- Home

- >

News

NamePET ICE CUPS Size9-60 OZ MaterialPET/PP/Customized Color/printingTransparent/customized PackagingCartons/customized OEM/ODMAccepeted MOQ1000KG UsageICE CUP/ Vegetable/Fruit/Meat FeatureHigh durability, eco-friendly, compression resistance AdvantageCompetitive price, consistent quality, 24 hours online service

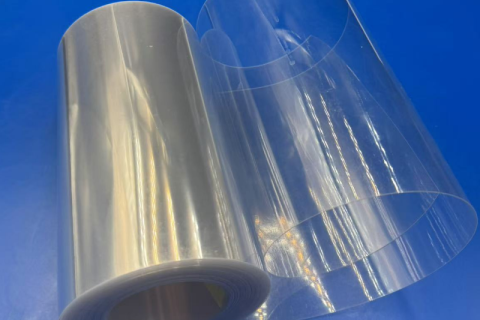

New Breakthrough in Transfer Printing: Innovative pET Films Unveiled *August 18, 2023, Shenzhen, China* — In a major development for the printing industry, Shenzhen GlobalTech Materials, a leading manufacturer of advanced materials, has unveiled its latest innovation in transfer printing: a new line of high-performance polyethylene terephthalate (pET) films. This breakthrough is set to revolutionize the industry by significantly enhancing the quality and durability of printed images on a wide range of surfaces. The Cause: Demand for Superior Printing Solutions The growing demand for high-quality, durable printing on textiles, industrial labels, and packaging has driven the need for advanced materials that can meet these challenges. Traditional materials often fall short in terms of thermal stability, chemical resistance, and optical clarity, leading to compromised print quality. Recognizing this gap, Shenzhen GlobalTech Materials embarked on a mission to develop a pET film that could address these limitations. The Process: A Collaborative Effort The development of the new pET film was a collaborative effort involving a team of material scientists, engineers, and industry experts. Over the past two years, the team has conducted extensive research and testing at GlobalTech’s state-of-the-art R&D facility in Shenzhen. The project was led by Dr. Li Wen, a renowned expert in polymer materials, who emphasized the importance of creating a film that could withstand the rigorous demands of modern transfer printing processes. "We wanted to create a pET film that not only meets the current needs of the industry but also anticipates future demands," said Dr. Li during the product launch event. "Our goal was to enhance every aspect of the film's performance, from thermal stability to tensile strength, to ensure that our customers can achieve the highest quality prints." The Product: New pET Films The newly introduced pET films boast several innovative features that set them apart from existing products. These include: - Enhanced Thermal Stability: The films can withstand higher temperatures without deforming, ensuring that printed images remain sharp and undistorted. - Superior Chemical Resistance: The films offer improved resistance to a wide range of chemicals, extending the lifespan of printed materials even in harsh environments. - Increased Optical Clarity: The new pET films provide better light transmission and color accuracy, resulting in more vibrant and precise prints. - Eco-Friendly Composition: In line with GlobalTech’s commitment to sustainability, the films are fully recyclable, contributing to reduced environmental impact. The Result: Industry-Wide Impact The introduction of these advanced pET films is expected to have a significant impact on the transfer printing industry. Initial tests by GlobalTech's key clients have shown remarkable improvements in print quality and durability across various applications, from textile printing to industrial labeling. Jiang Wei, CEO of Shenzhen GlobalTech Materials, expressed confidence that this new product line would set a new industry standard. "This is a game-changer for the transfer printing industry. Our clients have been asking for a solution that delivers both quality and longevity, and we believe these new pET films deliver on both fronts." The Effect: Anticipated Market Growth With the launch of these advanced pET films, Shenzhen GlobalTech Materials is poised to capture a significant share of the global transfer printing market. The company has already secured orders from major manufacturers in Europe and North America, signaling strong demand for the new product. Industry analysts predict that this innovation will lead to widespread adoption of pET films in sectors that rely on high-quality transfer printing, such as fashion, electronics, and automotive industries. The environmental benefits of the recyclable pET films also align with the increasing global emphasis on sustainable manufacturing practices, further boosting their appeal. Conclusion The launch of Shenzhen GlobalTech Materials’ new pET films marks a significant milestone in the transfer printing industry. As the demand for superior, durable, and sustainable printing solutions continues to rise, these innovative films are expected to play a pivotal role in shaping the future of the industry, setting new benchmarks for quality and performance.

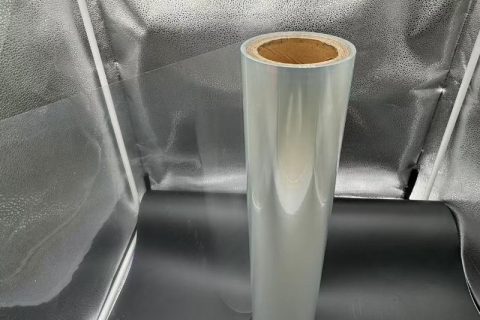

Material: petg shrink FILM ROLL Thickness 0.012mm/customization Size: 100mm/Customization GRADE: Food grade film color: transparent/white/ customization location: china usage :for food ,electronic ,fruit packing

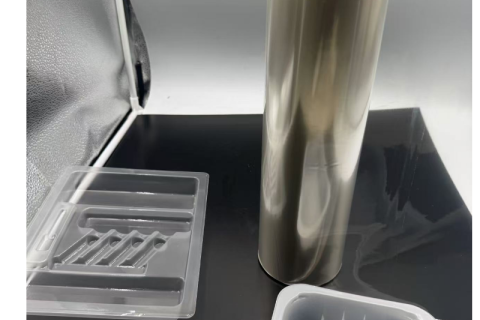

In the world of packaging, innovation is constantly driving the industry forward. One such innovation that has gained significant prominence in recent years is the use of multi-Pet films in blister packaging.

NamePET-DTF film roll SizeTk:0.012-0.023mm, h100-1200mm MaterialPETG/Customized Color/printingTransparent/customized PackagingCartons/customized OEM/ODMAccepeted MOQ1000KG Usagegarment FeatureHigh durability, eco-friendly, compression resistance AdvantageCompetitive price, consistent quality, 24 hours online service

•PET film transparency •PET film durability •PET film recyclability •PET film blister packaging •PET film tableware

Material: PP Thermal formed sheet Thickness 0.25-0.9mm/customization Size: 300mm/Customization GRADE: Food grade film color: black/white/ customization location: china usage :for food tray ,mircronwave food container

Material: PET Printable sheet Thickness 0.012mm/customization Size: 100mm/Customization GRADE: Food grade film color: transparent/white/ customization location: china usage :for food tray plant tray

Material: PCR PET Printable sheet Thickness 0.012mm/customization Size: 100mm/Customization GRADE: Food grade film color: transparent/white/ customization location: china usage :for food , FOR decoration

Material: PET Printable sheet Thickness 0.012mm/customization Size: 100mm/Customization GRADE: Food grade film color: transparent/white/ customization location: china usage :for food tray plant tray

Material: BOPET Printable sheet Thickness 0.012mm/customization Size: 100mm/Customization GRADE: Food grade film color: transparent/white/ customization location: china usage :for food tray plant tray