The Properties of PET Film and Its Application in Blister Packaging for Tableware

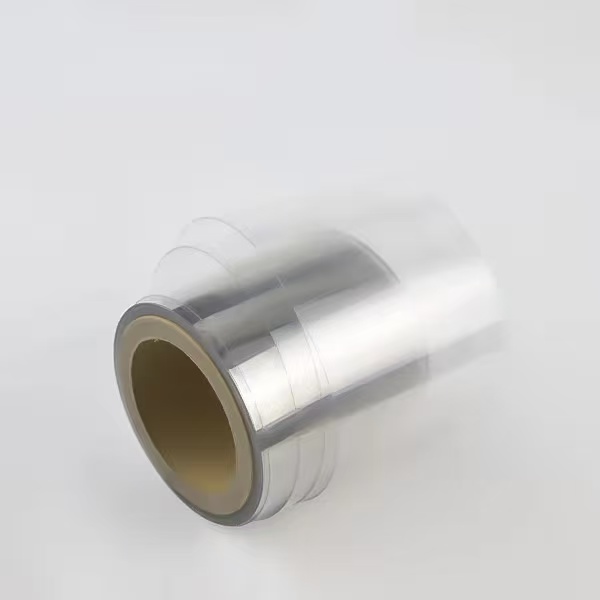

NamePET Plastic film roll

SizeTk:0.1-0.9mm, h100-1200mm

MaterialPET/PP/Customized

Color/printingTransparent/customized

PackagingCartons/customized

OEM/ODMAccepeted

MOQ1000KG

UsageVegetable/Fruit/Meat

FeatureHigh durability, eco-friendly, compression resistance

AdvantageCompetitive price, consistent quality, 24 hours online service

- TOPLEADER

- CHINA

- 15 WORKINGDAYS

- 5000T/M

- Information

- Video

- Download

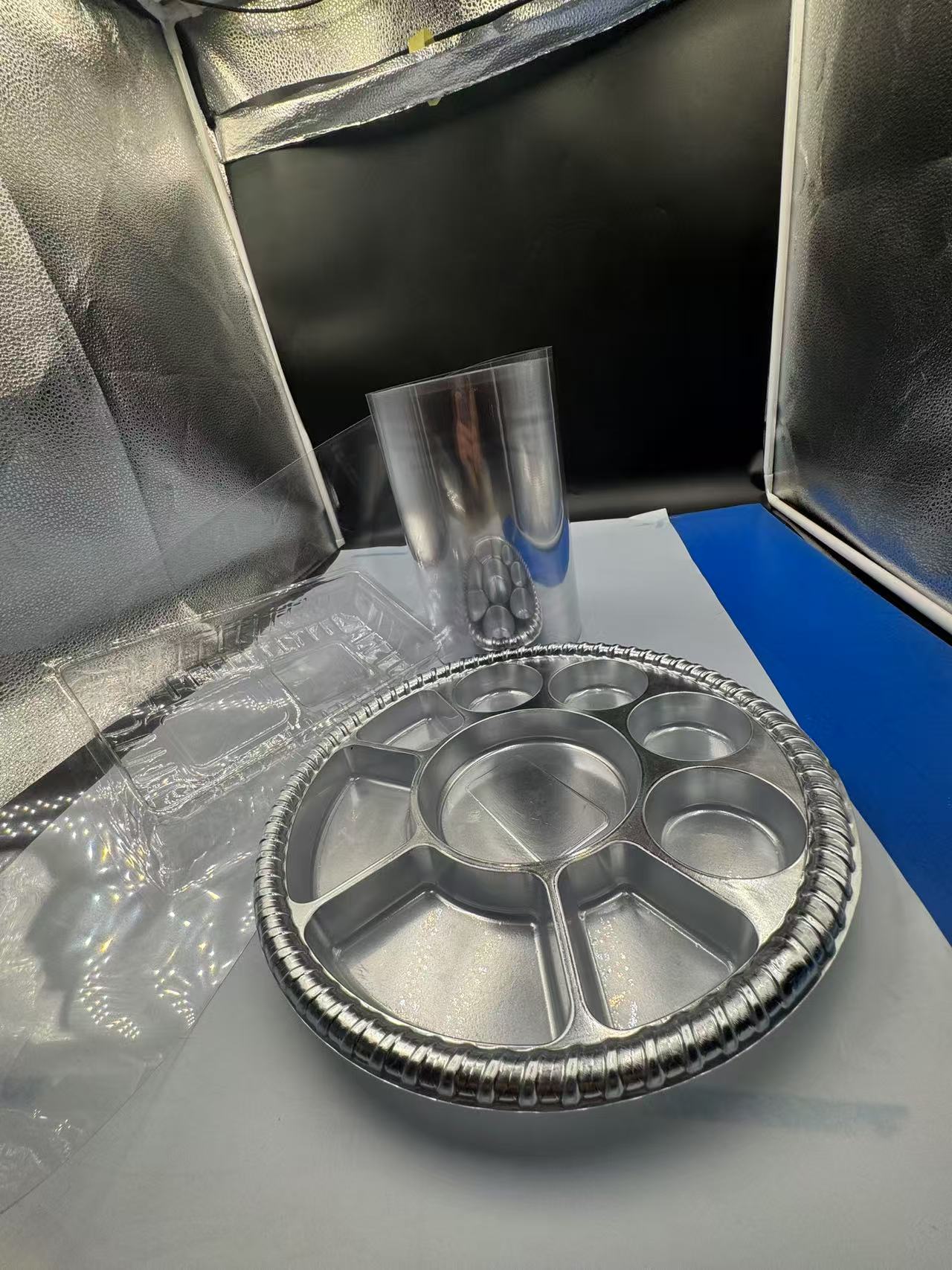

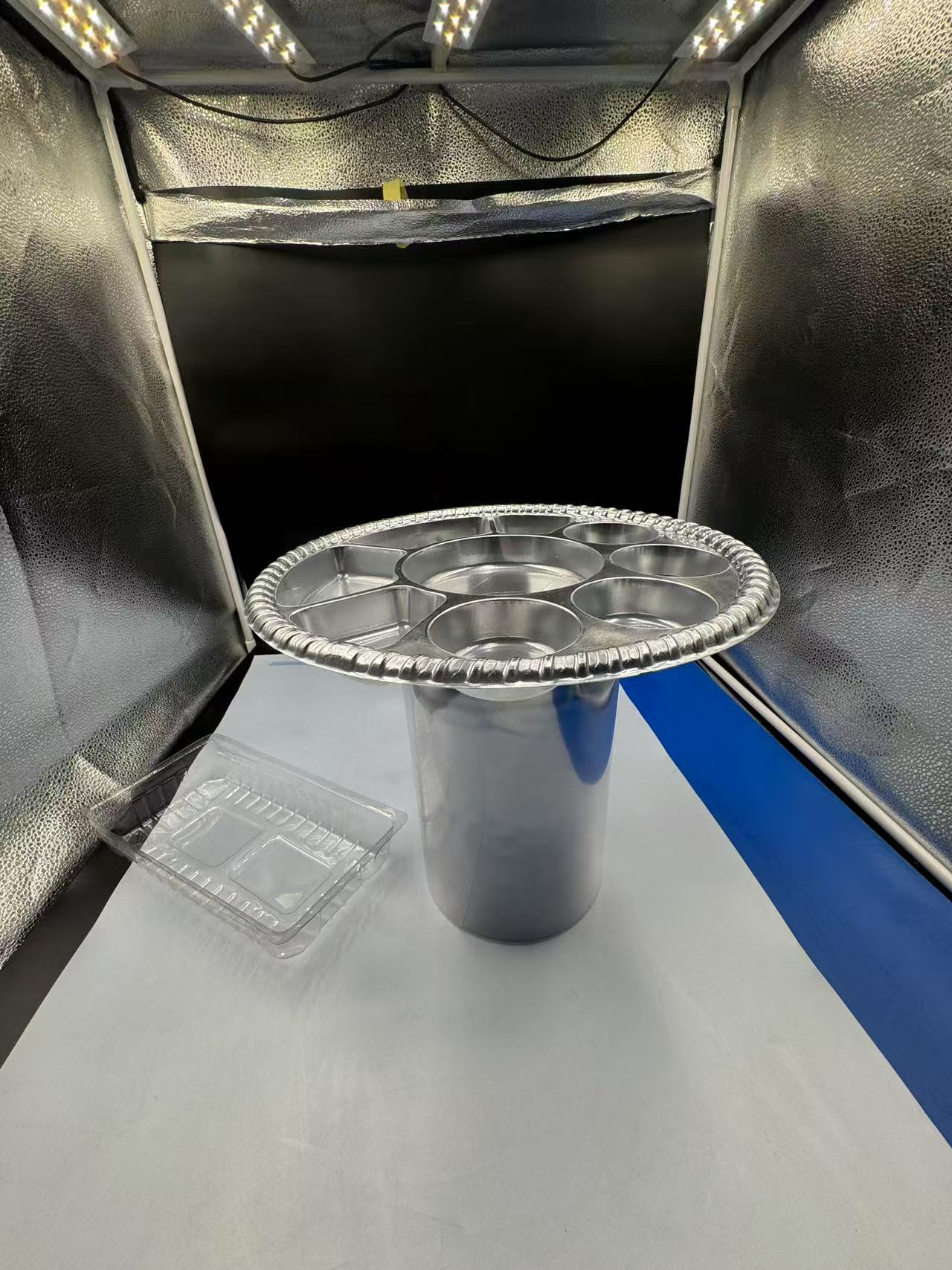

Polyethylene Terephthalate (PET) film is a widely recognized material in the packaging industry, celebrated for its remarkable combination of physical, chemical, and mechanical properties. As a thermoplastic polymer, PET film has become a staple in various applications, particularly in blister packaging for tableware.  This article explores the intrinsic characteristics of PET film and delves into how these attributes make it an ideal choice for protecting and presenting disposable or reusable tableware, such as spoons, forks, knives, and trays. Through a detailed examination of its features and practical uses, we aim to highlight why PET film stands out in the competitive world of packaging materials.

This article explores the intrinsic characteristics of PET film and delves into how these attributes make it an ideal choice for protecting and presenting disposable or reusable tableware, such as spoons, forks, knives, and trays. Through a detailed examination of its features and practical uses, we aim to highlight why PET film stands out in the competitive world of packaging materials.

Key Properties of PET Film

PET film boasts a unique set of properties that distinguish it from other plastic films like PVC or PP (polypropylene). These characteristics not only ensure functionality but also enhance the aesthetic and environmental appeal of the final product.

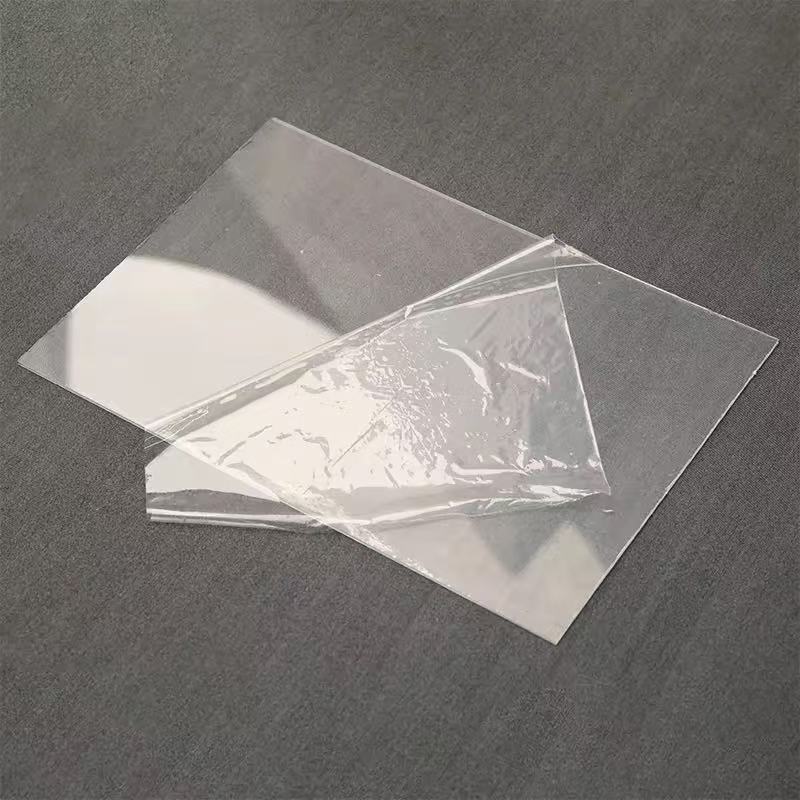

Clarity and Transparency

One of the standout features of PET film is its exceptional clarity. With a high light transmission rate, PET film offers a crystal-clear appearance that rivals glass. This transparency is crucial in blister packaging for tableware, as it allows consumers to visually inspect the product before purchase. For instance, a set of elegantly designed cutlery encased in PET film appears pristine and inviting, boosting consumer confidence in the product’s quality.

Mechanical Strength and Durability

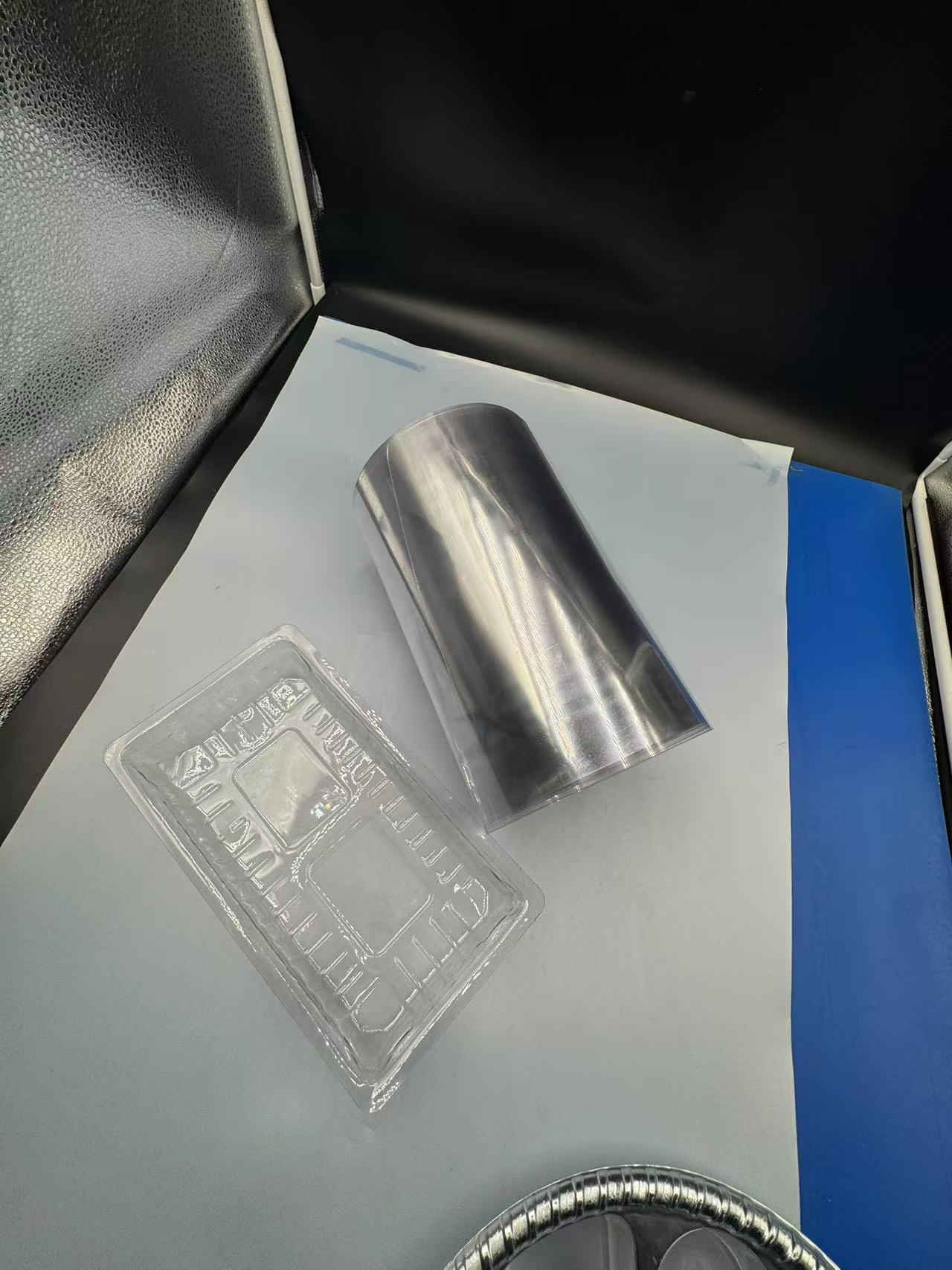

PET film exhibits impressive tensile strength and resistance to impact, making it highly durable. This is particularly advantageous in packaging tableware, where the film must withstand handling, stacking, and transportation without cracking or deforming. Imagine a stack of plastic forks packaged in PET film blister packs being shipped across continents—its robustness ensures that the contents remain intact, even under pressure.

Thermal Stability

With a melting point around 250°C and good resistance to temperature fluctuations, PET film maintains its structural integrity during processing and use. In blister packaging, this thermal stability is vital during the thermoforming process, where the film is heated and molded into precise shapes to encase tableware. The ability to endure heat without losing clarity or strength ensures a consistent and reliable packaging outcome.

Chemical Resistance

PET film is resistant to a wide range of chemicals, including oils, greases, and mild acids. This property is especially beneficial for tableware packaging, as it protects the contents from contamination by external substances during storage or display. For example, if a packaged spoon comes into contact with a greasy surface, the PET film acts as a barrier, preserving the hygiene of the item inside.

Recyclability and Sustainability

In an era where environmental concerns are paramount, PET film shines as a recyclable material. It can be reprocessed into new products, reducing waste and supporting a circular economy. Many manufacturers now produce PET film with a percentage of recycled content, aligning with consumer demand for sustainable packaging solutions. For tableware, this means that a disposable fork’s packaging can have a second life, minimizing its environmental footprint.

Within 15-20 days after received payment...more