Rigid PVC Film for pharmaceutical Blister Packaging

Rigid PVC Film Blister Packaging

PVC

Widely used in pharmaceutical food cosmetic industries .

● Common specifications:

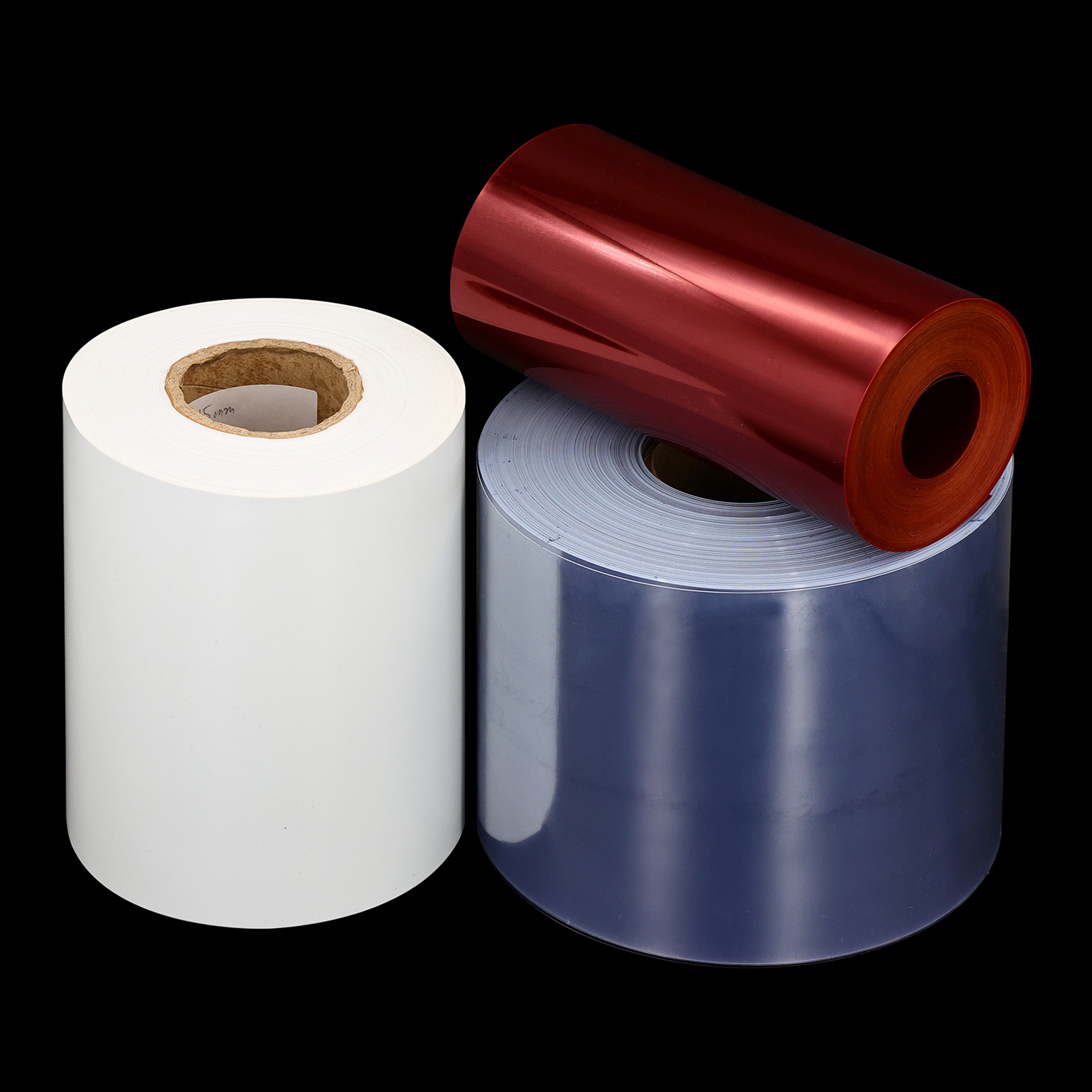

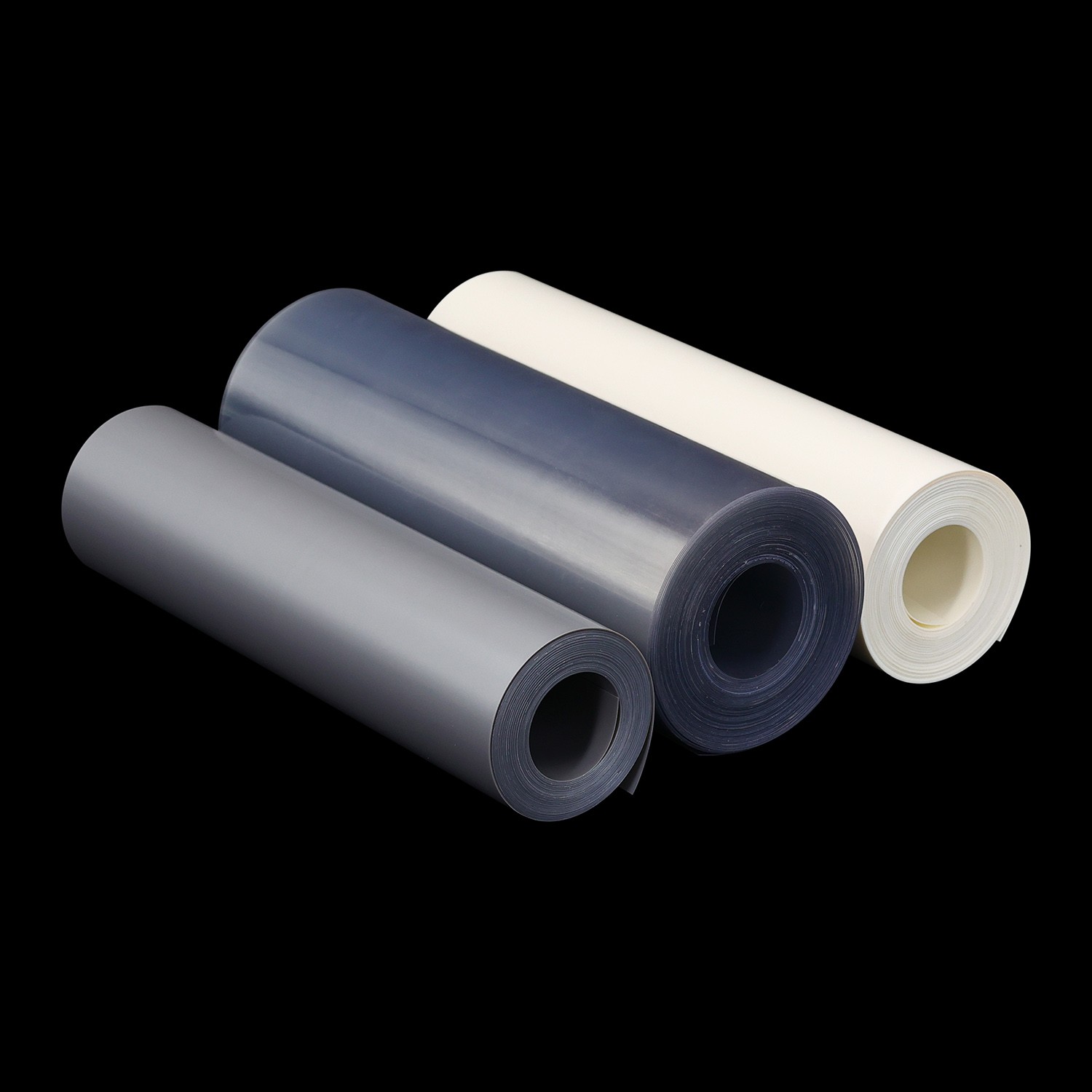

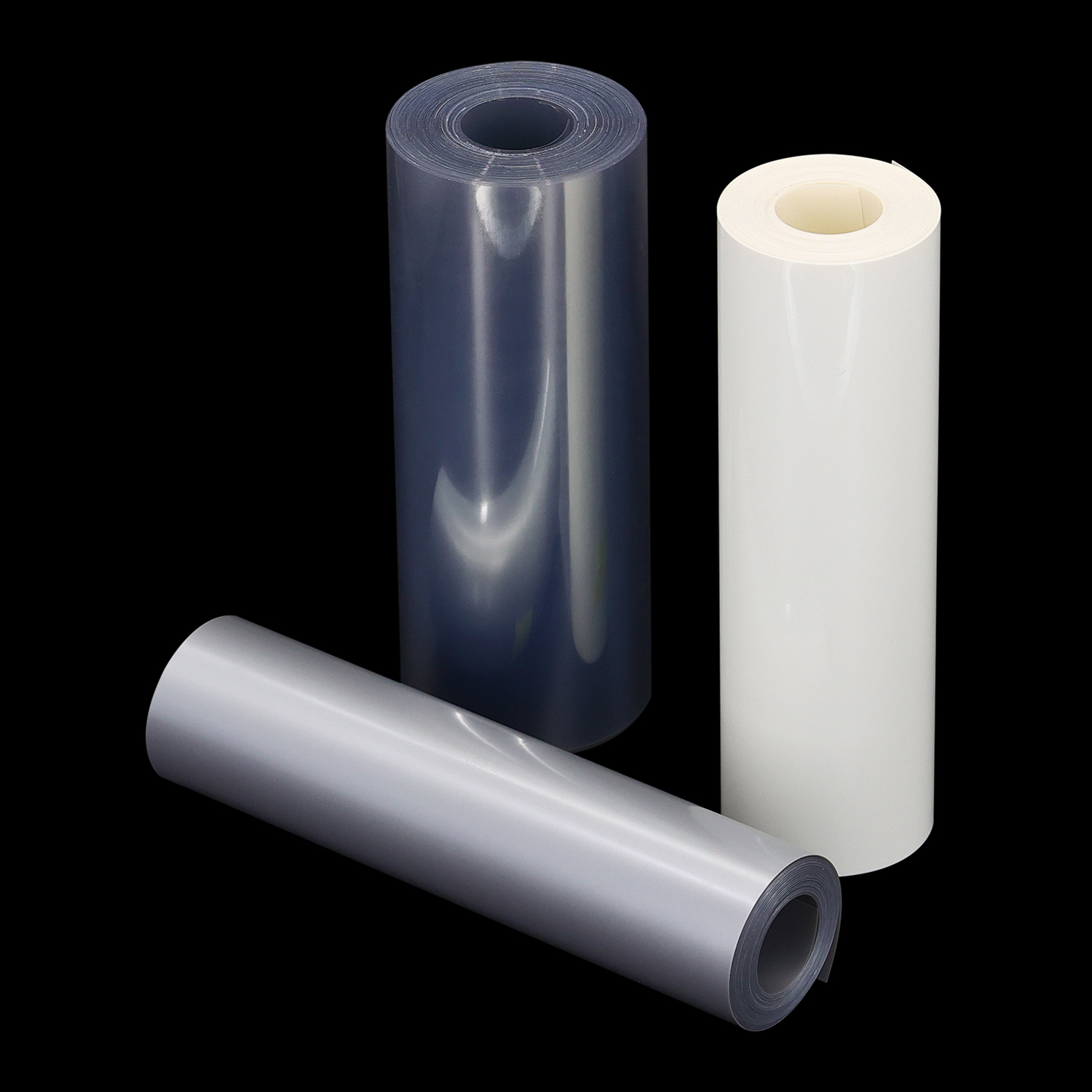

PVC thickness 0.1-0.5mm width 55-1200mm

Colors as the need of clients

- Top Leader

- China

- 12 days

- 2000 tons/month

- Information

- Video

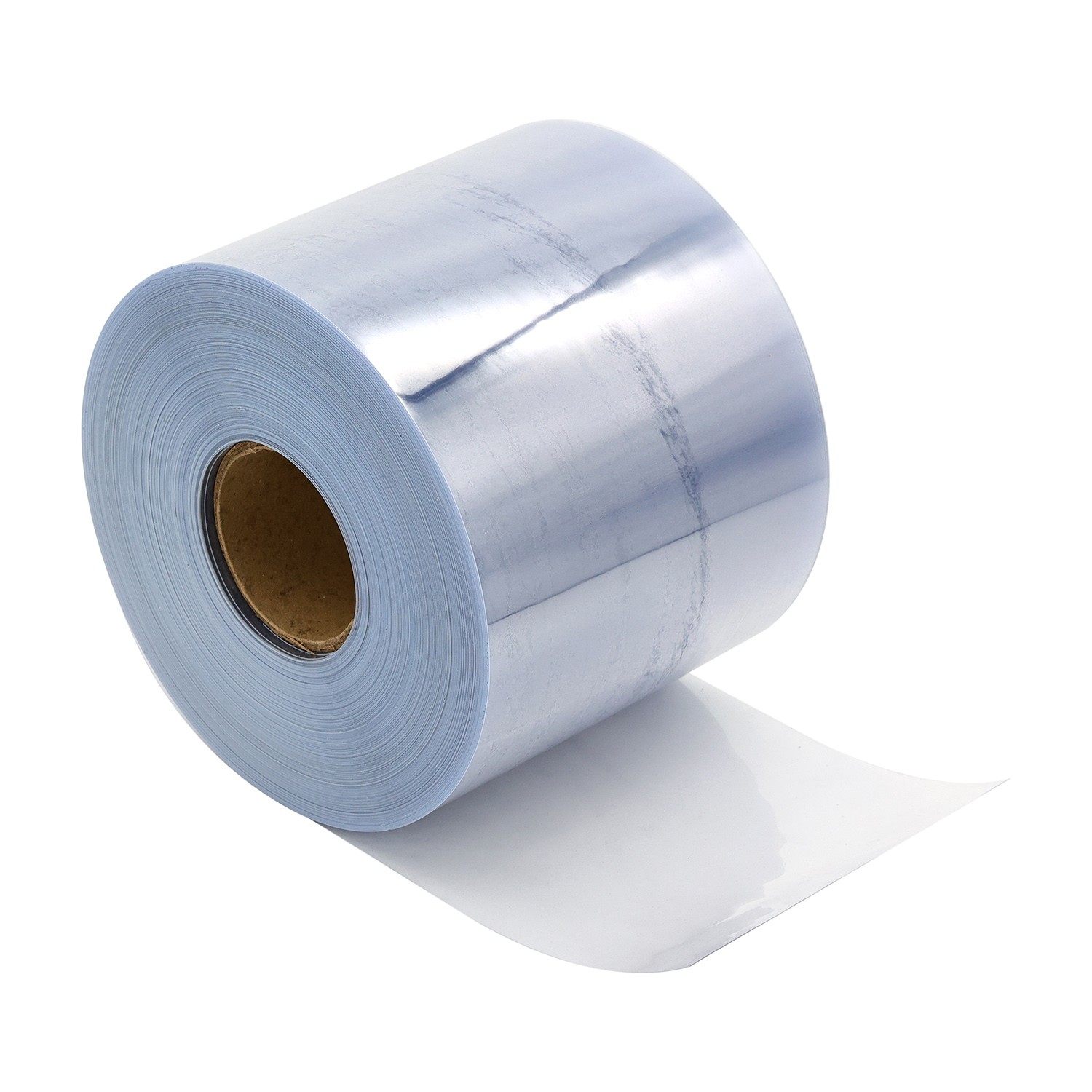

Sound health is always packed in non-toxic and chemical-free foods and pharmaceutical drugs. For the best packaging, TOPLEADERPLASTIC manufactures the excellent rigid PVC film leveraging pharma-grade raw materials and latest calendaring process. The films are manufactured under controlled environment as per current GMP norms and comply with all the food and pharma packaging regulations.

The modern packaging solution by TOPLEADERPLASTIC ranges from 50 to 700 microns and require less fuel in manufacturing and transport as opposed to metal, glass or other materials. That’s increasing its usage and demand in the packaging across the world.

Product Features:

Enable radiation sterilization

Best-in- class thermoforming

Available in varied sizes and color shades

Finest organoleptic properties so the taste and odor is neutral

Remarkable heat-sealing properties

High dimension stability

Gas transmission and moisture rates are low

Appreciable vacuum formation, toughness, and durability

TECHNICAL SPECIFICATION OF RIGID PVC FILM(BLISTER PACKAGING)

| nO. | PARAMETERS | TEST METHOD | UNIT | STANDARD |

|---|---|---|---|---|

| 01 | Color / Appearance | Visual | — | As per Standard Specimen |

| 02 | Thickness of PVC film | DIN 53479 | Micron | 60 TO 100 ± 12 %, 101 TO 200 ± 10 %,201 TO 400 ± 7 %,401 TO 800 ± 5 % |

| 03 | Density | DIN 53479 | g/ cm 3 | 1.35 ± 0.02 |

| 04 | Tensile Strength | DIN EN ISO527 | Kg/cm2 (Min) | 450 |

| 05 | Dimensional Stability MD | DIN 53377 | % (Max) | 60 TO 100 -12 max, 101 TO 200 – 10 max,201 TO 400 -7 max,401 TO 800 – 5 max |

| 06 | Dimensional Stability TD | DIN 53377 | 60 TO 100 + 5 max,101 TO 200 + 3 max,201 TO 400 + 2 max,401 TO 800 + 1 max | |

| 07 | Width tolerance | mm (Max) | ± 1 | |

| 08 | Vicat Softening Point | ASTM –D 1525 | °C | 74 ± 2 |

| 09 | Identification | FTIR | — | To comply |

Within 15-20 days after received payment...more