News

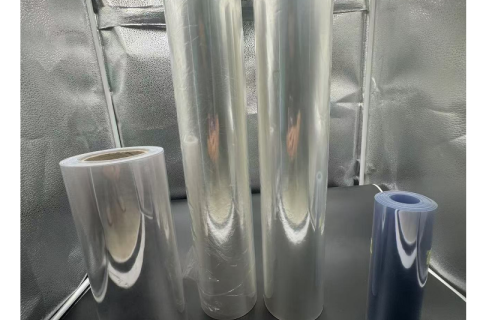

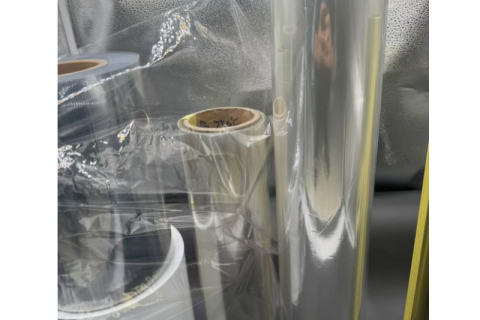

Material: pet film Thickness 0.015mm-customization Size: 100-Customization capacity: Satisfied color: white/ clear customization location: china

MATERIAL :HIPS FILM THICKNESS:0.025-0.8MM /CUSTOMIZATION WIDTH:100-1350MM/CUSTOMIZATION USAGE: THERMOFORMING BLISTER food plate,HIGHT impact part,elctronic part COLOR: transparent/ CUSTOMIZATION

material : WHITE PET FILM ROLL WIDTH SIZE: 600MM/ CUSTOMIZATION COLOR:TRANSPARENT /WHITE /CUSTOMIZATION THICKNESS: 0.015-0.8MM USAGE: for dentist disposable tray, food plate meat plate ,fruit tray

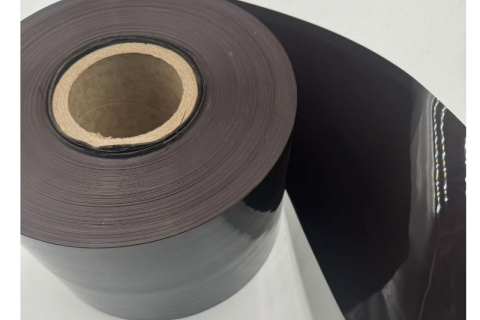

Applications of Brown PVC Film in Pharmaceutical Packaging Brown PVC film is widely used in the packaging of various types of pharmaceuticals, including tablets, capsules, powders, and liquids. It is suitable for both over-the-counter and prescription medications, as well as for generic and branded drugs.

Material: BOPP film width:100-800mm customization thickness:10-75 mic color:transparent /customization usage: cigarette package food protection,book paper cover lamination

material: disposable PLA cornstarch size:240*190*50mm usage : food tray, takeout plate,

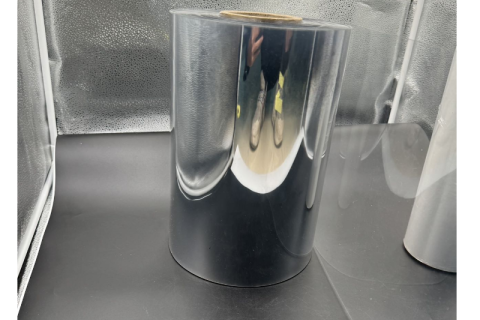

ITEM:TL-PVC-0047 Thickness:0.008-2MM Width:100-1350MM color:white blue red orange black customization Roll core:3-7” feature:Water proof Usage:Color sheet, deco film,cover film capability:5000TON/MONTH Sample:Free less than 10KG

Transparent Biaxially Oriented Polypropylene (BOPP) film has become an essential material in various industries due to its unique properties and versatility. This article will explore the extensive applications of transparent BOPP film in different fields, including food packaging, stationery, tobacco, and gift packaging. We will discuss its advantages, manufacturing process, and future prospects.

In the world of materials and printing, PVC printable film stands out as a versatile and remarkable product with a wide range of applications. From advertising and signage to personal projects and creative endeavors, this material has proven to be an invaluable asset.

In today's world of design and decoration, colored PVC film has emerged as a highly versatile and innovative material that is transforming the way we think about aesthetics and functionality. From creating stunning colored walls in interior design to enhancing the beauty of lampshades and serving as an essential tool for color selection in the form of color cards, colored PVC film is making its mark in various fields.