- Home

- >

News

Tableware, whether it's delicate porcelain, fine glassware, or sturdy cutlery, requires protection to maintain its pristine condition. Transparent PET film offers an excellent solution for safeguarding tableware during storage and transportation. The crystal-clear transparency of the film allows the beauty of the tableware to shine through while providing a protective barrier. It prevents scratches, dust, and moisture from damaging the tableware. When wrapped around tableware items, the film conforms to their shape, providing a snug fit and ensuring that they remain secure.

Transparent Pet film, with its unique properties and versatility, has found extensive applications in various industries. In this article, we will explore the uses of transparent Pet film in different fields at room temperature, including blister jewelry packaging, blister tool packaging, blister pharmaceutical packaging, and insulation boards. Through vivid descriptions and real-life examples, we will showcase the importance and advantages of this remarkable material.

Blister Pharmaceutical Packaging The pharmaceutical industry also relies heavily on transparent PET film for packaging. Similar to food packaging, the transparency of PET film allows for easy inspection of the contents, ensuring the integrity and quality of the medications. PET film provides a barrier against moisture, light, and oxygen, which can degrade the potency of drugs. This is especially important for sensitive medications such as tablets, capsules, and powders.

Antistatic and Thermoformable PET Film: Wonders of Versatility by In the bustling metropolis, one young, innovative entrepreneur named Lily Chang was going to change the world of materials. It was the year 2024, and Lily had just discovered the astonishing properties of antistatic and thermoformable PET film. Little did she know that this would be an exciting journey that would affect many industries and change lives. The finding of sustainable and practical solutions for day-to-day problems had always remained close to her heart. Progressing further in the world of materials, she found anti-static thermoformable PET film. Curious about its capabilities, she started to find ways where it can be used. It was on one such day while sitting in the small office and gazing out at the skyline of the city that she finally thought that with such film, she might print out A4 sheets that are singularly special. She was so thrilled by the very idea that soon she got down to work on it. Lily then called a local printing company and described her idea. To begin with, the printing company was somewhat skeptical, but once they had samples of the PET film, skepticism turned into interest. Together they began experimenting with different ways of printing the film and soon discovered that it could bear excellent bright prints. The news began to circulate about Lily's printable A4 PET film sheets. Their unique features increased the attraction of students and professionals alike towards these sheets. Because of the antistatic property, prints do not possess static electricity and hence are easily handleable and storable. The thermoformable nature of the film opens more ways of creative usage, such as making note cards or bookmarks in an arbitrary form. As the news spread, Lily was invited to present the product at a local trade show. She was happy to expose her innovation to more people, so she accepted the invitation. The booth was flooded with visitors during the trade show. Still, people were further surprised to see the versatility of PET film. One of them was Alex, a graphic designer who was pretty impressed and visualized using these sheets for his design projects. Alex walked up to Lily and started a conversation with her. Soon, both found that they shared an interest in innovation and design. Alex also mentioned to her about the PET film for customized packaging and how she could join on a project to work with it. The idea thrilled Lily, and they did not delay in starting their work. They started researching all types of packaging needs and came up with a few ideas. One of the ideas was to do some innovative packaging for a local cosmetics brand. The cosmetic company was looking for varnish and striking green packaging solutions. Lily and Alex presented their idea of using antistatic and thermoformable PET film. Interested, the company decided to give it a try. Thus, Lily and Alex were putting great effort into designing packaging and then actually making it. They used the thermoformable property of the film to create custom shapes that would fit the cosmetics products perfectly. The antistatic feature would protect them against electrostatic discharges during transport and storage. The result was amazing. The packaging was beautiful, but not only that-it was functional. It called the attention of the consumers and soon became a hit. The cosmetics company loved the result and ordered more of such packaging. Buoyed by the success, Lily and Alex continued to explore other applications of the PET film. They soon turned their attention to food and pharmaceutical industries. Safety and freshness are key factors in the food industry. Lily and Alex realized that the antistatic and thermoformable PET film would assist in maintaining the freshness of the food and containing no contaminants. They had a package designed with the local food manufacturer for his products. This proved ideal for properties such as packaging of food. Antistatic dispensers prohibited the adherence of dust and other particles onto the packagings, while the thermoformable property allowed customized shapes, which fit different food items. In this case, this turned out to be effective yet attractive packaging. The pharmaceutical industry demands sterile and safe packaging. Lily and Alex worked with a pharmaceutical company to develop packaging that would meet these demands. The PET film instantiated an antistatic property of the film which prevented the build-up of the charges capable of damaging some sensitive medications. The thermoformability was adjustable for those custom-designed packaging meant to secure the drugs during transportation and storage. Here, both Lily and Alex had a reason to look forward to further opportunities once their projects were successful in food and pharmaceuticals producing industries. As a matter of fact, they were invited as guest speakers in industry conferences where they shared their experiences with others. As they got more and more popular, one day, Lily and Alex were approached by a local interior designer. The interior designer wanted something very special for his next big decoration project. Lily and Alex recommended the PET film. They worked with designers for the creation of custom walls and decorative panels. The thermoformability of the film allowed for creative designs and figures, along with an antistatic feature of the decorations, which made them without static electric properties, thus giving an amazing look of space. In the field of glass decoration, Lily and Alex also carved their niche. They also developed a method of applying the PET film to glass surfaces to make privacy screens, decorative windows, and other unique glass features. Because of the properties of this film, installation and removal were pretty easy; thus, it found its place in residential and commercial usages. As the year drew to a close, Lily and Alex looked back with pride to see how it had been. They had taken an easily available material and molded it into a multiutility solution making a difference in various industries. From printable A4 sheets to creative packaging, decoration items, up to glass enhancement, the list of applications for thermoformable PET film is endless. Their story of Lily and Alex had emphasized the force of innovation and teamwork. They had proved that with just a little creativity and determination, even one simple material could go a long way into changing the world. They knew that their journey of thermoformable and antistatic PET film was far from over as they looked to the future. Actually, they were pretty excited about the new applications of the material and the new opportunities. Conclusion: This is quite a remarkable story involving discovery and use of antistatic and thermoformable PET film by Lily Chang and Alex. It's reached into printing and packaging, food, pharmaceuticals, decoration, and the decoration of glass. Their traits have proven-you just need to think differently, and you will definitely find something which is suitable and applicable in everyday industrial problems. With ever-growing sustainability concerns and the need for versatile materials, antistatic, and thermoformable PET film possibly holds a bright future for any who would dare to work and venture into it.

《The Versatile Red PET Film: Transforming Industries》 Date: August 28, 2023 Location: Across the Globe Characters: Manufacturers, Designers, Consumers In the ever-evolving landscape of materials and packaging, red PET film has emerged as a star player, making its mark in various industries and transforming the way products are presented and protected. The story begins with the growing demand for unique and eye-catching packaging solutions. Manufacturers, constantly on the lookout for materials that can set their products apart on crowded store shelves, discovered the potential of red PET film. This vibrant and durable material offered a combination of aesthetic appeal and functionality that was hard to resist. In the packaging industry, red PET film quickly became a favorite. Its vivid color and glossy finish added a touch of elegance and sophistication to a wide range of products. From cosmetics to electronics, the film's ability to enhance the visual appeal of packaging was undeniable. Designers were inspired by its versatility, creating innovative packaging designs that caught the attention of consumers. One of the significant applications of red PET film was in food packaging. With its excellent barrier properties, it helped keep food fresh and protected from external elements. The bright red color also made food packages stand out, attracting customers in supermarkets and grocery stores. Food manufacturers soon realized the benefits of using red PET film not only for its aesthetic value but also for its practicality. In the realm of药品包装 (pharmaceutical packaging), red PET film played a crucial role as well. It provided a secure and tamper-evident packaging solution for medications. The color red often symbolizes urgency and importance, which was fitting for pharmaceutical products. The film's durability ensured that medications remained intact and safe during transportation and storage. Flower packaging was another area where red PET film made a significant impact. Florists around the world began using the film to wrap bouquets, adding a pop of color and elegance. The film not only protected the flowers but also enhanced their beauty, making them more appealing to customers. Whether it was a simple bouquet for a loved one or an elaborate floral arrangement for a special occasion, red PET film added that extra touch of charm. The decoration industry also embraced red PET film. Interior designers and decorators used it to create unique wall coverings, furniture accents, and decorative elements. The film's vivid color and reflective surface added a touch of glamour and modernity to any space. From trendy cafes to luxurious hotels, red PET film was used to create stunning interiors that left a lasting impression. Glass改色 (glass coloring) was yet another application of red PET film. Instead of traditional methods of coloring glass, which can be expensive and time-consuming, manufacturers and designers discovered that red PET film could be easily applied to glass surfaces to achieve a similar effect. This not only saved time and money but also offered a more flexible and customizable solution. As the use of red PET film spread across different industries, its effects became more and more apparent. Consumers were drawn to products packaged in red PET film, perceiving them as higher quality and more desirable. Manufacturers saw an increase in sales and brand recognition. The film's durability also led to reduced waste, as it could be recycled and reused. In conclusion, red PET film has truly revolutionized various industries with its versatility, aesthetic appeal, and functionality. From packaging to decoration and everything in between, this remarkable material has proven to be a game-changer. As we look to the future, it is likely that red PET film will continue to play an important role in shaping the way we package, present, and decorate products. Its vibrant color and durability will continue to inspire manufacturers and designers, while its practical benefits will satisfy the demands of consumers. The story of red PET film is one of innovation, transformation, and endless possibilities.

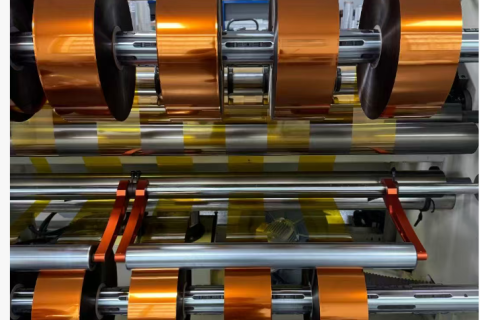

New APET Film Manufacturing Facility Opens in Dallas, Texas August 20, 2023 — Dallas, Texas The world of packaging witnessed a significant event today with the grand opening of a new production facility by EcoPack Industries, one of the top manufacturers of sustainable packaging materials in Dallas, Texas. In that respect, the facility also started producing APET film—a very famous material used in a myriad of different package applications. The presence of key house players in the industry, local government authorities, and company executives at the grand opening made this event very monumental to the company and the packaging industry at large. Key People Involved The event was led by EcoPack CEO Sarah Mitchell, who was flanked by Texas Governor Jake Martinez and Dallas Mayor Emily Harper. The representatives that showed up were from the food, pharmaceutical, and consumer goods industries, demonstrating just how broad the reach is that this new facility will have across multiple sectors. Causes Behind the Expansion The investment in this new facility responded to an increasing demand for high-performance, sustainable packaging solutions. APET film is known for its clarity, strength, and recyclability; it has been dominant in popularity as companies are shifting to more environmentally-friendly packaging materials. "The demand for APET film will only accelerate as businesses reduce their impact on the environment while maintaining product quality and appeal," according to Sarah Mitchell, vice president of Product Development and Commercialization at Munn Packaging, who spoke at the event. The Manufacturing Process The Dallas facility is equipped with state-of-the-art technology in the manufacture of high-quality APET film. The manufacturing process initiates with the extrusion of PET pellets, further stretched to create thin and flexible sheets of APET film. Later, these sheets are cut and processed to specific thickness and size requirements, thereby maintaining dimensions needed for many different packaging applications. The facility will also be designed with sustainability in mind, as it will feature energy-efficient machinery and a closed-loop recycling system that reuses production waste. "We are committed to not only providing top-tier packaging materials but also doing so in a way that minimizes our impact on the environment," Mitchell emphasized. Results of the Expansion With the new facility, the production capacity of EcoPack is expected to go up several-fold, thus helping the company meet growing demand for APET film in North America. The facility will have a projected output of over 20,000 tons a year of APET film, meant for the food, pharmaceutical, and consumer goods industries. Not only has the facility increased production, but more than 300 new jobs have been created in the Dallas area, contributing to an economic boom locally. Customers will be able to see the first batch of APET film shipped out at the end of September 2024. Effects on the Industry This facility is going to make a real difference in the packaging industry. The standards in packaging materials will be increased with the increased supply of high-quality, sustainable APET film, thus helping EcoPack in enhancing new standards for the same. Probably, this will further drive innovation in packaging design, particularly in sectors where sustainability and product presentation are key concerns. This facility's foray into sustainable production practices will set examples and influence other manufacturers to follow suit in an eco-friendly mode. "This facility isn't about raising our output; it's about leading the industry," Mitchell said. Conclusion The opening of EcoPack's new APET film manufacturing facility in Dallas marked another major step forward in the progress of the packaging industry. With increased capacity, green operations, and the creation of jobs, this facility is bound to meet the rising demand for quality and green packaging solutions. As the first products roll off in the coming weeks, the reverberations from this expansion will echo down the supply chain, cementing EcoPack's lead in the packaging industry.

An application of the BPET conductive material boosts the electronics industry. August 2024, Shanghai, Global Electronics Manufacturing Exhibition; Zhang Qiang: technical director of a leading electronics materials R&D company. In August 2024, at the Global Electronics Manufacturing Exhibition held in Shanghai, a new type of conductive material took center stage. The Technical Director, Zhang Qiang, of one of the key Electronics Materials R&D enterprises, has brought along with him a team to introduce very latest BPET (Biaxially Oriented Polyethylene Terephthalate) conductive material. This launch marks the large step forward applying static protection and conductive materials within the electronics industry. Background: Help Needed to Meet Increased Demand for Static Protection With their ever-growing sophistication and complication, electronic products are also requiring more dependable static protection and conductive materials. Having noticed this emerging market demand, Zhang Qiang and his group embarked on a multi-year development program in search of creating a high-performance material to satisfy the demand. "We all noticed that all kinds of conductive materials available in the market had a number of problems, such as low transparency and unstable conductivity, which limited their usage in high-end electronic devices," Zhang Qiang explained during the launch. "It is this that moved us to develop a material that links high transparency, brightness, and stable conductive performance to serve the industry much better." Process: Overcoming Technical Challenges and Enhancing Performance The BPET material is produced with the help of imported production lines to ensure high transparency, brightness, and crystal-free surfaces with excellent flatness. Food grade slip agents were added by the team into the material to give it excellent surface smoothness, good processability, and well-preserved conductive properties. BPET sheets come in various specifications, thereby allowing for high production capacity at superior quality and cost-effectiveness. This is an environment-friendly and non-toxic material that meets QS food safety certification and passes the European Union's SGS environmental certification, hence suitable for industries with strict compliance criteria to safety and the environment. The following are several conductive grades for the materials: - Permanent Conductive Sheet: $10^10$ ohms - Permanent Antistatic Sheet: 10^10 ohms - Permanent Semi-Conductive Sheet: 10^6-10^9 ohms These variations show steady and smooth conductive performance, which ensures the stability and reliability of products for various applications. Besides, BPET can be processed into flat sheets, slit, and laminated; while PET-G and GAG grades are especially suitable for producing high-end electronic products. Result: Good Market Response and Wide Industrial Application In the exhibition, BPET conductive material was very fast.

The Rise of PET Sheets in Food Packaging and Labeling: A Sustainable Choice *Date: August 9, 2023 Location: Global Market Key Stakeholders: PET Manufacturers, Food Industry, Environmental Organizations* Introduction Polyethylene Terephthalate (PET) sheets have rapidly gained traction in recent years as an innovative material in the packaging industry. Renowned for their excellent toughness, high strength, and superior transparency, PET sheets have become a favored choice for food packaging and labeling applications. The material’s ability to be printed on, recycled, and its environmentally friendly properties, particularly its non-toxic combustion process, have further solidified its position as a leading packaging solution. This article explores how PET sheets are transforming the food packaging and labeling landscape, highlighting key developments and their impact on the market. Background PET sheets were developed to address the growing demand for materials that not only provide strong protective packaging but also align with global environmental sustainability goals. With the increasing awareness and concern over environmental degradation, particularly from non-recyclable plastics, the food industry began searching for alternatives that could offer both functionality and eco-friendliness. PET sheets, with their remarkable features, emerged as an ideal solution, gradually gaining popularity among consumers, producers, and environmental advocates alike. Features and Advantages 1. Transparency and Gloss: PET sheets offer exceptional transparency and surface gloss, making them highly effective in showcasing food products. This feature is especially valuable in retail environments, where product visibility is a critical factor in consumer decision-making. 2. Surface Decoration: The surface of PET sheets is highly receptive to decoration without the need for additional surface treatments. They are easy to print on, emboss, and even metalize using vacuum metal coating, making them ideal for creating attractive and informative labels. 3. Mechanical Strength: The robust mechanical strength of PET sheets ensures that food products are well-protected during transportation and handling, reducing the risk of damage and spoilage. 4. Barrier Properties: PET’s excellent barrier properties against oxygen and water vapor help preserve the freshness and quality of food products, extending their shelf life. 5. Chemical Resistance: PET sheets are resistant to various chemicals, which is crucial for packaging foods that may come into contact with reactive substances. 6. Safety and Hygiene: Non-toxic and compliant with stringent hygiene standards (such as GB13113-91), PET sheets are suitable for packaging food, pharmaceuticals, and medical devices. They can also be sterilized using radiation, ensuring the safety and integrity of the packaged goods. 7. Environmental Compatibility: PET is not only recyclable but also burns without releasing harmful substances, making it a key material in the global push for sustainable packaging solutions. Its excellent thermoforming capabilities allow it to be easily molded into various shapes, further enhancing its versatility in packaging applications. Event and Impact In recent years, several leading food manufacturers have transitioned to using PET sheets for their packaging and labeling needs. This shift was primarily driven by the material’s superior performance and environmental benefits. For instance, in a significant move in 2023, a global food giant replaced its traditional PVC packaging with PET for its entire line of snack products. This decision was lauded by environmental groups and resulted in a notable increase in sales, as consumers responded positively to the company’s commitment to sustainability. Moreover, the adoption of PET sheets in labeling has revolutionized the way food products are presented and marketed. The ability to easily print high-quality graphics and text directly onto the packaging has enabled brands to create more engaging and informative labels, enhancing their appeal on store shelves. Outcome and Future Prospects The widespread adoption of PET sheets in food packaging and labeling has led to a significant reduction in the environmental footprint of the packaging industry. The material’s recyclability and safe combustion have addressed many of the environmental concerns associated with traditional packaging materials. As a result, PET sheets have not only met the immediate needs of the food industry but also contributed to the long-term goal of reducing plastic waste and promoting sustainability. Looking ahead, the market for PET sheets is expected to continue growing, with more industries recognizing their value. Ongoing advancements in PET technology, such as improved barrier properties and enhanced printability, will likely further solidify PET’s position as the material of choice for food packaging and labeling. In an era where environmental sustainability is no longer an option but a necessity, PET sheets are set to play a pivotal role in shaping the future of packaging.

Anti-Static Protection Static electricity can cause damage to electronic components and interfere with the functioning of sensitive equipment. Transparent PET rigid film with anti-static properties is designed to dissipate static charge and prevent electrostatic discharge.

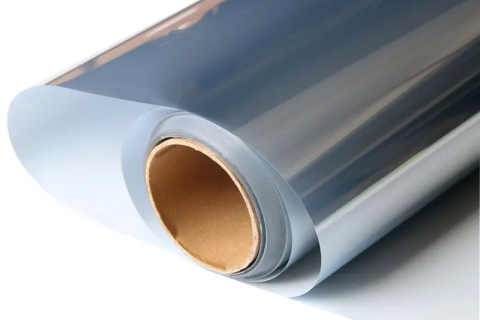

Name: PET Plastic film roll SizeTk:0.01-0.9mm, h100-1200mm MaterialPET/Customized Color/printingTransparent/customized PackagingCartons/customized OEM/ODMAccepeted MOQ1000KG UsagePHARMA,Vegetable/Fruit/Meat, biscuits FeatureHigh durability, eco-friendly, compression resistance AdvantageCompetitive price, consistent quality, 24 hours online service

PS in Food Thermoforming Packaging—Ease of Use Brought to the Fore in an Industry Conference Date: 28 July 2024 Location: Chicago, Illinois Event: International Food Packaging Expo The International Food Packaging Expo, held on July 28, 2024, in Chicago, Illinois, gathered a number of industry leaders and experts to present the current developments and trends on food packaging. Among the most exciting topics presented was the ease and benefits of using Polystyrene in food thermoforming packaging. Key Speakers: - Dr. Emily Carter, Professor of Material Science at MIT - John Stevens, CEO FreshPack Solutions Maria Gonzalez, Sustainability Director at EcoPack Inc. Session Overview: The session was opened with a thorough presentation by Dr. Emily Carter on the material properties of PS. She elaborated on how this versatile, flexible, very affordable material is perfect for all possible uses in the food packaging industry. According to Dr. Carter, PS is very easy to mold into different shapes and sizes; thus, it provides tailored solutions to meet all requirements for a particular product. This was followed by John Stevens, who shared his company's experience in using PS for its packaging needs. FreshPack Solutions is a leader in ready-to-eat meal packaging, where it has dealt extensively with PS because it is lightweight but strong at the same time. Stevens elaborated on how good insulation properties keep the temperature of food products intact—hot foods stay hot, cold foods stay cold through transportation and storage. This has greatly improved customer satisfaction while reducing food waste. Maria Gonzalez continued to address the environmental issues with PS. She acknowledged the difficulties but also put a positive spin on strides made in recycling technology. Gonzalez talked about how EcoPack Inc. has implemented effective recycling programs that turn used PS packaging into new products. She displayed a number of slides showing successful case studies where PS recycling had reduced the company's ecological footprint. Outcome: The session was concluded with an interactive panel discussion, involving questions and opinions from the audience. Many attendees gained a new appreciation for the role PS plays in food packaging, specifically the cost and efficiency of thermoforming. It really brought home the continued efforts in place to make PS more recyclable by being focused on sustainability and minimizing environmental impacts. The conference not only reaffirmed the value of PS in food thermoforming packaging but also created immense collaboration among all players to move toward progress in sustainability. There was positive response from the participants, demonstrating the need for continuous innovation and adaptation in the food packaging sector. Conclusion: The International Food Packaging Expo presented an opportunity where several advantages of PS were demonstrated in food thermoforming packaging. According to the active and leading experts in the discussions and presentations, PS is outstanding with great convenience, affordability, and the potential for use in a sustainable manner. Going forward into the future, the association of enhanced recycling technologies with innovative packaging solutions will be important in ensuring that PS stays relevant and responsible for food packaging. For more information about the International Food Packaging Expo and additional events, visit www.foodpackagingexpo.com.

Name:PET Plastic film roll SizeTk:0.1-0.9mm, h100-1200mm MaterialPET/Customized Color/printingTransparent/customized PackagingCartons/customized OEM/ODMAccepeted MOQ1000KG UsagePHARMA,Vegetable/Fruit/Meat, biscuits FeatureHigh durability, eco-friendly, compression resistance AdvantageCompetitive price, consistent quality, 24 hours online service