FLEXIBLE pvc The Versatile World of Transparent PVC Flexible Film: Properties and Applications

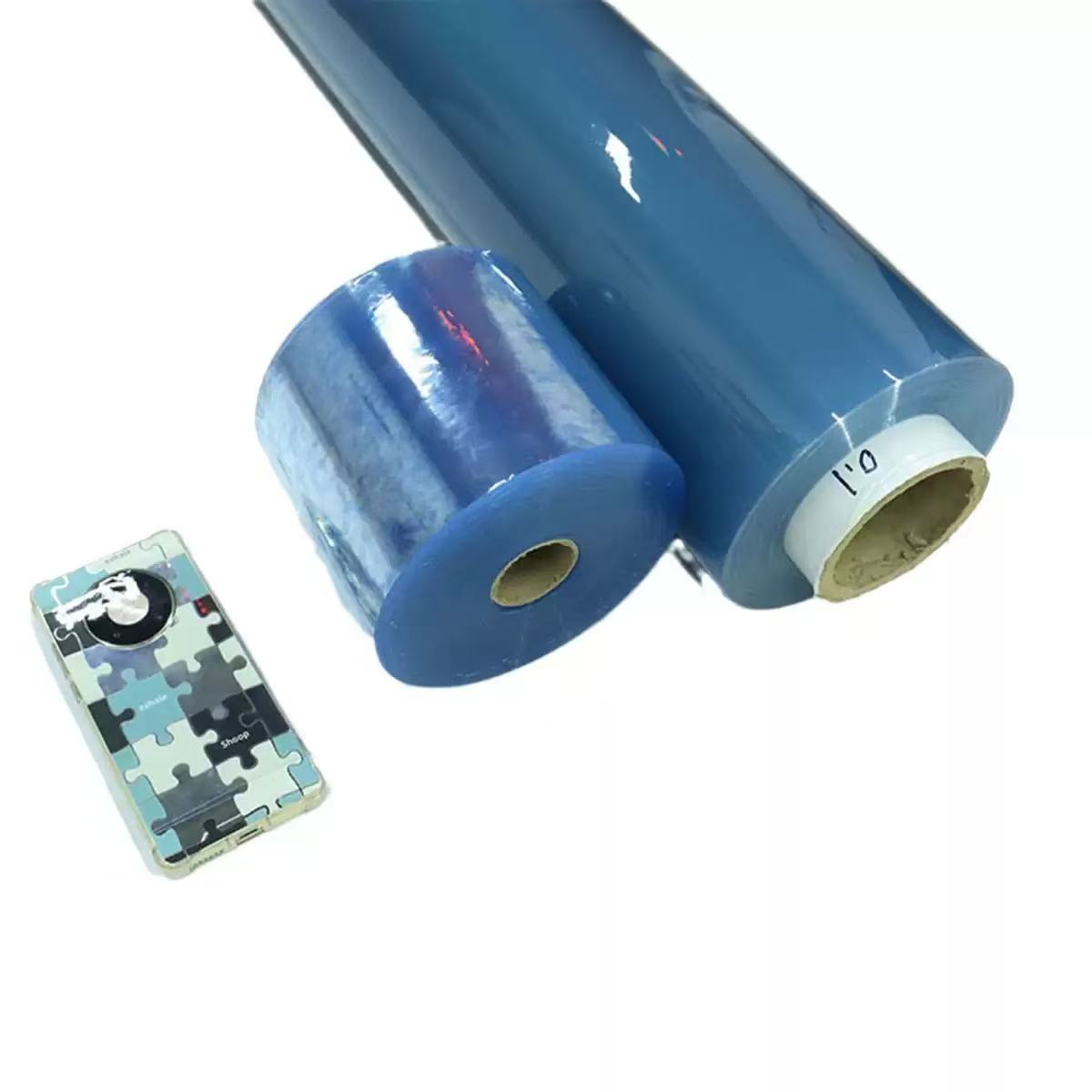

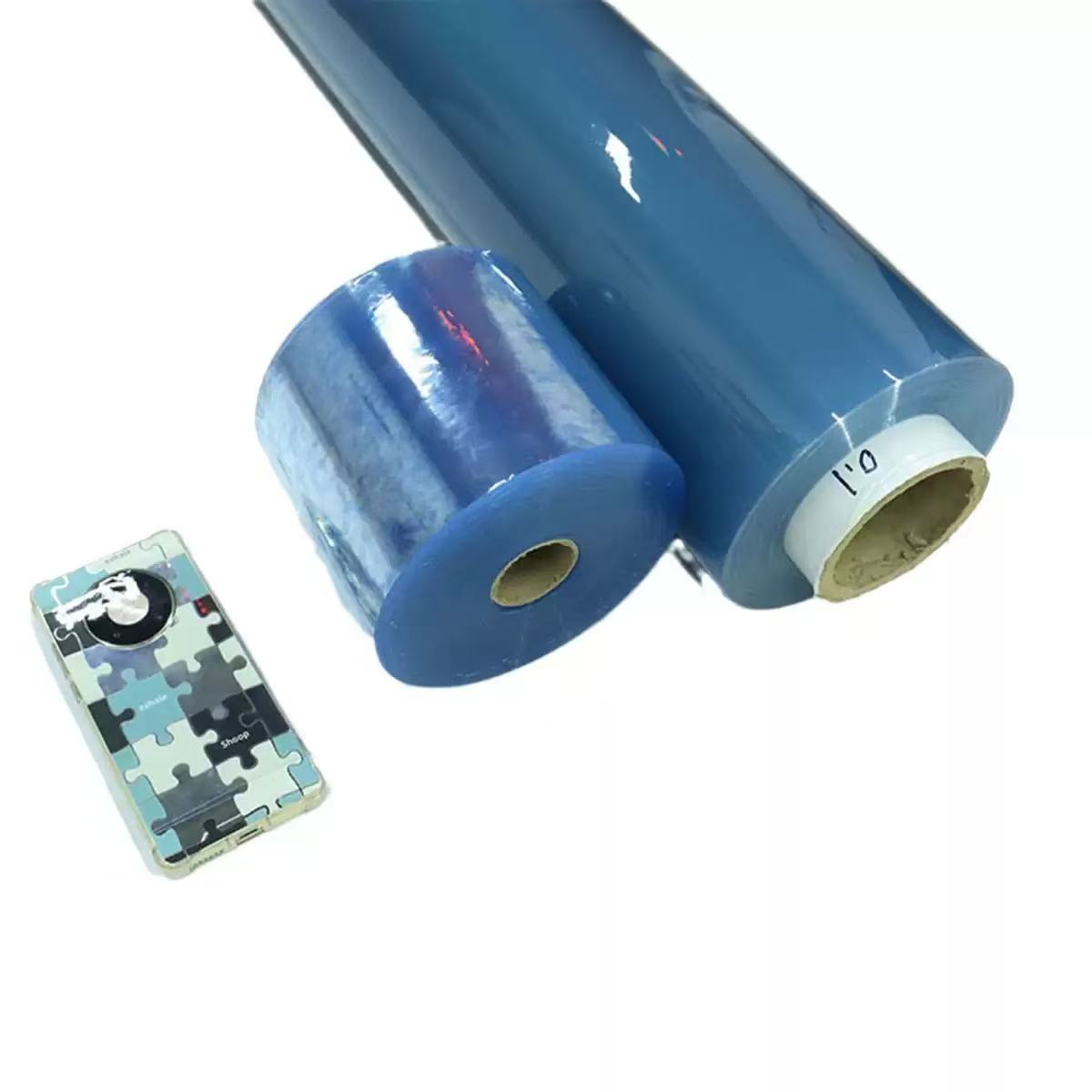

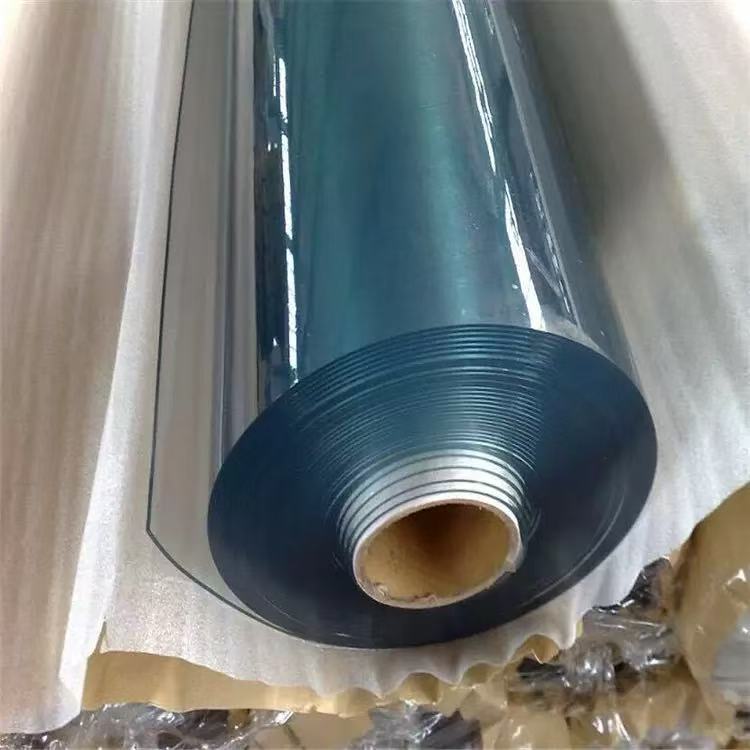

2025-11-20 14:29 Clear, Tough, and Everywhere: Why Transparent PVC Flexible Film Dominates Modern Industries  Transparent PVC flexible film, often called clear PVC film, soft PVC sheet, or vinyl film, is one of the most widely used plastic materials in the world. Thanks to its unique combination of optical clarity, mechanical toughness, chemical resistance, and cost-effectiveness, it appears in everything from everyday packaging to high-tech medical devices and heavy-duty industrial curtains. This colorless, flexible thermoplastic sheet has revolutionized numerous industries since its commercial breakthrough in the 1940s and continues to evolve with modern phthalate-free and eco-friendly formulations.1. Core Physical and Chemical Properties1.1 Exceptional Optical Clarity

Transparent PVC flexible film, often called clear PVC film, soft PVC sheet, or vinyl film, is one of the most widely used plastic materials in the world. Thanks to its unique combination of optical clarity, mechanical toughness, chemical resistance, and cost-effectiveness, it appears in everything from everyday packaging to high-tech medical devices and heavy-duty industrial curtains. This colorless, flexible thermoplastic sheet has revolutionized numerous industries since its commercial breakthrough in the 1940s and continues to evolve with modern phthalate-free and eco-friendly formulations.1. Core Physical and Chemical Properties1.1 Exceptional Optical Clarity

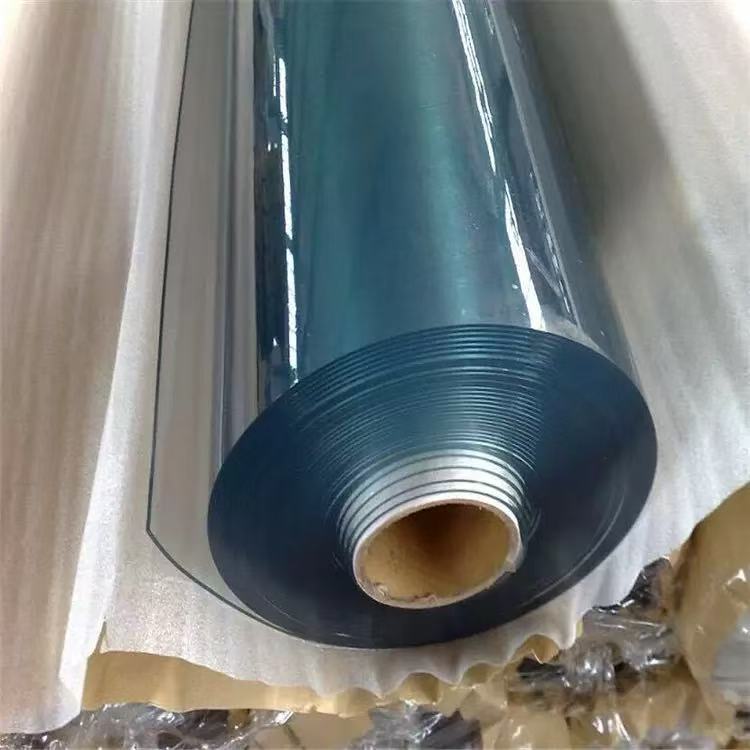

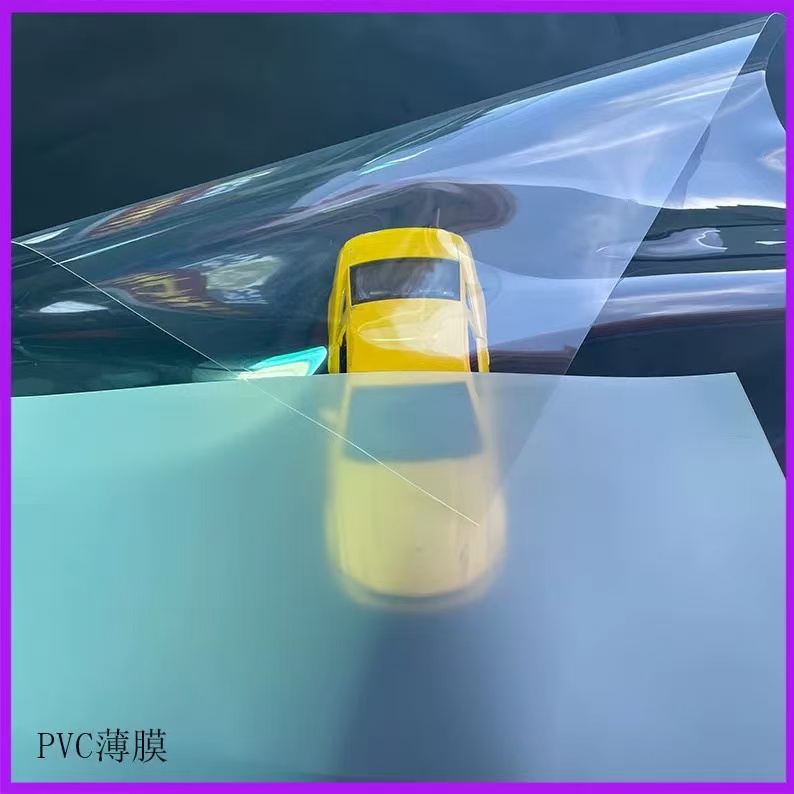

High-quality transparent PVC flexible film can achieve light transmission rates of 85–92%, rivaling glass in many applications while weighing only half as much. Advanced calendering and extrusion techniques, combined with low-haze plasticizers (DEHP replacements such as DOTP, DINCH, or bio-based plasticizers), ensure crystal-clear appearance even at thicknesses of 0.08 mm to 2 mm.1.2 Flexibility and Elasticity

Unlike rigid PVC, flexible PVC contains 25–50% plasticizer by weight, giving it rubber-like elasticity. It can be repeatedly bent, folded, and stretched without cracking. Typical elongation at break ranges from 200% to 450%, and it retains flexibility from –30 °C up to +70 °C (special grades reach –50 °C or +100 °C).1.3 Outstanding Durability and Tear Resistance

Transparent PVC flexible film exhibits excellent puncture and tear resistance. Elmendorf tear strength often exceeds 400 N/mm for 0.25 mm film. It resists abrasion, impact, and repeated flexing, making it ideal for environments where mechanical stress is constant. 1.4 Weather and UV Resistance

1.4 Weather and UV Resistance

Outdoor-grade transparent PVC films are formulated with UV stabilizers (HALS and benzotriazoles) and can withstand 3–7 years of direct sunlight in temperate climates without significant yellowing or brittleness. QUV accelerated weathering tests show that premium films retain >85% of initial clarity after 3000 hours of exposure.1.5 Chemical and Moisture Barrier

The material resists dilute acids, alkalis, alcohols, oils, and most household chemicals. Water vapor transmission rate (WVTR) is extremely low (~5–15 g/m²·24h at 0.1 mm thickness), providing an effective moisture barrier comparable to LDPE but with far superior clarity.1.6 Flame Retardancy and Electrical Properties

Many transparent PVC flexible films meet UL 94 V-0 or DIN 4102-B1 standards when formulated with phosphate or antimony-based flame retardants. Its volume resistivity (>10¹⁵ Ω·cm) and dielectric strength (~20–40 kV/mm) make it an excellent electrical insulator.1.7 Cold-Crack and Heat-Sealability

Super-clear PVC film can be RF (radio-frequency), ultrasonic, or hot-air welded, enabling fast production of inflatable structures, bags, and pouches. It also cold-cracks at temperatures well below most competing materials.2. Major Application Fields2.1 Packaging Industry

Transparent PVC flexible film dominates blister packaging, clamshell inserts, and shrink sleeves. Its sparkling clarity showcases products while providing tamper-evidence and moderate oxygen barrier. In food-contact applications, phthalate-free and FDA/EU 10/2011 compliant grades are standard. High-clarity twist-wrap film (20–40 µm) is still the material of choice for premium confectionery.2.2 Stationery and Office Products

The iconic “crystal clear” book covers, ring-binder pockets, ID card sleeves, and transparent folders are almost exclusively made from 80–250 µm super-clear PVC film. Anti-static and anti-scratch coatings are commonly added.2.3 Graphic Arts and Advertising

Large-format digital printing on transparent PVC film produces stunning backlit displays, window graphics, and exhibition banners. Cast PVC films with polymeric plasticizers accept UV-curable, solvent, eco-solvent, and latex inks with perfect adhesion and no edge curling.2.4 Inflatable Structures and Toys

Beach balls, swimming pool toys, advertising balloons, and emergency medical splints all rely on 0.18–0.50 mm transparent PVC film. RF-weldable grades allow high-speed production of perfectly airtight seams.2.5 Industrial Curtains and Strip Doors

In warehouses, cold storage facilities, and welding bays, 2–7 mm thick transparent PVC strip curtains provide visibility, thermal insulation (ΔT up to 30 °C), dust containment, and noise reduction while allowing forklift traffic. Anti-insect amber and welding green tints are available alongside crystal-clear versions. 2.6 Medical and Pharmaceutical Uses

2.6 Medical and Pharmaceutical Uses

Blood bags, IV bags, ostomy pouches, and flexible endoscope sheaths are manufactured from ultra-clean, gamma-sterilizable, phthalate-free transparent PVC film. Modern DINCH-plasticized medical grades exhibit virtually no plasticizer migration and meet USP Class VI and ISO 10993 biocompatibility standards.2.7 Automotive and Transportation

Instrument panel covers, convertible rear windows, and marine windshield replacements often use 0.5–1.0 mm high-clarity, UV-stabilized PVC film. Specialized “press-polished” grades achieve glass-like surface smoothness and distortion-free optics.2.8 Architecture and Interior Design

Transparent PVC flexible film appears as tensioned membranes in temporary structures, noise-barrier walls along highways, and flexible “glass” in greenhouses. Laminated safety versions with interlayer adhesion rival laminated glass at a fraction of the weight.2.9 Protective Covers and Tarpaulins

Boat covers, machinery dust shields, and outdoor furniture protection use reinforced transparent PVC film laminated to polyester scrim. These composites combine tear strength of over 500 N/5 cm with complete visibility of covered objects.3. Environmental and Regulatory EvolutionTraditional PVC flexible film relied heavily on DEHP (bis(2-ethylhexyl) phthalate), which triggered regulatory restrictions (REACH Annex XIV, California Prop 65, etc.). Since 2015, the industry has shifted dramatically toward phthalate-free alternatives: 5. Future Trends

5. Future Trends ConclusionFew materials can match the unique combination of glass-like clarity, rubber-like flexibility, durability, and affordability that transparent PVC flexible film delivers. From the moment you open a blister pack of medicine to the warehouse strip curtain that keeps cold air inside while letting workers see through, this remarkable material quietly enables modern life. With phthalate-free formulations now mainstream and recycling rates climbing, transparent PVC flexible film is not only here to stay, but it is becoming cleaner, safer, and more sustainable than ever before.

ConclusionFew materials can match the unique combination of glass-like clarity, rubber-like flexibility, durability, and affordability that transparent PVC flexible film delivers. From the moment you open a blister pack of medicine to the warehouse strip curtain that keeps cold air inside while letting workers see through, this remarkable material quietly enables modern life. With phthalate-free formulations now mainstream and recycling rates climbing, transparent PVC flexible film is not only here to stay, but it is becoming cleaner, safer, and more sustainable than ever before.

Transparent PVC flexible film, often called clear PVC film, soft PVC sheet, or vinyl film, is one of the most widely used plastic materials in the world. Thanks to its unique combination of optical clarity, mechanical toughness, chemical resistance, and cost-effectiveness, it appears in everything from everyday packaging to high-tech medical devices and heavy-duty industrial curtains. This colorless, flexible thermoplastic sheet has revolutionized numerous industries since its commercial breakthrough in the 1940s and continues to evolve with modern phthalate-free and eco-friendly formulations.1. Core Physical and Chemical Properties1.1 Exceptional Optical Clarity

Transparent PVC flexible film, often called clear PVC film, soft PVC sheet, or vinyl film, is one of the most widely used plastic materials in the world. Thanks to its unique combination of optical clarity, mechanical toughness, chemical resistance, and cost-effectiveness, it appears in everything from everyday packaging to high-tech medical devices and heavy-duty industrial curtains. This colorless, flexible thermoplastic sheet has revolutionized numerous industries since its commercial breakthrough in the 1940s and continues to evolve with modern phthalate-free and eco-friendly formulations.1. Core Physical and Chemical Properties1.1 Exceptional Optical ClarityHigh-quality transparent PVC flexible film can achieve light transmission rates of 85–92%, rivaling glass in many applications while weighing only half as much. Advanced calendering and extrusion techniques, combined with low-haze plasticizers (DEHP replacements such as DOTP, DINCH, or bio-based plasticizers), ensure crystal-clear appearance even at thicknesses of 0.08 mm to 2 mm.1.2 Flexibility and Elasticity

Unlike rigid PVC, flexible PVC contains 25–50% plasticizer by weight, giving it rubber-like elasticity. It can be repeatedly bent, folded, and stretched without cracking. Typical elongation at break ranges from 200% to 450%, and it retains flexibility from –30 °C up to +70 °C (special grades reach –50 °C or +100 °C).1.3 Outstanding Durability and Tear Resistance

Transparent PVC flexible film exhibits excellent puncture and tear resistance. Elmendorf tear strength often exceeds 400 N/mm for 0.25 mm film. It resists abrasion, impact, and repeated flexing, making it ideal for environments where mechanical stress is constant.

1.4 Weather and UV Resistance

1.4 Weather and UV ResistanceOutdoor-grade transparent PVC films are formulated with UV stabilizers (HALS and benzotriazoles) and can withstand 3–7 years of direct sunlight in temperate climates without significant yellowing or brittleness. QUV accelerated weathering tests show that premium films retain >85% of initial clarity after 3000 hours of exposure.1.5 Chemical and Moisture Barrier

The material resists dilute acids, alkalis, alcohols, oils, and most household chemicals. Water vapor transmission rate (WVTR) is extremely low (~5–15 g/m²·24h at 0.1 mm thickness), providing an effective moisture barrier comparable to LDPE but with far superior clarity.1.6 Flame Retardancy and Electrical Properties

Many transparent PVC flexible films meet UL 94 V-0 or DIN 4102-B1 standards when formulated with phosphate or antimony-based flame retardants. Its volume resistivity (>10¹⁵ Ω·cm) and dielectric strength (~20–40 kV/mm) make it an excellent electrical insulator.1.7 Cold-Crack and Heat-Sealability

Super-clear PVC film can be RF (radio-frequency), ultrasonic, or hot-air welded, enabling fast production of inflatable structures, bags, and pouches. It also cold-cracks at temperatures well below most competing materials.2. Major Application Fields2.1 Packaging Industry

Transparent PVC flexible film dominates blister packaging, clamshell inserts, and shrink sleeves. Its sparkling clarity showcases products while providing tamper-evidence and moderate oxygen barrier. In food-contact applications, phthalate-free and FDA/EU 10/2011 compliant grades are standard. High-clarity twist-wrap film (20–40 µm) is still the material of choice for premium confectionery.2.2 Stationery and Office Products

The iconic “crystal clear” book covers, ring-binder pockets, ID card sleeves, and transparent folders are almost exclusively made from 80–250 µm super-clear PVC film. Anti-static and anti-scratch coatings are commonly added.2.3 Graphic Arts and Advertising

Large-format digital printing on transparent PVC film produces stunning backlit displays, window graphics, and exhibition banners. Cast PVC films with polymeric plasticizers accept UV-curable, solvent, eco-solvent, and latex inks with perfect adhesion and no edge curling.2.4 Inflatable Structures and Toys

Beach balls, swimming pool toys, advertising balloons, and emergency medical splints all rely on 0.18–0.50 mm transparent PVC film. RF-weldable grades allow high-speed production of perfectly airtight seams.2.5 Industrial Curtains and Strip Doors

In warehouses, cold storage facilities, and welding bays, 2–7 mm thick transparent PVC strip curtains provide visibility, thermal insulation (ΔT up to 30 °C), dust containment, and noise reduction while allowing forklift traffic. Anti-insect amber and welding green tints are available alongside crystal-clear versions.

2.6 Medical and Pharmaceutical Uses

2.6 Medical and Pharmaceutical UsesBlood bags, IV bags, ostomy pouches, and flexible endoscope sheaths are manufactured from ultra-clean, gamma-sterilizable, phthalate-free transparent PVC film. Modern DINCH-plasticized medical grades exhibit virtually no plasticizer migration and meet USP Class VI and ISO 10993 biocompatibility standards.2.7 Automotive and Transportation

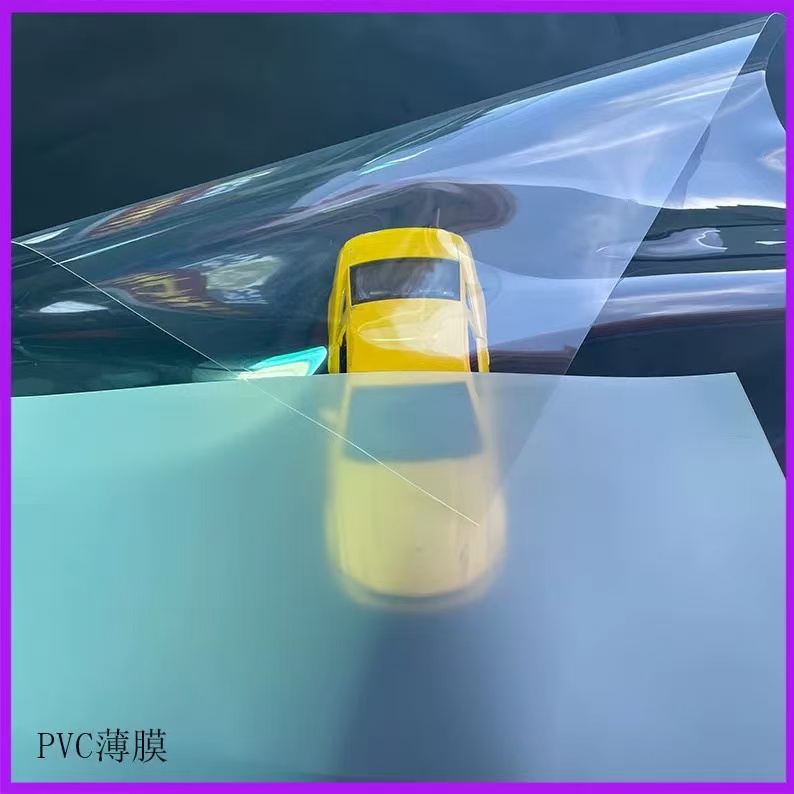

Instrument panel covers, convertible rear windows, and marine windshield replacements often use 0.5–1.0 mm high-clarity, UV-stabilized PVC film. Specialized “press-polished” grades achieve glass-like surface smoothness and distortion-free optics.2.8 Architecture and Interior Design

Transparent PVC flexible film appears as tensioned membranes in temporary structures, noise-barrier walls along highways, and flexible “glass” in greenhouses. Laminated safety versions with interlayer adhesion rival laminated glass at a fraction of the weight.2.9 Protective Covers and Tarpaulins

Boat covers, machinery dust shields, and outdoor furniture protection use reinforced transparent PVC film laminated to polyester scrim. These composites combine tear strength of over 500 N/5 cm with complete visibility of covered objects.3. Environmental and Regulatory EvolutionTraditional PVC flexible film relied heavily on DEHP (bis(2-ethylhexyl) phthalate), which triggered regulatory restrictions (REACH Annex XIV, California Prop 65, etc.). Since 2015, the industry has shifted dramatically toward phthalate-free alternatives:

DOTP (dioctyl terephthalate)

DINCH (1,2-cyclohexane dicarboxylic acid diisononyl ester)

ESO (epoxidized soybean oil) + polymeric plasticizers

Bio-based plasticizers derived from citric, adipic, or sebacic acid

5. Future Trends

5. Future TrendsBio-attributed and mass-balance PVC using renewable ethylene from sugarcane

Fully bio-based flexible films (PVC-free) that match current clarity and welding performance

Nano-composite clear PVC films with self-healing or anti-fog permanent coatings

Integration of phase-change materials inside multilayer transparent PVC laminates for temperature-regulating greenhouses

ConclusionFew materials can match the unique combination of glass-like clarity, rubber-like flexibility, durability, and affordability that transparent PVC flexible film delivers. From the moment you open a blister pack of medicine to the warehouse strip curtain that keeps cold air inside while letting workers see through, this remarkable material quietly enables modern life. With phthalate-free formulations now mainstream and recycling rates climbing, transparent PVC flexible film is not only here to stay, but it is becoming cleaner, safer, and more sustainable than ever before.

ConclusionFew materials can match the unique combination of glass-like clarity, rubber-like flexibility, durability, and affordability that transparent PVC flexible film delivers. From the moment you open a blister pack of medicine to the warehouse strip curtain that keeps cold air inside while letting workers see through, this remarkable material quietly enables modern life. With phthalate-free formulations now mainstream and recycling rates climbing, transparent PVC flexible film is not only here to stay, but it is becoming cleaner, safer, and more sustainable than ever before.

Get the latest price? We'll respond as soon as possible(within 12 hours)