Harnessing Polycarbonate Sheets for Superior Fire Safety: An In-Depth Analysis

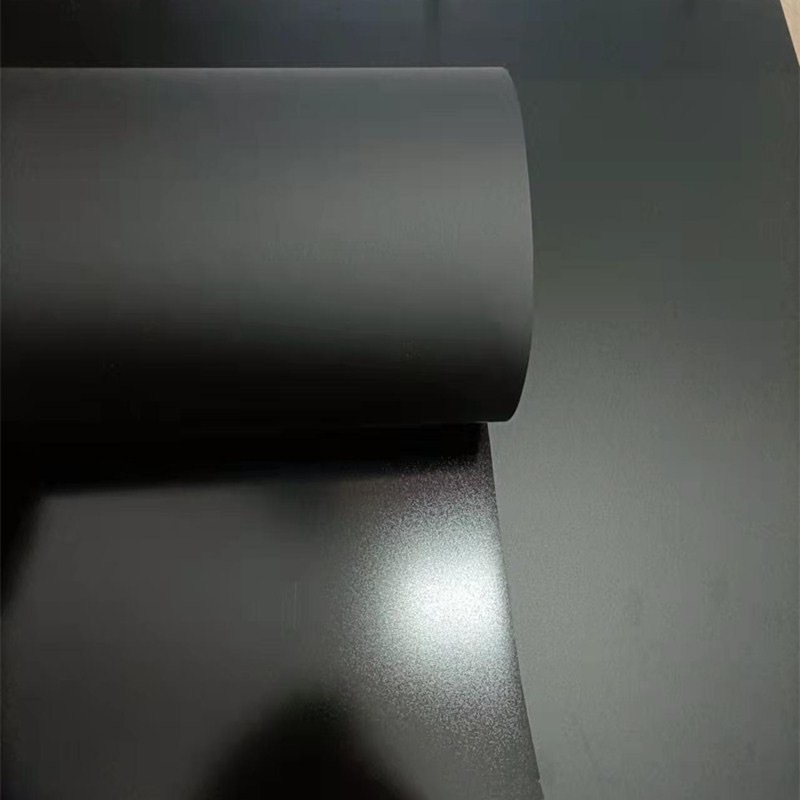

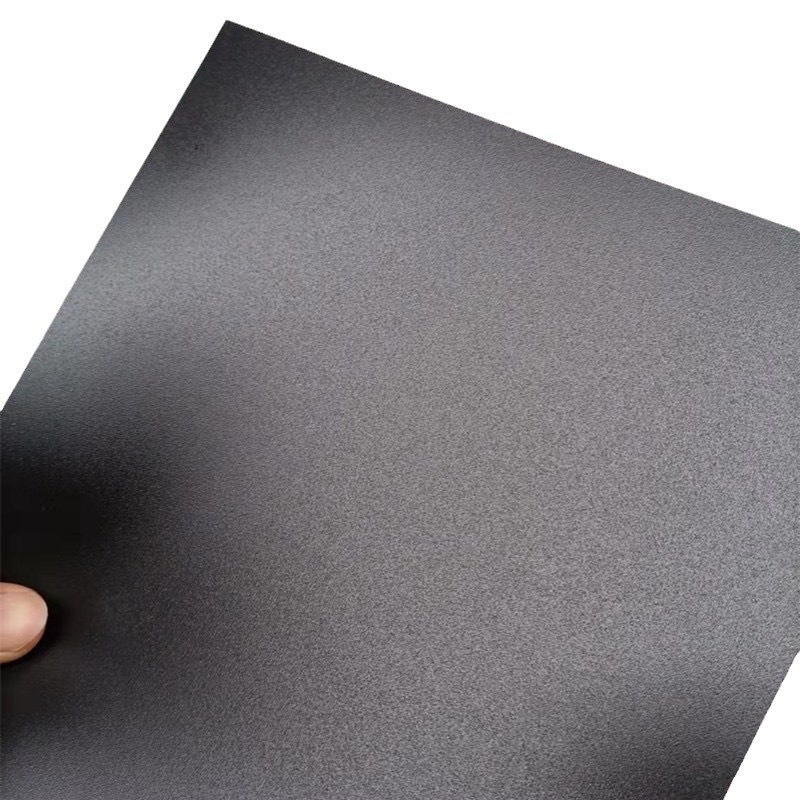

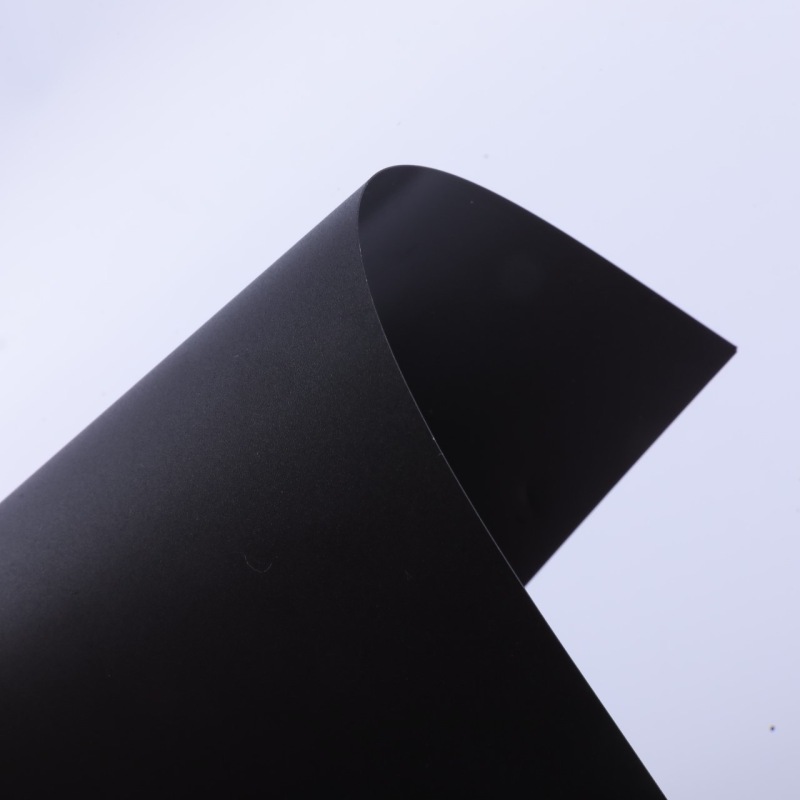

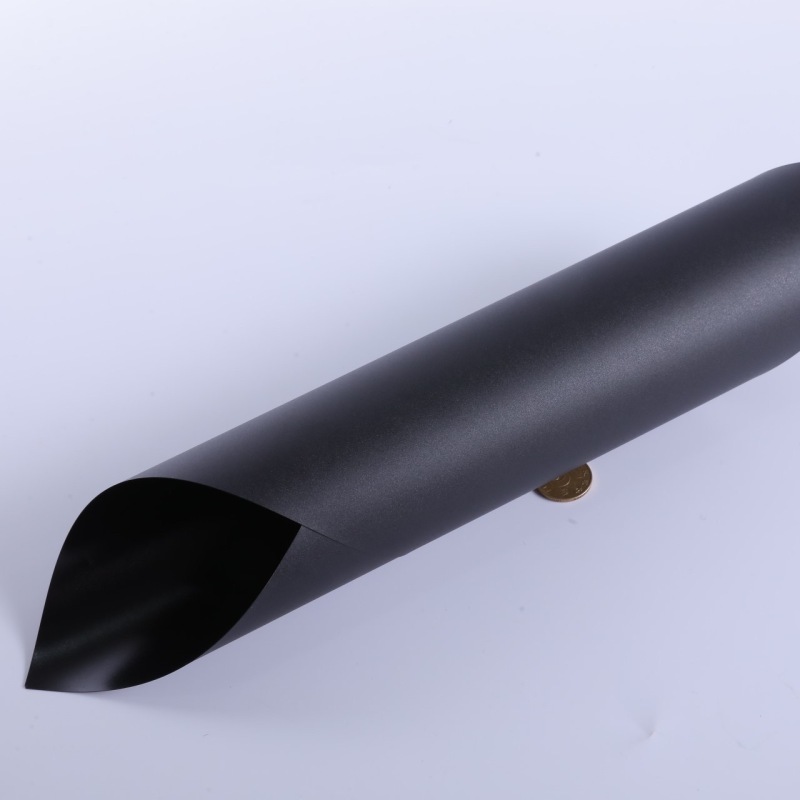

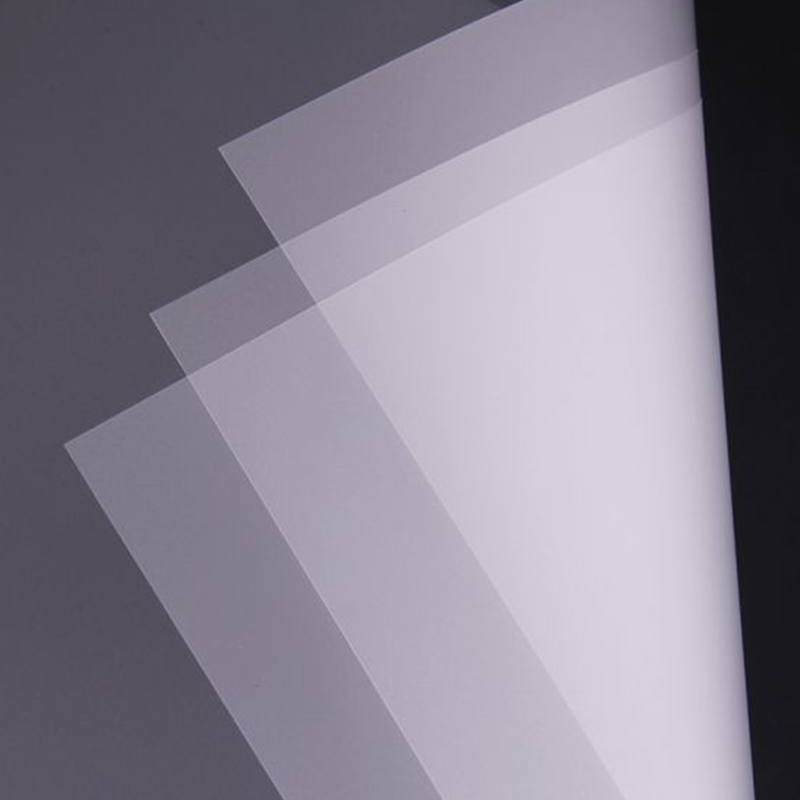

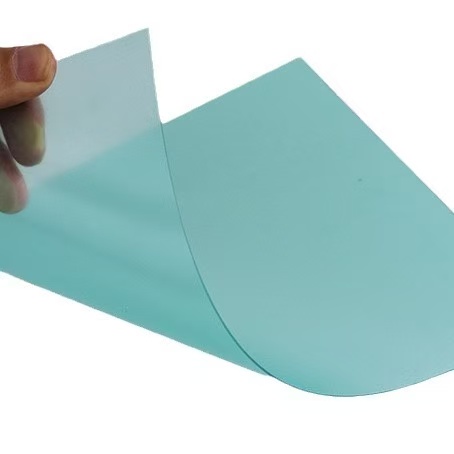

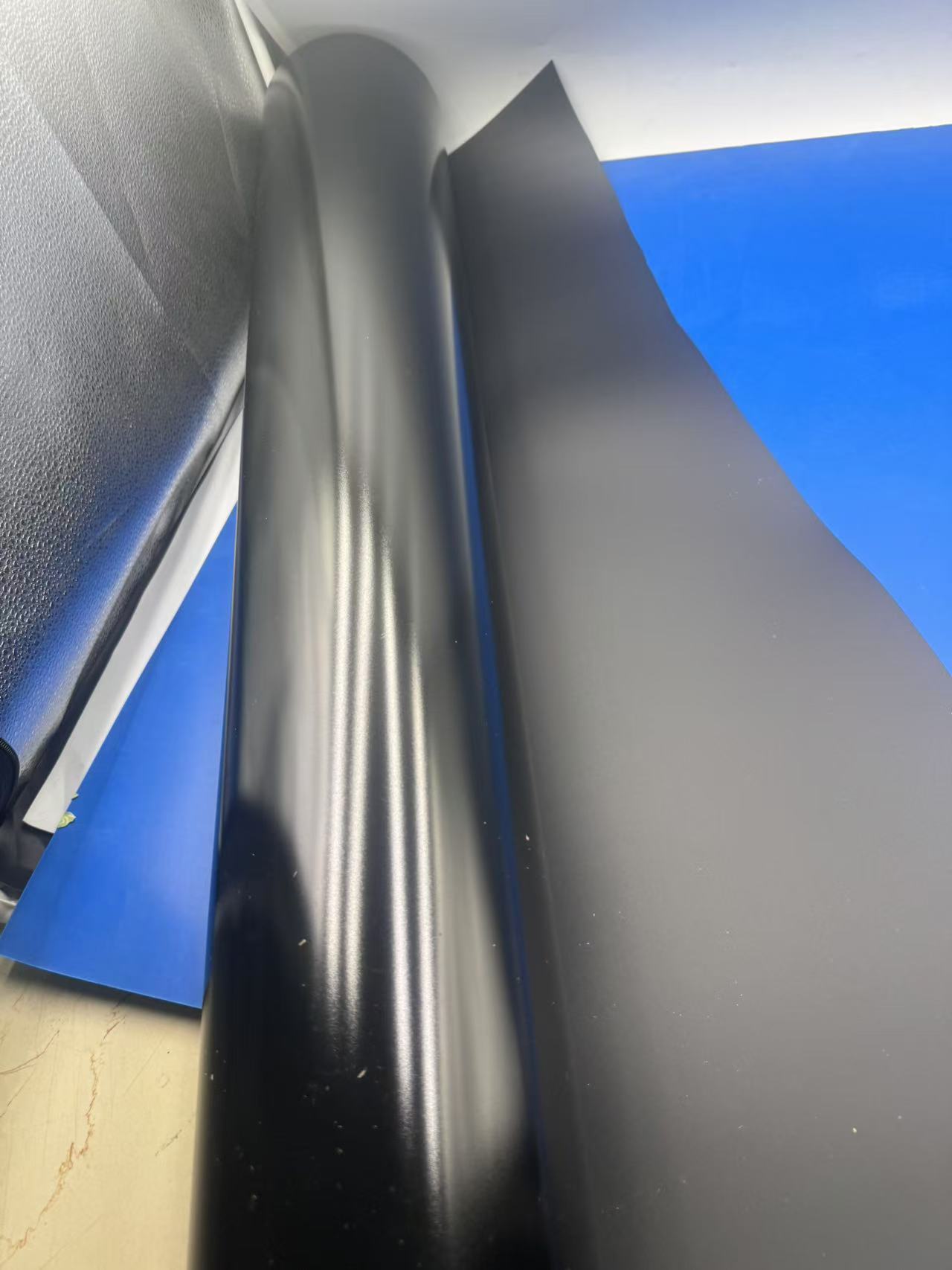

Material: PC sheet

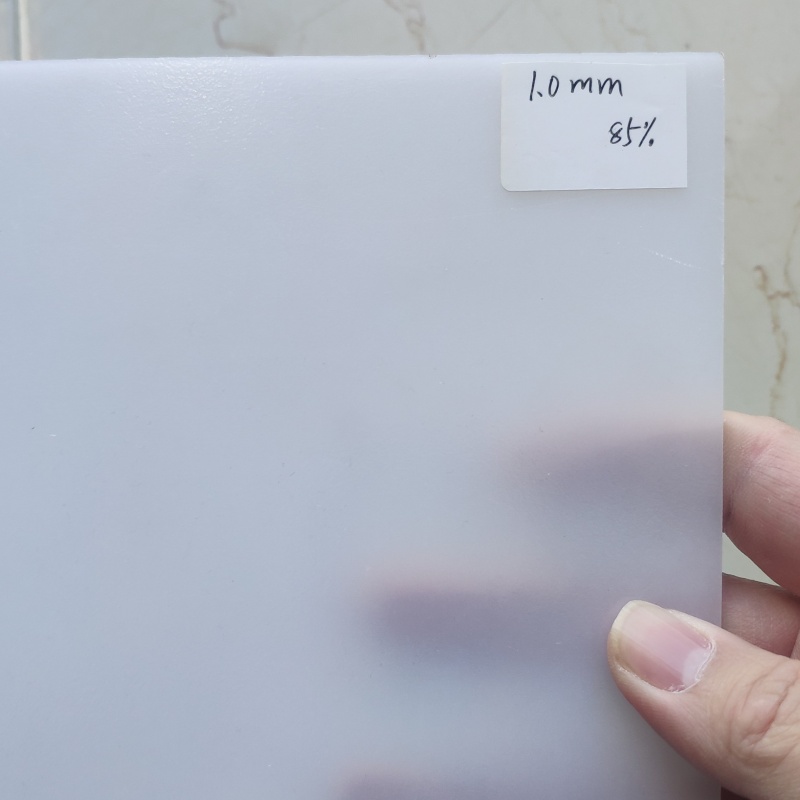

Thickness 0.18mm/customization

Size: A4/100MM Customization

GRADE: HIGH grade film

color: white/ BLACK/ CLEAR customization

location: china

USAGE: for PRINTING, anti flame,

- TOPLEADER

- 中国

- 15WORKING DAYS

- 5000T/M

- Information

The Use of Polycarbonate Sheets in Fire Retardant Applications

Introduction

In case the reason can be solely attributable to a host of singular and unique properties the material has, PC sheets can start to play a very important part in a variety of applications. Usage of PC sheets for fire retardation applications will, with this article, start with the overview of their attributes and uses and proceed through a detailed review of the science of just such features in contributing to fire prevention and safety. Characteristics of Material - Polycarbonate

Polycarbonate is a very strong and versatile thermoplastic polymer. Herein are the reasons why it is particularly suited for fire-retardant applications: High Impact Resistance: PC sheets are virtually unbreakable, offering a safety advantage over glass in areas where fire might compromise structural integrity. Transparency: Like glass, PC can be transparent, allowing for applications where visibility is critical even in fire-prone environments.

Self-Extinguishing Nature: Under appropriate conditions, polycarbonate has a self-extinguishing property, which is considered important for fire safety. While it may melt upon exposure to flame, it does not burn, thus limiting the spread of fire.

Fire Ratings: In many cases, PC sheets receive high fire ratings, such as B1 by the DIN 4102 standards because of their tendency not to burn when exposed to flames. This is a big plus in locations where fire codes are not taken lightly.

Fire Retardant Mechanisms in Polycarbonate

The fire-retarding tendencies of polycarbonate do not entirely come from its base polymer but are enhanced through some mechanisms:

Flame Retardant Additives: Flame-retardant compounds are added to the polymer matrix by manufacturers. These additives work either by releasing non-flammable gases while being heated and diluting the fuel in the gas phase, or by forming a char layer that shields the underlying material from further combustion.

The following are some factors related to physical and chemical structures of PC sheets to resist fire:

Physical Structure: The structure of PC sheets can be modified to include layers or coatings that enhance fire resistance. For instance, co-extruded layers can contain fire-retardant materials on the surface, providing an additional barrier against fire.

Chemical Formulation: The molecular structure of polycarbonate can be altered during manufacturing to resist ignition, particularly by incorporating halogenated or phosphorus-based compounds that interfere with the combustion process.

Applications of Fire Retardant PC Sheets

The fire-retarding properties of polycarbonate make it suitable for a wide variety of applications, including architectural glazing. In skyscrapers, shopping centers, or any public buildings where fire safety is paramount, the use of PC sheets serves as a safer alternative to traditional glass. They are used for skylights, partitions, or as facade elements where fire regulations specify materials that must not contribute significantly to fire spread.

Transportation-PC sheets applied in windows, partitions, and interior components of trains, buses, and airplanes. In these transport facilities, the resistance against fire is very important due to the great disasters that the spread of fire may cause. PC sheets meet standards like FAR 25.853 in such applications that are vital for aviation safety.

Electrical and Electronics: The flame-retardant nature of PC makes it perfect for housing electrical components where circuit fires might occur. It's used in switchgear covers, electrical enclosures, and even in LED lighting where the heat from lamps could pose a fire risk.

Safety Equipment: Fire-resistant visors, protective screens, and safety goggles made from PC provide both protection from physical impact and fire resistance in hazardous environments.

Industrial Use: PC sheets for machinery guards at places where the generation of spark or flame due to operation is highly expected, protect employees and apparatus without sacrificing the field of view. Case Studies and Practical Examples Railway Applications: Application of polycarbonate panels in Japanese bullet trains for their clarity and strength, which, on top of all other factors, meet fire safety requirements that are very high in public means of transportation.

- Marine Glazing: Boats and ships employ PC for their window glass, where the action of salt water together with fire might require the material to be resistant to both elements.

- Aerospace: Some grades of the polymer, as used in Lexan 9604 sheets, have been developed with the interior use of aircraft in mind. It would be fire-resistant but also must be lightweight and durable for flying safety concerns.

Challenges and Considerations

While polycarbonate offers an impressive array of benefits, consider:

• Cost: Fire-retardant additives add to the material cost, which could be a factor in large-scale applications.

• Recycling: The addition of flame retardants complicates the recycling process, although the development of newer technologies is making PC more environmentally sustainable.

• UV Stability: While PC is UV-stable, ensuring that fire-retardant formulations do not degrade under UV exposure remains critical, especially for outdoor applications.

Future Trends and Research

Current research continues to focus on the following issues: fire resistance improvement, new additives, and composite structures for making PC more fire-resistant while retaining other positive properties; ecological impact-development of flame retardants which would not compromise the possibility of recycling polycarbonate; smart materials-using of PC with integrated sensors or other technology for real-time fire detection systems or response mechanisms in buildings and vehicles. Conclusion

With intrinsic properties and advances in material science, polycarbonate sheets have carved a niche in fire-retardant applications. From saving lives in public buildings to ensuring the safety of passengers in different transport modes, the contribution of PC in fire safety is undeniable. As technology continues to evolve, we can only expect further innovative uses of this versatile material, further sealing its position as a cornerstone in fire protection strategies across industries.

By doing so, we have seen through this exploration how polycarbonate is not just a material but a critical component in modern safety engineering, offering protection where it's most needed, with the promise of continued innovation in fire safety.

Within 15-20 days after received payment...more