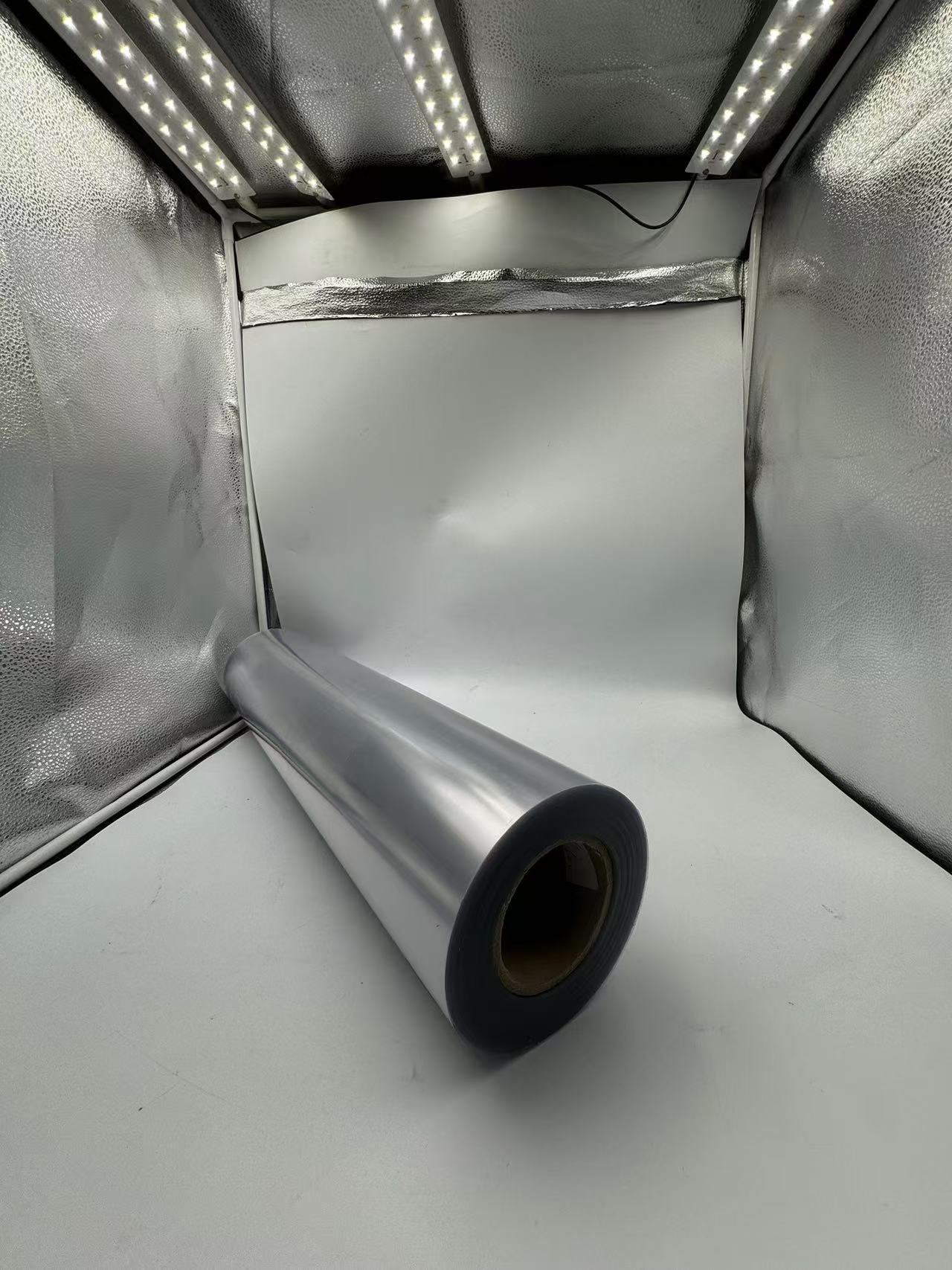

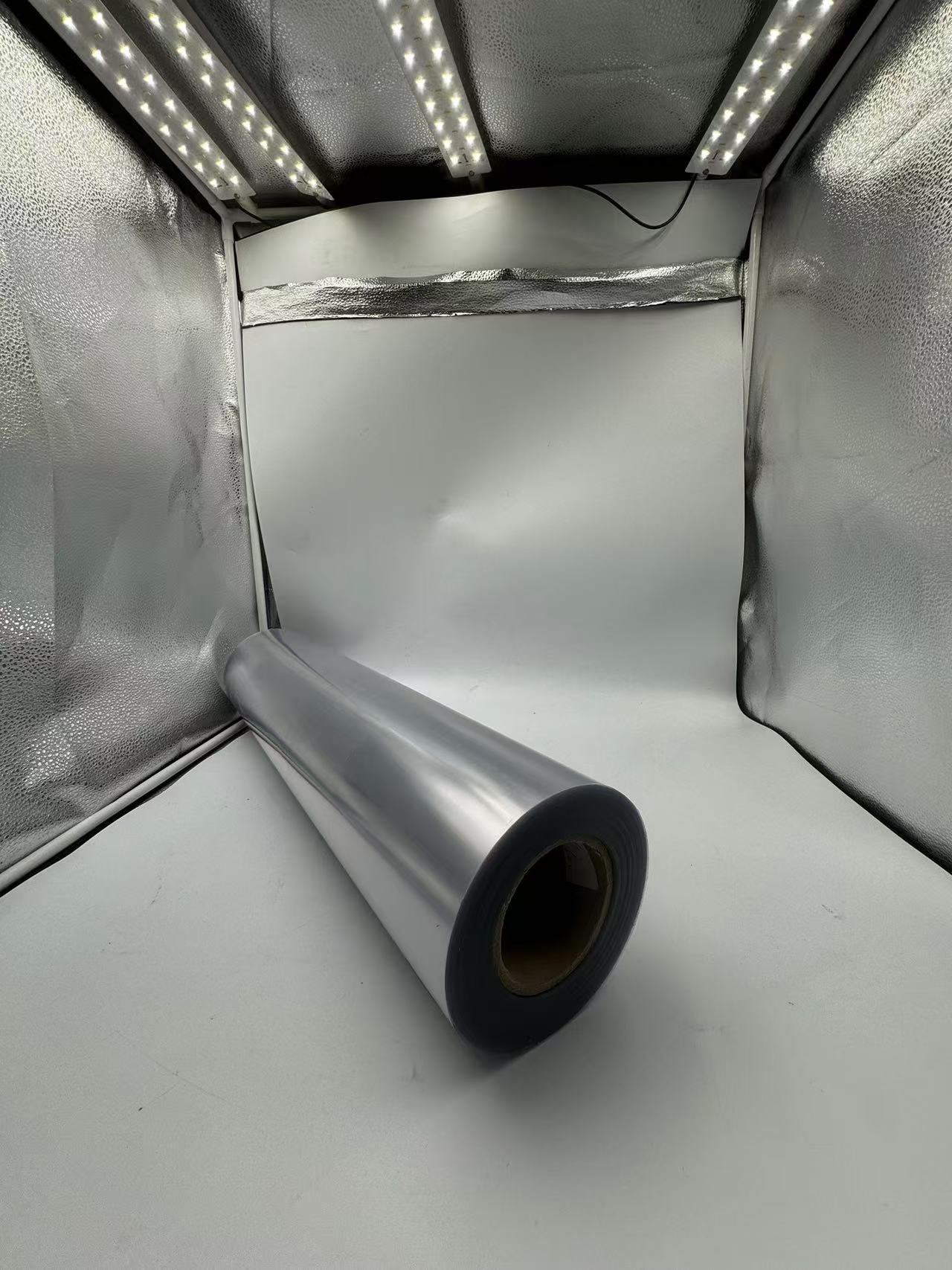

TL-PVC-0080 The Application of Transparent PVC Film as a Protective Layer in Steel Plate Composite Introduction

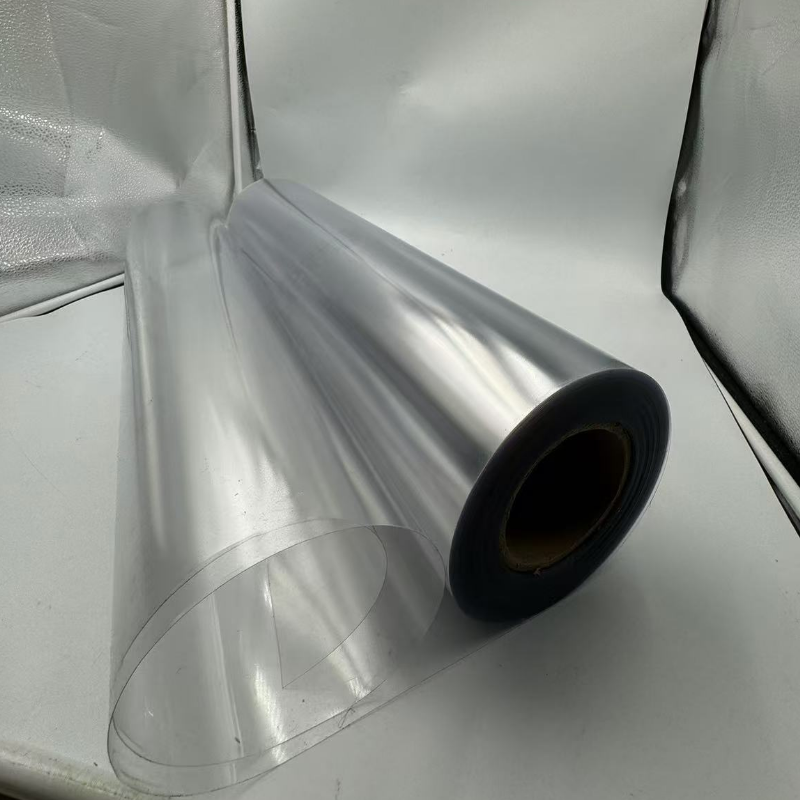

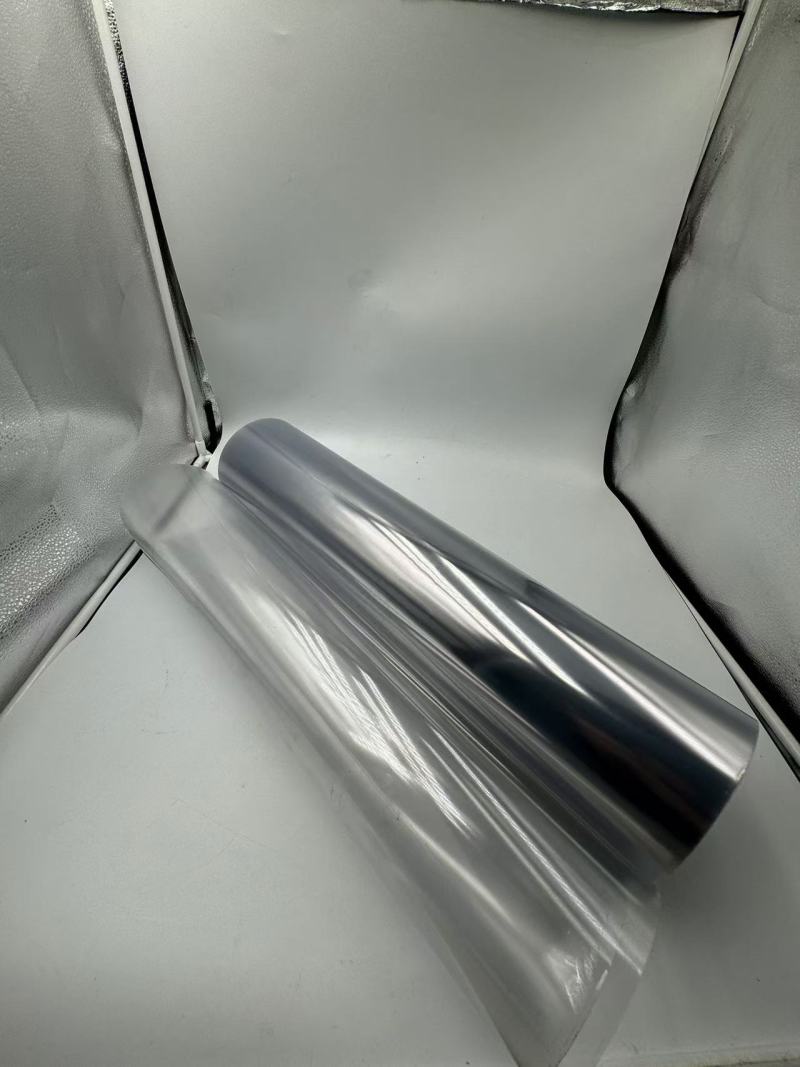

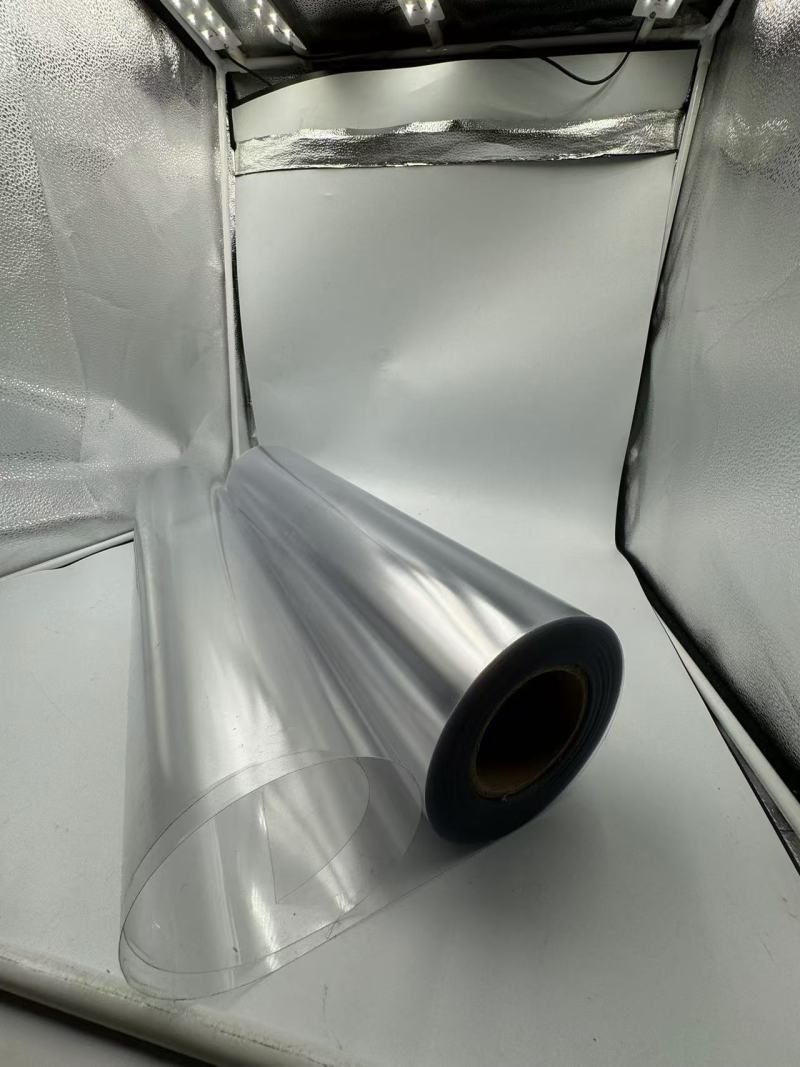

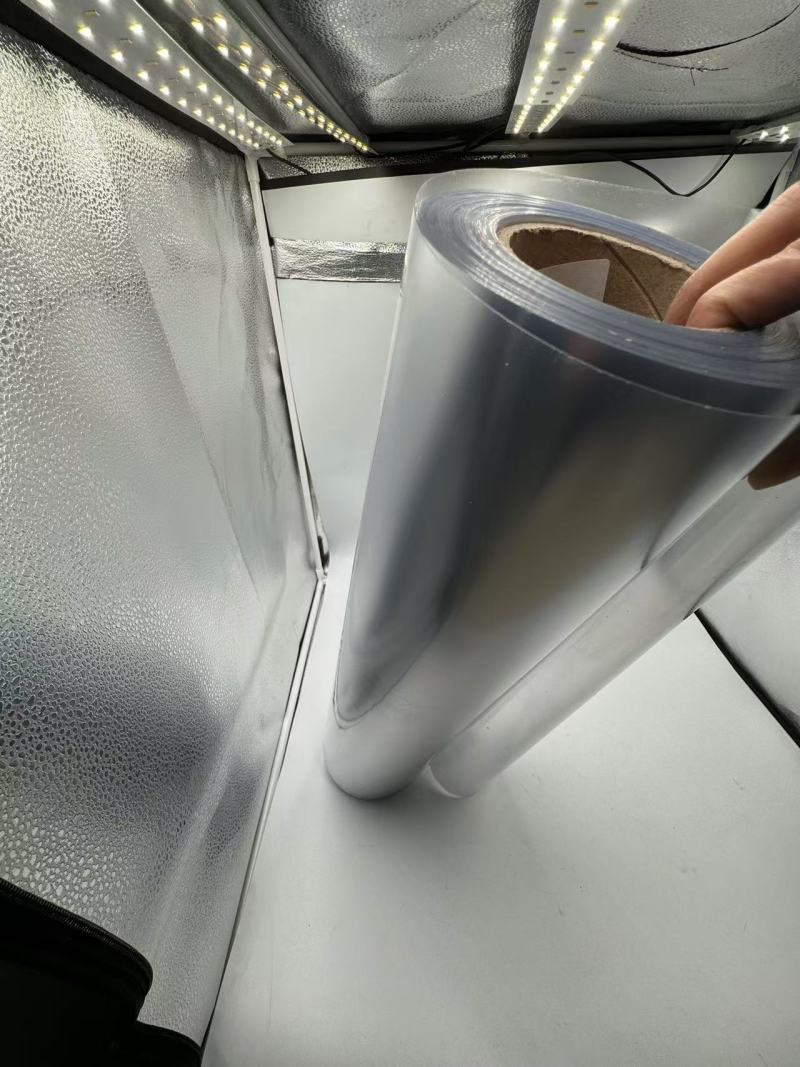

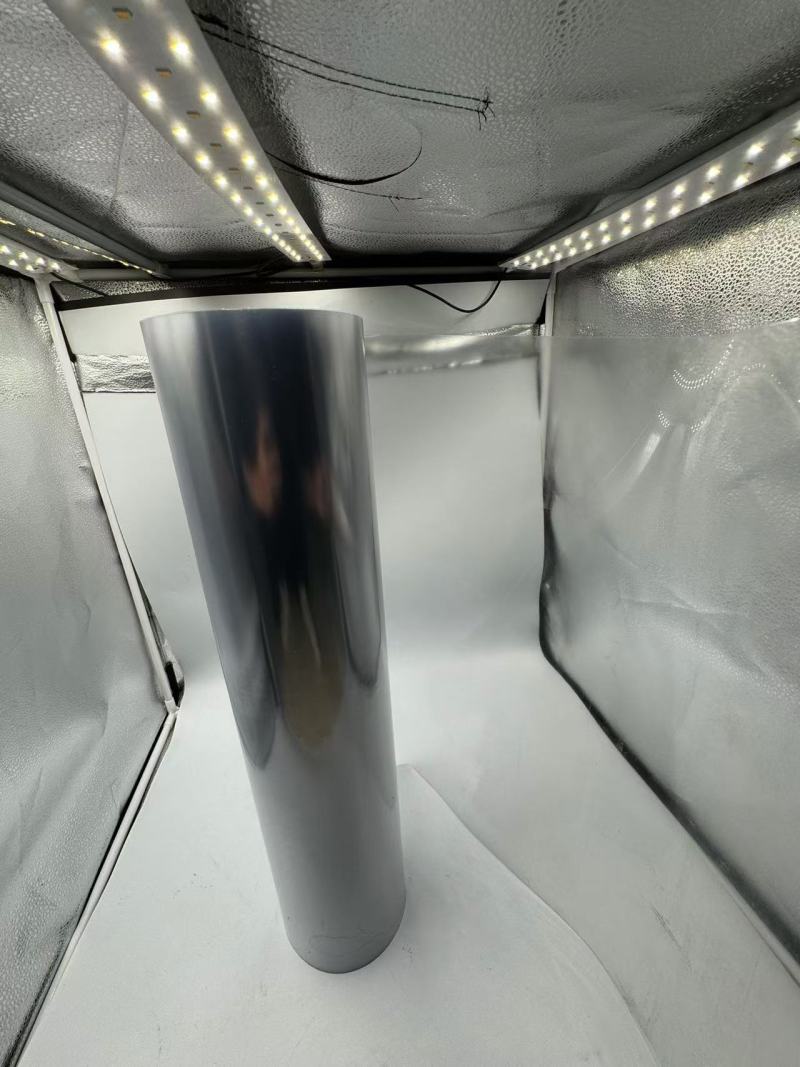

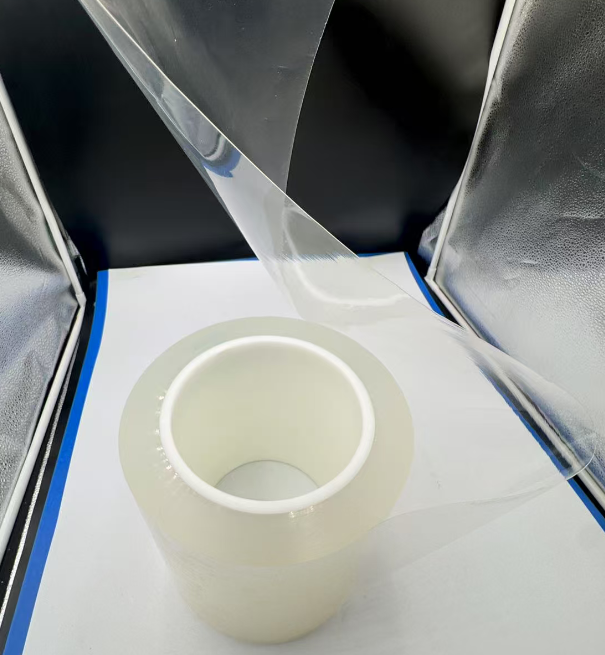

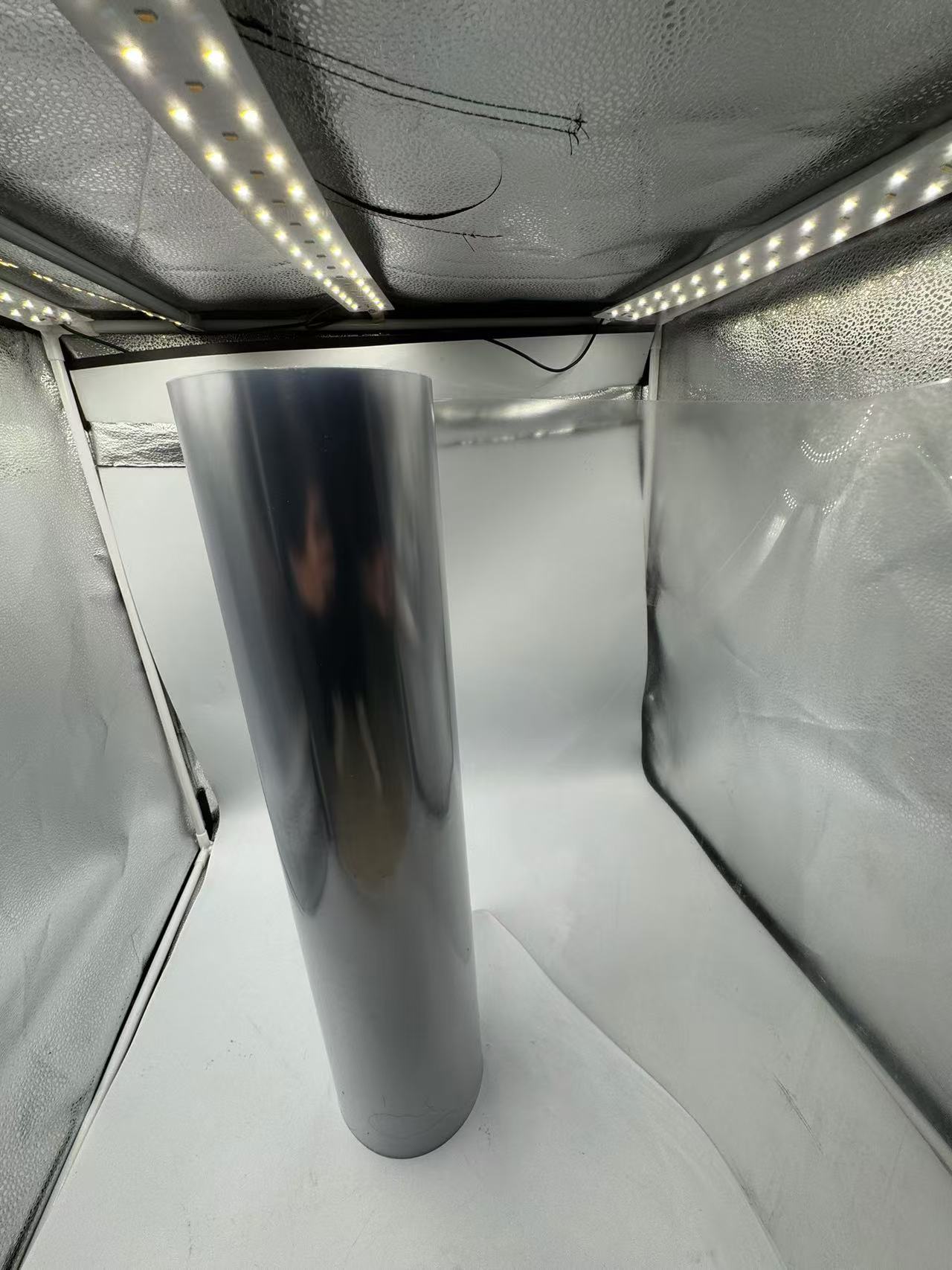

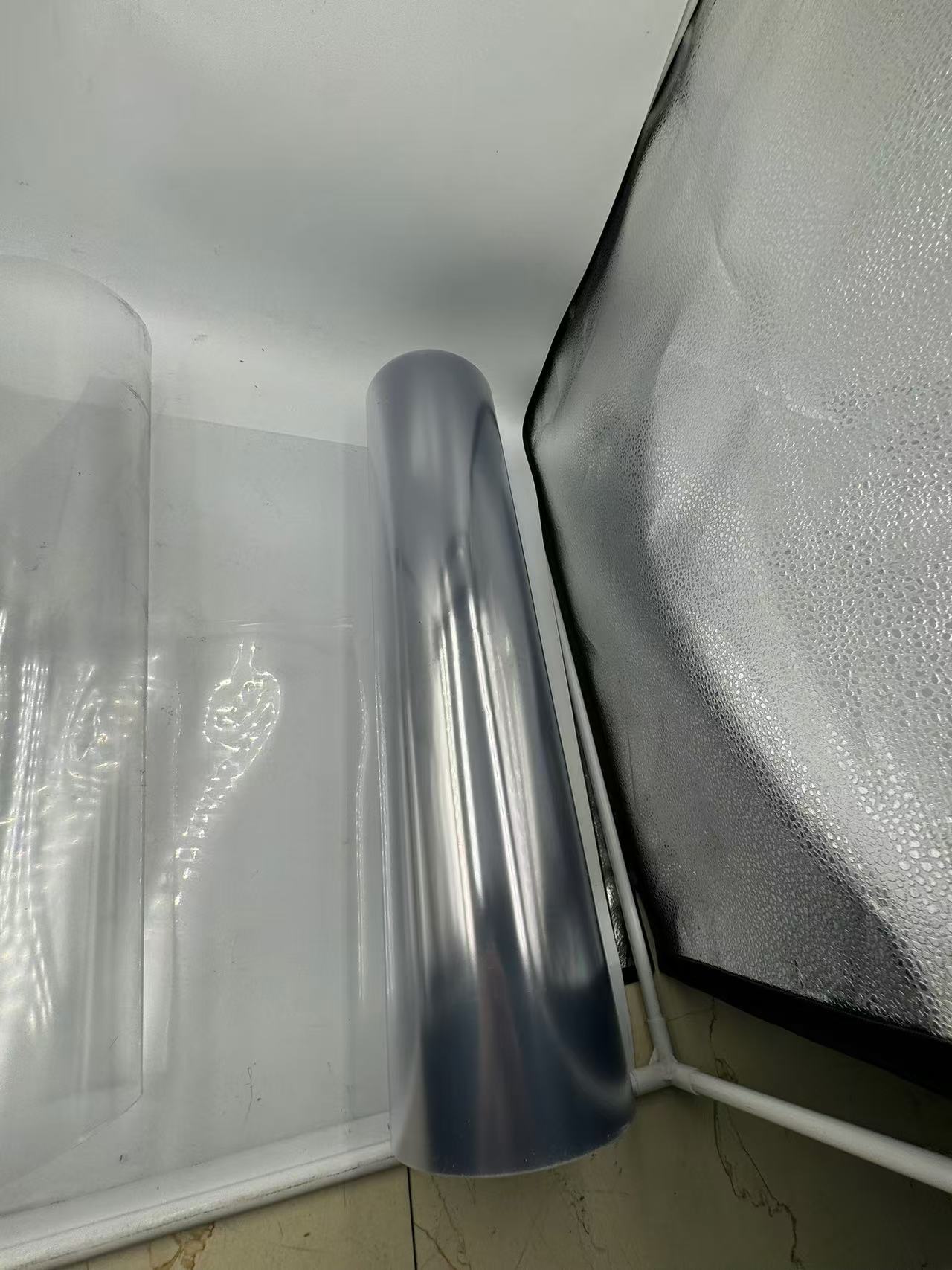

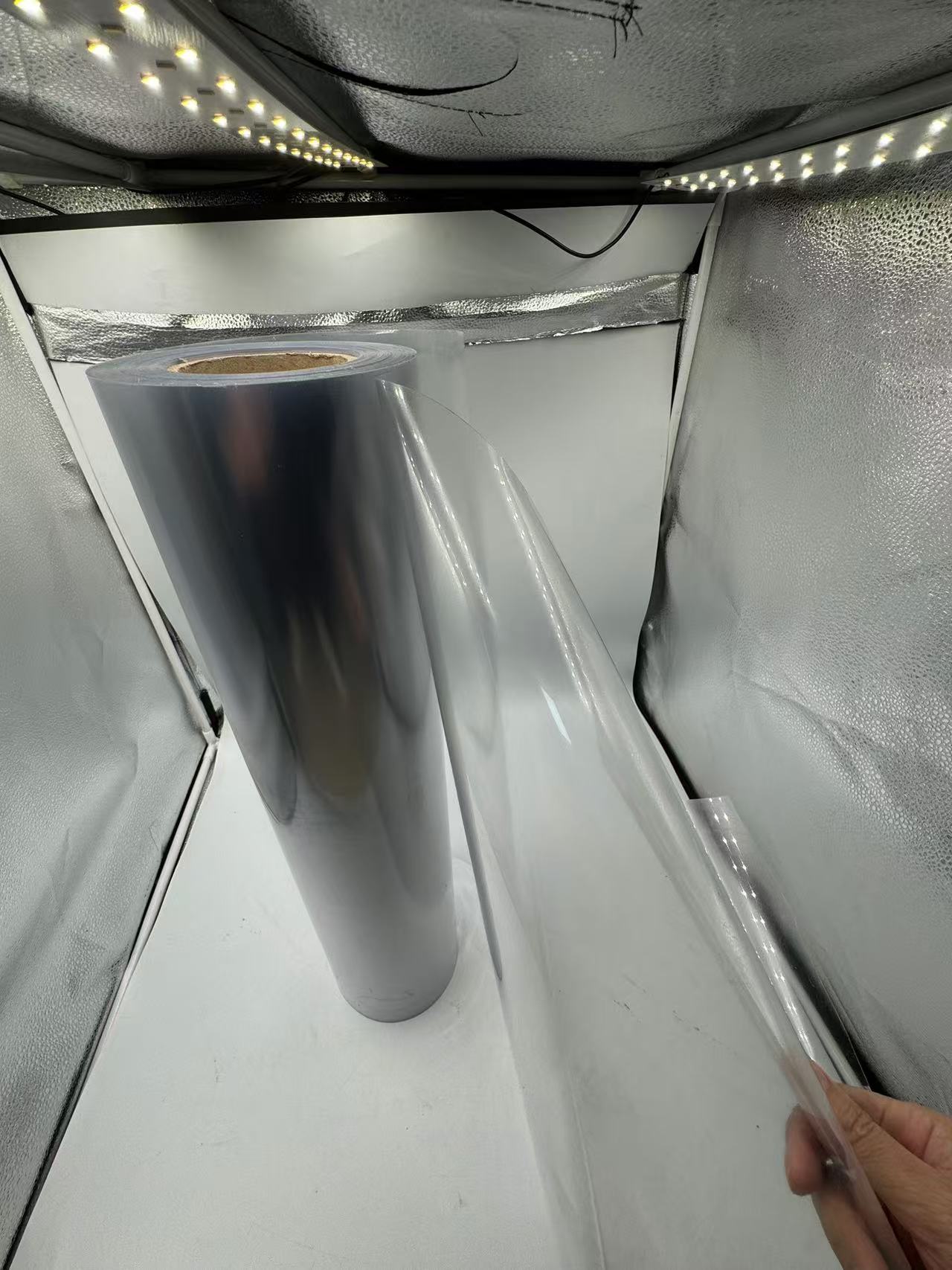

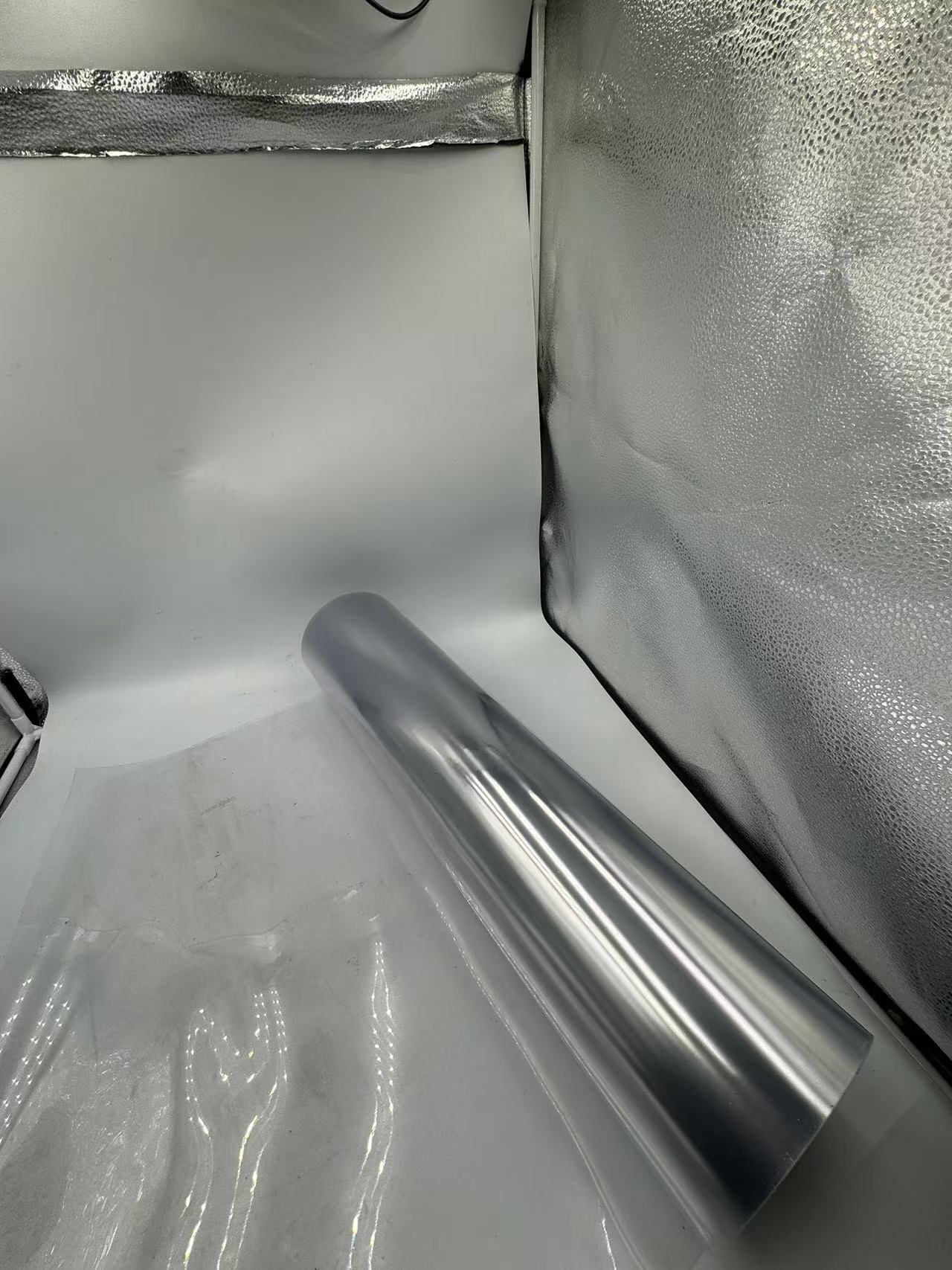

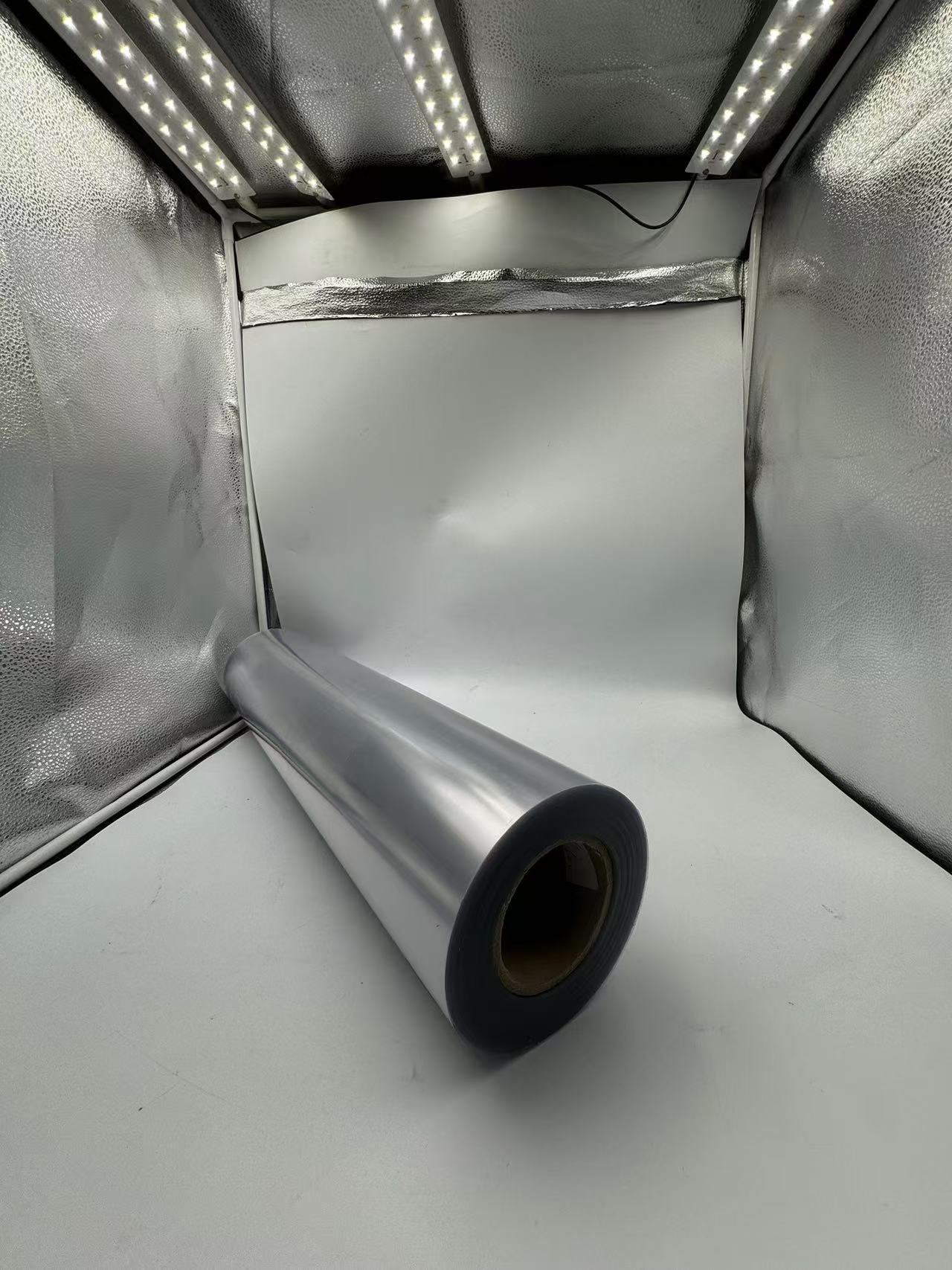

Material: PVC ROLL

Thickness 0.45-0.018mm-customization

Size: 80MM/1300MM/Customization

GRADE: Class A film

color: white/Transparent /customization

location: china

Usage: protection film

- TOPLEADER

- china

- 15WORKING DAYS

- 5000T/M

- Information

The Application of Transparent PVC Film as a Protective Layer in Steel Plate Composite

Introduction

In the field of material protection and composite structures, the use of transparent PVC (polyvinyl chloride) film as a protective layer for steel plates has gained significant attention. This remarkable application combines the unique properties of PVC film with the strength and durability of steel plates, creating a composite that offers enhanced performance and a wide range of benefits. This article will explore the in - depth details of using transparent PVC film in steel plate composite for protection purposes.

Properties of Transparent PVC Film

Chemical Composition and Structure

Transparent PVC film is primarily composed of vinyl chloride monomers polymerized to form long - chain molecules. The molecular structure of PVC contains carbon - chlorine bonds, which contribute to its characteristic properties. These bonds give the film a certain degree of stability and chemical resistance. The polymerization process can be carefully controlled to achieve the desired molecular weight and chain length, thereby influencing the physical and chemical properties of the final film.

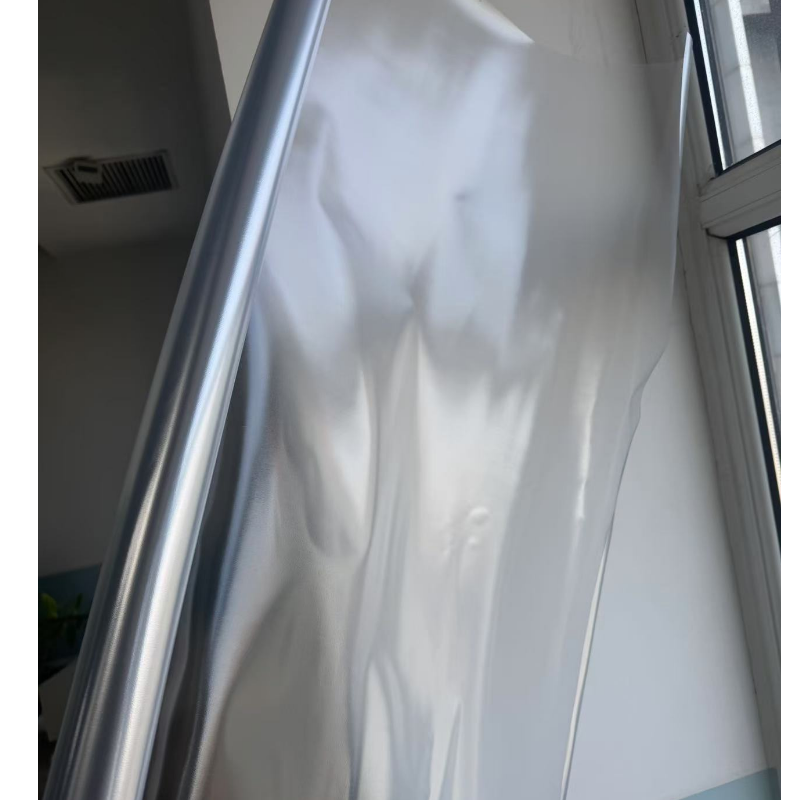

Transparency

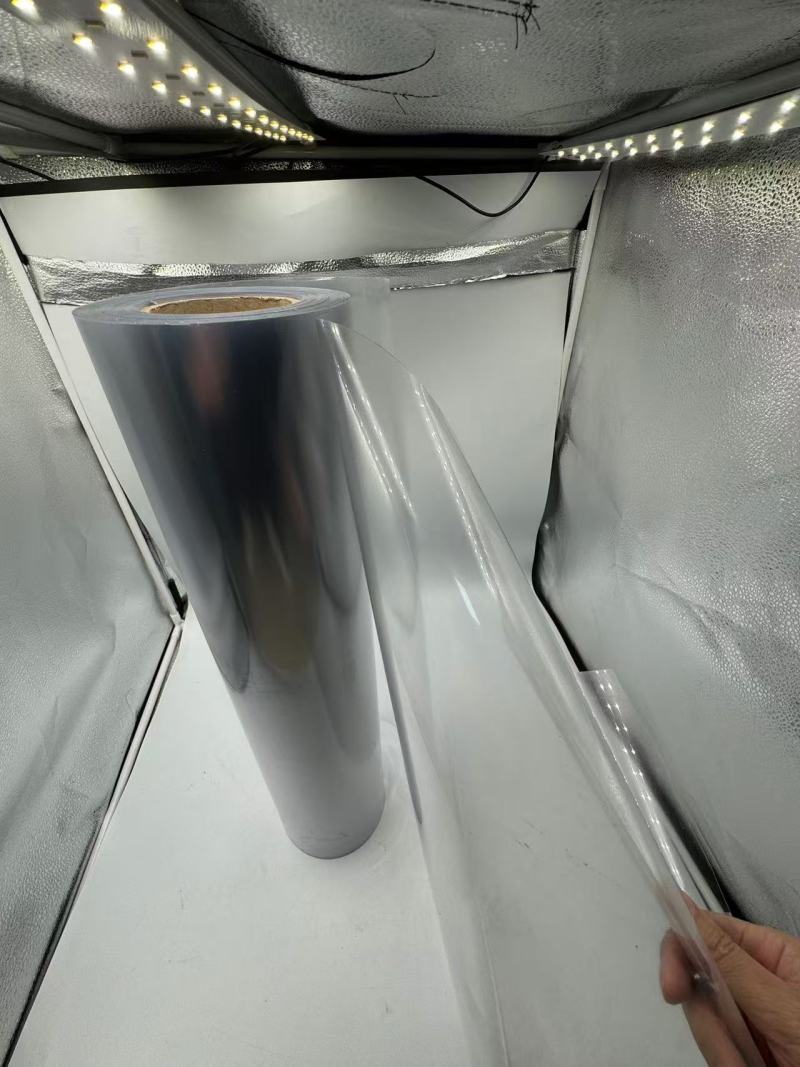

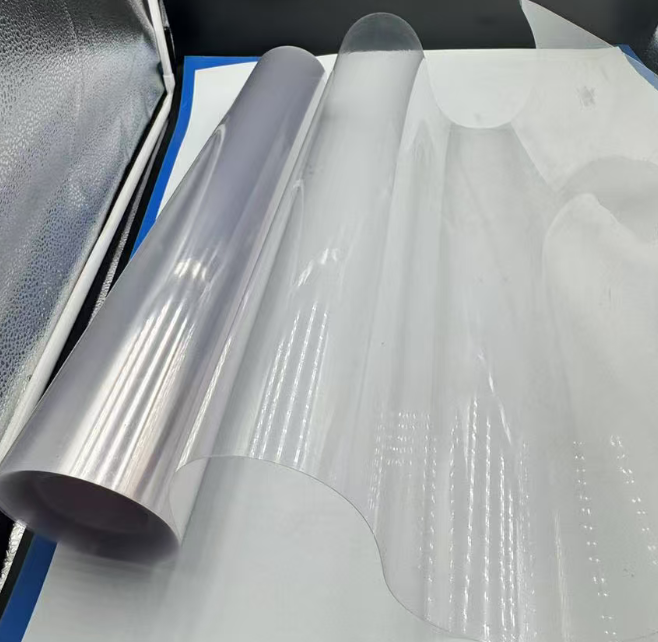

The transparency of PVC film is one of its most outstanding features. It allows for clear visibility through the film, which is of great significance in the context of steel plate protection. This transparency enables visual inspection of the steel surface without the need to remove the protective layer. It is achieved through advanced manufacturing techniques that ensure the purity of the PVC and the uniformity of its molecular structure. Special additives may be incorporated to further enhance the clarity of the film, allowing for an unobstructed view of the underlying steel plate.

Mechanical Properties

PVC film exhibits good mechanical strength despite its relatively thin nature. It has a notable tensile strength that enables it to withstand stretching forces during handling, installation, and use. This property is crucial as it ensures that the film remains intact and continues to provide protection to the steel plate. The film also possesses flexibility, which allows it to conform to the shape of the steel surface, even if it has curves or irregularities. Additionally, it has a certain level of puncture resistance, safeguarding it against accidental damage from sharp objects during various processes.

Barrier Properties

In terms of barrier capabilities, transparent PVC film plays a vital role in protecting the steel plate. It acts as an effective barrier against moisture, preventing water from reaching the steel surface. Moisture can cause significant problems such as rust and corrosion, and the PVC film's ability to block its ingress is essential. The film also offers some resistance to gases, reducing the penetration of oxygen and other potentially harmful gases that could react with the steel. This helps in maintaining the integrity and quality of the steel plate over time.

Chemical Resistance

PVC film is highly resistant to many common chemicals. It can withstand exposure to oils, greases, and various mild acids and alkalis. This chemical resistance is valuable in environments where the steel plate composite may come into contact with such substances. For instance, in industrial settings, the steel plate might be exposed to lubricants, cleaning agents, or other chemical substances, and the PVC film provides a protective shield against their potential corrosive effects.

Manufacturing Process of Transparent PVC Film for Steel Plate Protection

Raw Material Preparation

The production of transparent PVC film for steel plate protection commences with the careful selection of high - quality vinyl chloride monomer. The purity of the monomer is of utmost importance as it directly impacts the quality of the resulting film. Along with the monomer, a variety of additives are incorporated. These include plasticizers to enhance the flexibility of the film, stabilizers to improve its thermal stability and prevent degradation during processing and storage, and lubricants to facilitate the extrusion process. The proper selection and proportioning of these additives are based on the specific requirements of the film for steel plate protection applications.

Extrusion Process

Once the raw materials are prepared, they are thoroughly mixed and fed into an extruder. The extruder heats the mixture to a molten state under precisely controlled temperature and pressure conditions. The temperature profile within the extruder is adjusted to ensure uniform melting of the PVC resin and proper dispersion of the additives. The molten PVC is then forced through a die to form a continuous sheet of film. The design of the die and the extrusion speed are carefully calibrated to achieve the desired thickness and width of the film. During the extrusion process, the molten film also undergoes cooling and calibration systems to maintain its uniformity and dimensional stability.

Calendering or Casting (Optional)

In some manufacturing scenarios, the extruded PVC film may undergo either calendering or casting processes. Calendering involves passing the film through a series of rollers to further refine its thickness, smoothness, and surface quality. This process can enhance the mechanical properties and appearance of the film. Casting, on the other hand, is a method where the molten PVC is spread onto a moving belt or drum to form the film. This technique can be utilized to achieve specific surface textures or to incorporate additional layers or coatings during the film - forming process.

Quality Control and Finishing

After the film is formed, it undergoes rigorous quality control procedures. The thickness of the film is measured using highly accurate instruments to ensure it meets the specified requirements. The transparency, mechanical strength, and barrier properties are also thoroughly tested. Any defects or non - conformities are identified and corrected. The film may then be wound onto rolls for storage or further processing. In some cases, additional finishing operations such as surface treatment to improve printability or the application of anti - static coatings may be carried out to enhance the film's functionality in steel plate protection applications.

The Process of Applying Transparent PVC Film to Steel Plate as a Protective Layer

Surface Preparation of Steel Plate

Before applying the transparent PVC film, the steel plate surface must be properly prepared. This involves a series of cleaning procedures to remove any dirt, grease, rust, or other contaminants. Mechanical cleaning methods, such as sandblasting or wire brushing, can be used to remove loose rust and scale. Chemical cleaning with solvents or detergents may also be employed to eliminate grease and other stubborn contaminants. The goal is to achieve a clean, smooth, and chemically active surface that will ensure good adhesion between the steel and the PVC film. In some cases, surface treatment processes like etching or applying a primer may be necessary to further enhance the bonding strength.

Application of Adhesive (if required)

Depending on the specific application and the nature of the steel plate and PVC film combination, an adhesive may be used to bond the film to the steel surface. The choice of adhesive is critical as it must have excellent adhesion to both the PVC film and the steel plate. There are various types of adhesives available, including solvent - based adhesives, water - based adhesives, and hot - melt adhesives. The adhesive is usually applied evenly onto either the steel plate or the PVC film, following the manufacturer's instructions. In some cases, the adhesive may require curing or drying under specific conditions, such as a certain temperature or humidity level, to achieve maximum bonding strength.

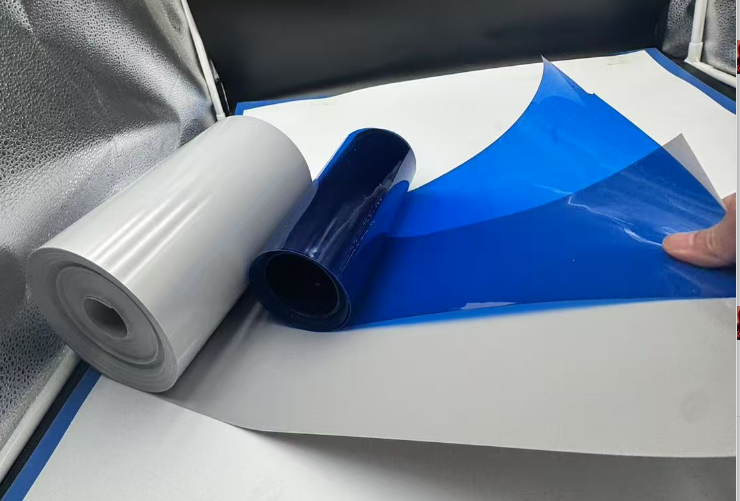

Lamination Process

The lamination of the transparent PVC film onto the steel plate can be achieved through different methods. One common approach is to use a laminating machine. The prepared steel plate and the PVC film are fed into the laminating machine, which applies pressure and, in some cases, heat to ensure proper bonding. The pressure and temperature conditions are carefully controlled to prevent any damage to the film or the steel plate. Another method is to use a manual lamination process, especially for smaller or custom - sized composite panels. In this case, rollers or other tools are used to apply even pressure to the film and the steel plate to achieve good adhesion.

Post - lamination Treatment

After the lamination process, the composite structure may undergo further treatment. This can include trimming the edges to achieve the desired final size and shape. In some applications, additional protective coatings may be applied to the PVC film surface to enhance its durability or provide specific functions such as anti - scratch or anti - UV properties. Quality control checks are also conducted during this stage to ensure that the PVC film is properly bonded to the steel plate and that there are no air bubbles, wrinkles, or other defects in the composite structure.

Advantages of Using Transparent PVC Film as a Protective Layer for Steel Plate

Visual Inspection and Monitoring

The transparency of the PVC film allows for easy visual inspection of the steel plate. This is extremely beneficial during the manufacturing process, as it enables the detection of any surface defects, scratches, or other issues on the steel surface. Even after the composite is completed and in use, the transparency enables continuous monitoring of the steel plate's condition. For example, in applications where the steel plate may be subject to corrosion or other forms of degradation, the ability to see through the film allows for early detection and timely maintenance. This can significantly extend the lifespan of the composite structure and reduce the risk of unexpected failures.

Protection Against Corrosion

As previously mentioned, the PVC film acts as a barrier against moisture and other environmental factors that can cause corrosion of the steel plate. By preventing water and oxygen from reaching the steel surface, the film helps to maintain the integrity of the steel. This is particularly important in outdoor applications or in environments with high humidity or exposure to chemicals. The corrosion - protecting ability of the PVC film can reduce the need for frequent painting or other anti - corrosion treatments of the steel plate, saving both time and resources.

Aesthetic Enhancement

The clear and smooth appearance of the transparent PVC film can enhance the aesthetic value of the steel plate composite. In applications where the appearance of the structure matters, such as in architectural or decorative uses, the film can give the steel a polished and refined look. It can also be used to create unique visual effects by applying patterns or designs onto the film surface. This allows for greater creativity in design and can make the composite structure more visually appealing.

Improved Handling and Installation

The PVC film provides a protective layer on the steel plate, which makes it easier to handle during transportation and installation. The film reduces the risk of scratching or damaging the steel surface during these processes. Additionally, the flexibility of the film allows the composite structure to be more easily shaped or bent during installation, especially in applications where the steel plate needs to conform to specific architectural or engineering requirements. This can simplify the installation process and reduce the potential for errors.

Cost - effectiveness

Using transparent PVC film as a protective layer in steel plate composite can be a cost - effective solution. The film itself is relatively inexpensive compared to some alternative protective materials. The reduced need for frequent maintenance and anti - corrosion treatments due to the film's protective properties can also lead to long - term cost savings. Furthermore, the ease of installation and handling can lower labor costs during the construction or manufacturing process.

Applications of Transparent PVC Film - Steel Plate Composite Protective Layer

Architectural Applications

Facades and Cladding

In modern architecture, the use of steel plate composite with transparent PVC film for facades and cladding has become increasingly popular. The transparency of the film allows natural light to penetrate while protecting the steel from the elements. The aesthetic appeal of the film can be exploited to create unique and visually striking facades. For example, in a commercial building, the steel plate composite with PVC film can be designed with different patterns or colors to match the overall design concept. The corrosion - protection property of the film ensures the long - term durability of the facade, even in harsh urban environments.

Interior Design Elements

Transparent PVC film - steel plate composites are also used in interior design. They can be used to create partitions, wall panels, or decorative elements. The clear film allows for an open and airy feel in interior spaces while providing the strength and durability of the steel. In a restaurant or a hotel lobby, for example, the composite can be used to create a modern and stylish partition that divides different areas while still maintaining a sense of transparency.

Industrial Applications

Machine Enclosures

In industrial settings, machine enclosures made from steel plate composite with transparent PVC film are widely used. The transparency of the film allows operators to see the internal components of the machine while it is in operation, which is crucial for monitoring and maintenance. The film's protection against dust, moisture, and other contaminants helps to keep the machine in good working condition. The mechanical strength of the steel plate and the flexibility of the PVC film make the enclosure durable and able to withstand the rigors of the industrial environment.

Storage Tanks and Containers

For storage tanks and containers in industries such as chemical, food, and beverage, the combination of steel plate and transparent PVC film can be advantageous. The PVC film can act as a protective inner lining, preventing the contents of the tank from coming into direct contact with the steel. This is especially important when storing corrosive or sensitive substances. The transparency of the film allows for visual inspection of the tank's interior, facilitating inventory management and detecting any potential leaks or issues.

Transportation Applications

Vehicle Body Panels

In the transportation industry, transparent PVC film - steel plate composites can be used for vehicle body panels. The film provides protection against environmental factors such as rain, snow, and UV radiation, while the steel plate provides the necessary strength. The transparency of the film can be used to create unique design features on the vehicle, such as see - through sections or decorative elements. In addition, the composite structure can be more lightweight compared to traditional materials, contributing to improved fuel efficiency.

Shipping Containers

Shipping containers often face harsh marine environments during transportation. The use of steel plate composite with transparent PVC film can help protect the steel from corrosion caused by saltwater and moisture. The transparency of the film allows for easy identification of the contents of the container during loading and unloading. The composite structure also provides the required strength to withstand the rigors of shipping, including stacking and rough handling.

Case Studies of Transparent PVC Film - Steel Plate Composite Protective Layer in Practice

Case Study 1: Architectural Facade of a High - Rise Building

A high - rise commercial building in a coastal city opted for a steel plate composite with transparent PVC film for its facade. The PVC film was chosen for its transparency, which allowed natural light to enter the building while reducing heat gain. The film also protected the steel from the corrosive effects of saltwater and high humidity in the coastal environment. During the construction process, the transparency of the film enabled easy inspection of the steel surface for any installation - related defects. After completion, the facade not only provided an aesthetically pleasing look but also required minimal maintenance over the years. The building's energy consumption was also reduced due to the light - filtering properties of the PVC film.

Case Study 2: Industrial Machine Enclosure in a Manufacturing Plant

A manufacturing plant installed machine enclosures made from steel plate composite with transparent PVC film to protect their production equipment. The transparency of the film allowed operators to monitor the machine's operation without having to open the enclosure frequently. This reduced the risk of accidental contact with moving parts and improved overall safety. The PVC film protected the machines from dust and oil splatters, and the steel plate provided the necessary structural support. The composite enclosures were easy to install and had a long lifespan, reducing the need for frequent replacements and maintenance.

Case Study 3: Shipping Containers for Perishable Goods

A shipping company started using steel plate composite with transparent PVC film for their containers transporting perishable goods. The PVC film's transparency allowed for quick identification of the contents during loading and unloading, reducing the time spent on inventory checks. The film also protected the steel from corrosion during the long - sea voyages. The composite containers maintained a stable internal environment for the perishable goods, reducing spoilage rates. The use of the composite structure improved the overall efficiency of the shipping process and reduced costs associated with damaged goods.

Challenges and Solutions in Using Transparent PVC Film in Steel Plate Composite Protective Layer

Adhesion Problems

One of the main challenges in combining transparent PVC film with steel plate is ensuring proper adhesion. Poor adhesion can lead to delamination of the film, which can compromise the performance of the composite structure. To address this issue, it is essential to select the right adhesive based on the specific properties of the PVC film and the steel surface. Surface preparation of the steel plate is also crucial, as any contaminants can affect the bonding strength. In some cases, additional surface treatments such as priming or using adhesion - promoting agents can be applied to improve the adhesion.

Temperature and Environmental Sensitivity

PVC film may be sensitive to temperature changes and certain environmental conditions. In extreme cold or hot environments, the film may become brittle or lose its flexibility, respectively. To overcome this, special grades of PVC film with improved temperature stability can be used. In addition, protective coatings or laminates can be applied to the film to enhance its resistance to environmental factors. For example, an anti - UV coating can be added to protect the film from degradation caused by sunlight in outdoor applications.

Recycling and Disposal

At the end of its life cycle, the composite structure of steel plate and PVC film needs to be disposed of properly. Recycling both materials can be challenging due to the bonding between them. However, research is being conducted to develop effective recycling methods. One approach is to find ways to separate the PVC film from the steel plate, either through mechanical or chemical means. Another solution is to design the composite in such a way that it is more easily recyclable, such as using removable adhesives or designing for disassembly.

Conclusion

The use of transparent PVC film as a protective layer in steel plate composite has opened up a world of possibilities in various industries. Its unique properties, including transparency, mechanical strength, barrier protection, and chemical resistance, make it an ideal material for enhancing the performance and functionality of steel plates. The composite process, from film manufacturing to lamination with the steel plate, has been refined over the years to ensure high - quality results. Despite the challenges related to adhesion, environmental sensitivity, and recycling, continuous efforts are being made to overcome these issues. With its numerous advantages and diverse applications, the transparent PVC film - steel plate composite protective layer is set to continue playing a significant role in architecture, industry, and transportation, providing durable, aesthetically pleasing, and cost - effective solutions for a wide range of projects.

Within 15-20 days after received payment...more