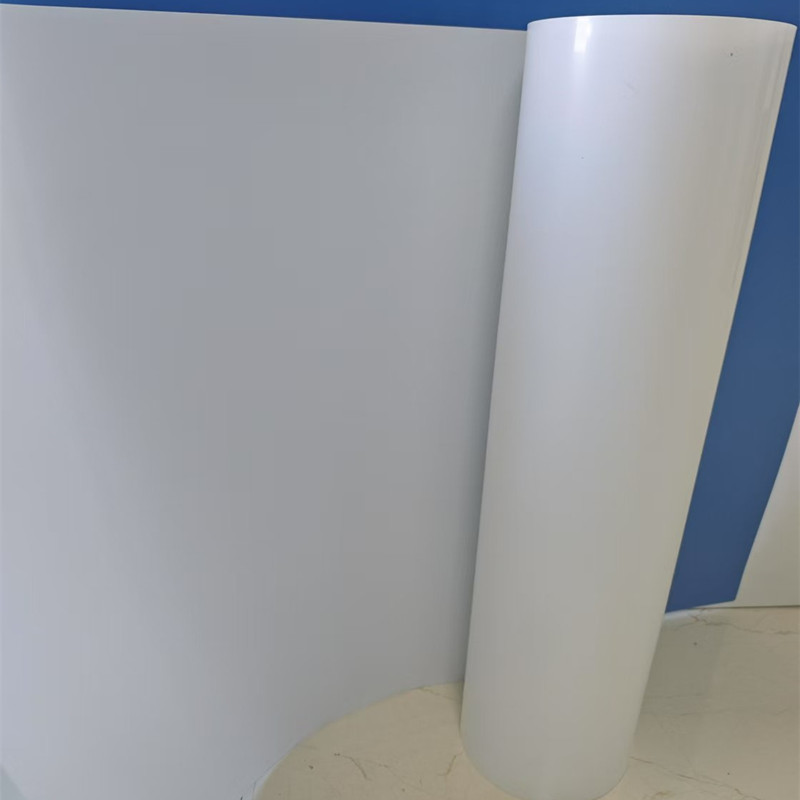

White PS (Polystyrene) Thermoforming Sheet

Available in food-contact-approved grades: Meets global food safety standards, including FDA 21 CFR Part 177.1640 (U.S.), EU Regulation (EC) No. 10/2011, and China GB 4806.6—safe for direct contact with dry, aqueous, and fatty foods.

- TOP LEADER

- CHINA

- 7-15 Working days

- 5000t/Month

- Information

Exceptional heat stability: Maintains consistent shape during heating (optimal thermoforming temperature range: 120°C - 160°C) and cools quickly for fast production cycles—reducing manufacturing time and costs.

Excellent drapeability: Conforms seamlessly to complex mold shapes (e.g., deep cavities, intricate details) without cracking, wrinkling, or thinning, ensuring uniform wall thickness across finished parts.

Compatible with all standard thermoforming methods: Vacuum forming, pressure forming, twin-sheet forming, and drape forming—suitable for low-to-high volume production runs.

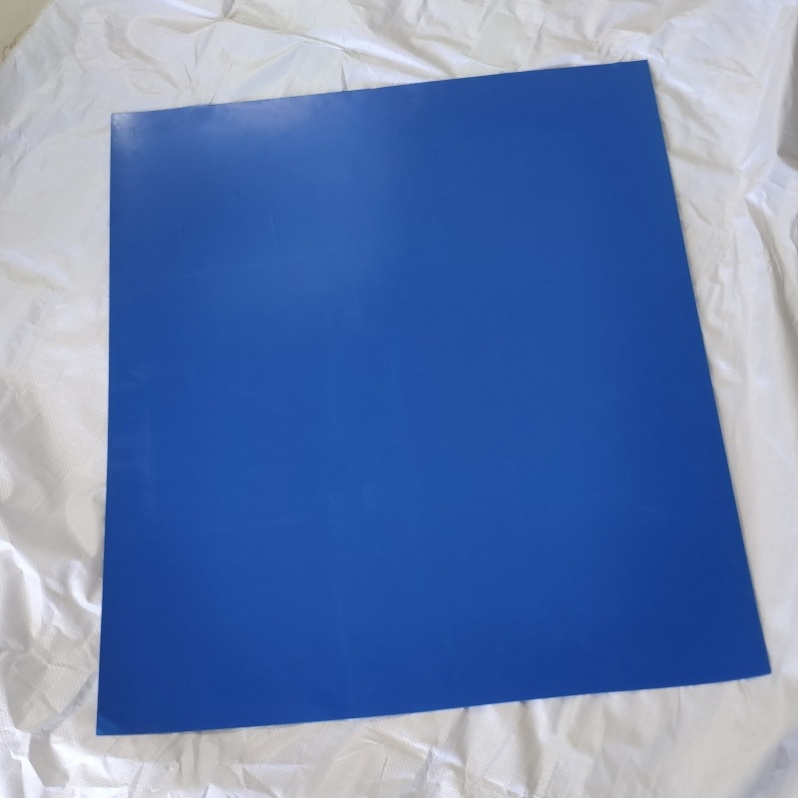

Uniform, opaque white finish: Provides excellent coverage (hides contents or substrate beneath) and a clean, professional look—ideal for branded packaging or components requiring a bright, consistent color.

Matte or glossy surface options:

Matte finish: Reduces glare and fingerprint marks, perfect for packaging where readability (e.g., printed logos, product info) is critical.

Glossy finish: Enhances visual appeal, adds a premium feel, and improves print adhesion for vibrant graphics.

Customizable thickness & size:

Thickness range: 0.2mm - 3.0mm (tailored to application needs—thin sheets for lightweight packaging, thicker sheets for rigid components).

Standard sizes: 1220mm x 2440mm (4ft x 8ft) or custom-cut dimensions to minimize material waste and fit your production line.

Available in food-contact-approved grades: Meets global food safety standards, including FDA 21 CFR Part 177.1640 (U.S.), EU Regulation (EC) No. 10/2011, and China GB 4806.6—safe for direct contact with dry, aqueous, and fatty foods.

Non-toxic, odorless, and tasteless: Ensures no migration of harmful substances into food, preserving the original flavor and quality of packaged products (e.g., snacks, baked goods, deli items).

High impact resistance (even at low temperatures): Withstands handling, stacking, and transportation without shattering or deforming—suitable for both disposable and reusable applications.

Lightweight construction: Reduces material usage, shipping costs, and end-product weight compared to alternative plastics (e.g., PVC, PET) or rigid materials (e.g., metal, wood).

Good chemical resistance: Resists oils, fats, and common food acids (e.g., citrus, vinegar) for food packaging; also withstands mild cleaning agents for reusable components.