News

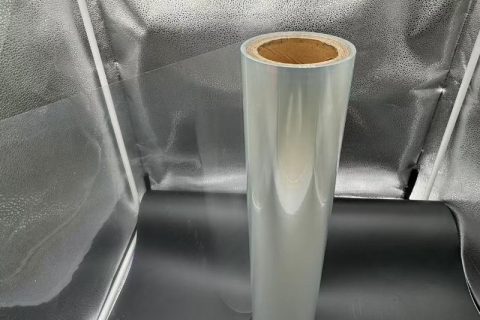

Material: BOPET Printable sheet Thickness 0.012mm/customization Size: 100mm/Customization GRADE: Food grade film color: transparent/white/ customization location: china usage :for food tray plant tray

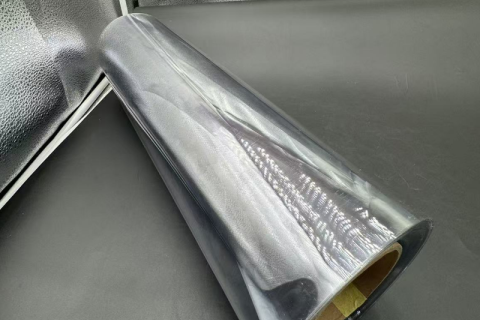

Material: PET roll Thickness 0.25 mm/customization Size: 100mm/Customization GRADE: Food grade film color: transparent/white/ customization location: china usage :for food tray ,container

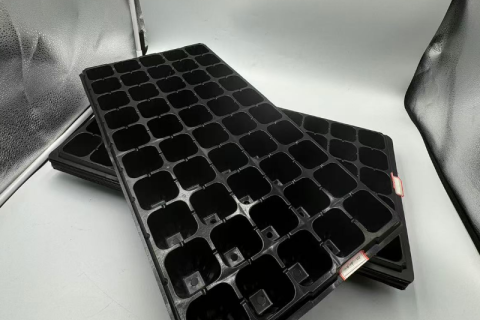

Material: PP Thermal formed sheet Thickness 0.25-0.9mm/customization Size: 300mm/Customization GRADE: Food grade film color: black/white/ customization location: china usage :for food tray ,mircronwave food container

Material: PP Thermal formed sheet Thickness 0.25-0.9mm/customization Size: 300mm/Customization GRADE: Food grade film color: black/white/ customization location: china usage :for food tray ,mircronwave food container

Material: PS Thermal formed roll Thickness 0.25-0.9mm/customization Size: 300mm/Customization GRADE: Food grade film color: black/white/ customization location: china usage :for food tray , food container,planting tray

Material: PE protection sheet Thickness 0.012mm/customization Size: 100mm/Customization GRADE: Food grade film color: transparent/white/ customization location: china usage :for food tray plant tray

Material: PLA sheet Thickness 0.25mm/customization Size: 100mm/Customization GRADE: Food grade film color: transparent/white/ customization location: china usage :for food tray plant tray

Material: PS TRAY Thickness 0.18mm/customization Size: 530*275*45MM/Customization GRADE: Food grade film color: white/ customization location: china for food tray plant tray

Material: fog BOPP film Thickness 0.012mm/customization Size: 100mm/Customization GRADE: Food grade film color: transparent/white/ customization location: china usage :for food , book, paper