where the molten PVC is spread onto a moving belt or drum to form the film. This technique can be used to achieve specific surface textures or to incorporate additional layers or coatings during the film - forming process.

Quality Control and Finishing

After the film is formed, it undergoes rigorous quality control procedures. The thickness of the film is measured using precision instruments to ensure it meets the 70 - micron specification. The transparency, mechanical strength, and barrier properties are also tested. Any defects or non - conformities are identified and corrected. The film may then be wound onto rolls for storage or further processing. In some cases, additional finishing operations such as surface treatment to improve printability or the application of anti - static coatings may be carried out to enhance the film's functionality in composite packaging applications.

Applications of Transparent 70 - micron PVC Film in Composite Packaging

Food Packaging

Bakery Products

In the bakery industry, transparent 70 - micron PVC film is widely used for packaging various items. For example, it is used to package cakes, pastries, and bread. The transparency of the film allows consumers to see the delicious and visually appealing products inside. The film's moisture barrier property helps to keep the baked goods fresh by preventing them from drying out. For cakes with frosting or delicate fillings, the film's flexibility and gentle touch ensure that the decoration and structure of the cake are not damaged. In composite packaging, the PVC film can be laminated with other materials such as paperboard to provide additional strength and rigidity for better protection during transportation and display.

Meat and Poultry Packaging

For meat and poultry products, the 70 - micron PVC film plays an important role. It is often used in combination with absorbent pads and other packaging materials. The clear film allows consumers to assess the quality and freshness of the meat, such as its color and texture. The film's ability to resist puncture and its mechanical strength protect the meat from damage during handling. The moisture and gas barrier properties are crucial in preventing spoilage by reducing the growth of bacteria and maintaining the proper environment around the meat. In some cases, the PVC film may be part of a multi - layer composite package that includes oxygen - scavenging layers to further extend the shelf life of the meat.

Fresh Produce Packaging

Fresh fruits and vegetables also benefit from the use of 70 - micron PVC film in composite packaging. The film can be used to create bags or wraps for individual fruits or groups of produce. The transparency enables consumers to select the best - looking products. The film's ability to control moisture and gases helps to maintain the freshness of the produce. For example, in the case of tomatoes, the PVC film can slow down the ripening process by regulating the exchange of gases. In composite packaging, the PVC film can be combined with breathable materials to create an optimal environment for the produce.

Consumer Goods Packaging

Cosmetics Packaging

In the cosmetics industry, transparent 7C - micron PVC film is used in various ways. It can be used to package lipsticks, compacts, and small bottles of creams or perfumes. The clear film allows consumers to see the product's color, design, and other details, which is important for marketing purposes. The film's chemical resistance ensures that it does not react with the cosmetic products, which often contain a variety of ingredients such as oils, waxes, and pigments. In composite packaging, the PVC film can be laminated with cardboard or plastic trays to provide a more stable and attractive packaging solution.

Toys Packaging

Toys are often packaged using 70 - micron PVC film in combination with other materials. The clear film allows children and parents to see the toy inside, which can increase the appeal of the product. The film's mechanical strength protects the toy from damage during transportation and storage. It can be used to create blister packs or windowed boxes. In composite packaging, the PVC film can be combined with printed cardboard to display product information and branding. The flexibility of the film also allows it to conform to the shape of the toy, providing a snug fit.

Electronics Packaging

For electronic products such as mobile phones, tablets, and small accessories, 70 - micron PVC film is used in composite packaging. The film's anti - static properties (if treated) are crucial for protecting sensitive electronic components from electrostatic damage. The transparency allows for easy inspection of the product during quality control and by the end - user. The film's moisture and chemical resistance protect the electronics from environmental factors. In composite packaging, the PVC film can be laminated with foam or other cushioning materials to provide shock absorption during transportation.

Industrial Product Packaging

Small Parts and Hardware Packaging

In the industrial sector, 70 - micron PVC film is used for packaging small parts and hardware items. The film's transparency allows for easy identification of the parts, which is important in inventory management and assembly processes. The film's mechanical strength and puncture resistance protect the parts from damage and prevent them from getting lost. In composite packaging, the PVC film can be combined with plastic or cardboard dividers to keep the parts organized within a larger package.

Chemical and Lubricant Packaging

For packaging chemicals and lubricants, the 70 - micron PVC film's chemical resistance comes into play. It can be used to package small bottles or containers of these products. The film can prevent leakage and protect the contents from external contamination. In some cases, the PVC film may be part of a multi - layer composite package that includes additional barrier layers for enhanced protection against chemical reactions or gas permeation.

Advantages of Transparent 70 - micron PVC Film in Composite Packaging

Visual Appeal and Product Display

The transparency of the 70 - micron PVC film is a significant advantage in composite packaging. It allows for excellent product display, making the products more attractive to consumers. Whether it's food, cosmetics, or toys, the clear view of the product inside the package can influence purchasing decisions. The film acts as a showcase, highlighting the quality and features of the product. This visual appeal is enhanced in composite packaging when combined with other materials that can provide a more luxurious or branded look.

Protection of Contents

The 70 - micron PVC film offers robust protection to the packaged products. Its mechanical strength, moisture barrier, and gas barrier properties work together to safeguard the contents. It can prevent physical damage, moisture - induced spoilage, and oxidation. In composite packaging, when combined with other materials, the overall protection level can be further enhanced. For example, combining the PVC film with cushioning materials can provide better shock protection, and laminating it with high - barrier materials can improve gas and moisture resistance.

Versatility in Packaging Design

The flexibility and ease of processing of the 70 - micron PVC film make it highly versatile in packaging design. It can be used in various forms such as bags, wraps, blister packs, and windowed boxes. It can be combined with different materials to create custom - designed composite packages. This versatility allows packaging designers to meet the specific requirements of different products and industries. The film can be easily printed on, laminated, or sealed, enabling the creation of unique and functional packaging solutions.

Cost - effectiveness

PVC film is relatively cost - effective compared to some other packaging materials with similar properties. The manufacturing process of 70 - micron PVC film can be optimized for large - scale production, resulting in lower costs. In composite packaging, the use of PVC film can help reduce the overall packaging cost while still providing satisfactory performance. This cost - advantage makes it an attractive option for many manufacturers, especially when packaging products in high volumes.

Compatibility with Other Packaging Materials

The 70 - micron PVC film has good compatibility with a wide range of other packaging materials. It can be laminated with paperboard, cardboard, plastics, and foams without significant issues. This compatibility allows for the creation of composite packages that combine the best features of different materials. For example, combining PVC film with paperboard can provide a rigid and printable surface, while the PVC film adds transparency and moisture resistance.

Challenges and Solutions in Using Transparent 70 - micron PVC Film in Composite Packaging

Environmental Concerns

One of the main challenges associated with PVC is its environmental impact. PVC is not easily biodegradable, and the disposal of large amounts of PVC - based packaging can be a problem. To address this, manufacturers can explore recycling options. Some recycling programs have been developed to collect and recycle PVC film. Additionally, efforts can be made to reduce the use of PVC in packaging by finding alternative materials or using thinner PVC films when possible. Another approach is to use PVC in more sustainable composite packaging designs, such as combining it with biodegradable materials.

Regulatory Compliance

In some industries, there are strict regulations regarding the use of PVC in packaging. For example, in the food and pharmaceutical industries, there are specific requirements related to the safety and quality of packaging materials. Manufacturers using 70 - micron PVC film in these applications need to ensure that the film complies with relevant regulations. This may involve conducting tests to prove the absence of harmful substances that could migrate into the product and ensuring that the film meets the required barrier and mechanical properties for the specific product.

Compatibility with Specific Products

While PVC film has good general compatibility with many products, there may be some specific products that have issues with PVC. For example, some highly acidic or alkaline substances may interact with the PVC over time. To overcome this, manufacturers can conduct compatibility tests for each product before using PVC film in its packaging. If there are compatibility issues, alternative packaging materials or additional protective layers can be considered. In some cases, special coatings can be applied to the PVC film to improve its compatibility with specific products.

Conclusion

Transparent 70 - micron PVC film has proven to be an invaluable material in the world of composite packaging. Its unique combination of physical, chemical, and mechanical properties makes it suitable for a wide range of applications in the food, consumer goods, and industrial product packaging sectors. Despite the challenges related to environmental impact, regulatory compliance, and product compatibility, the advantages of this film in terms of visual appeal, product protection, versatility, cost - effectiveness, and compatibility with other materials far outweigh the drawbacks. With continued innovation in manufacturing processes and a focus on sustainable packaging solutions, the use of transparent 70 - micron PVC film in composite packaging is expected to continue to evolve and play an important role in meeting the diverse packaging needs of different industries. Manufacturers, packaging designers, and consumers alike can benefit from the unique features of this remarkable packaging material as it continues to be refined and optimized for various applications.

Within 15-20 days after received payment...more