Exploring the Innovative Applications of PLA Film in Food Blister Packaging

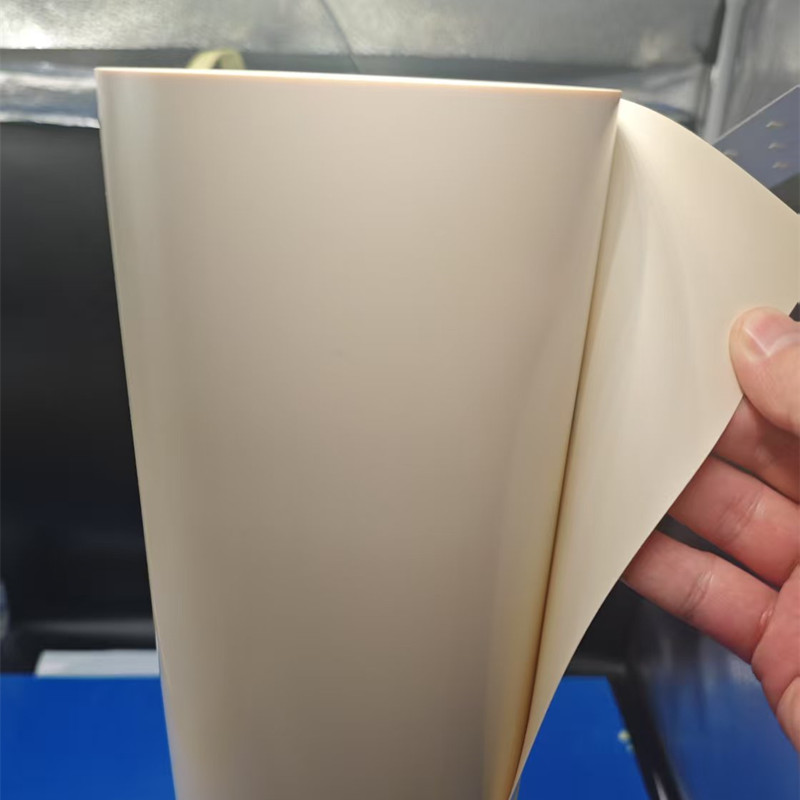

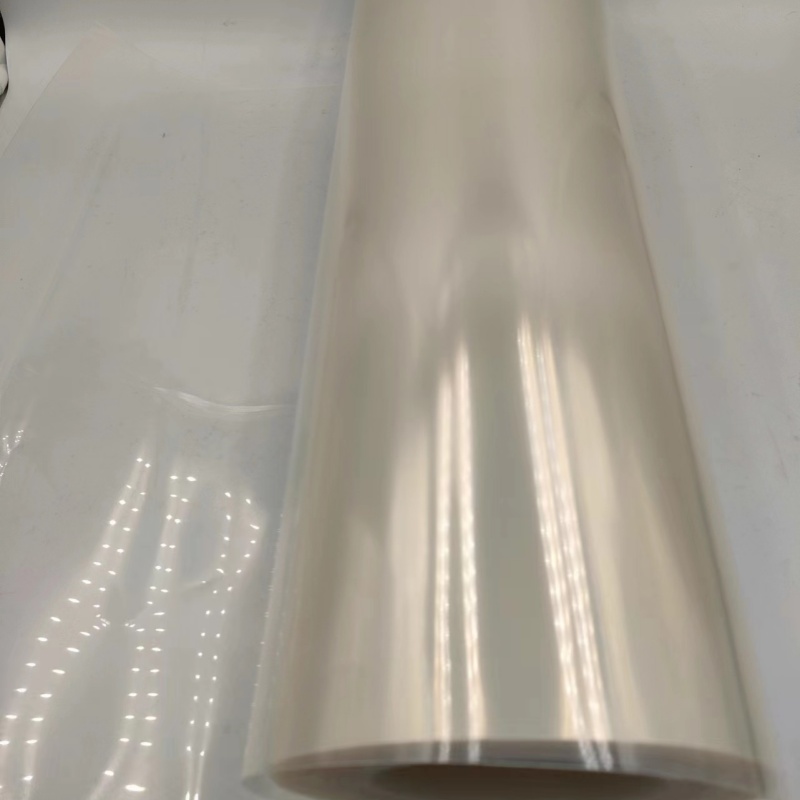

Material: PLA sheet

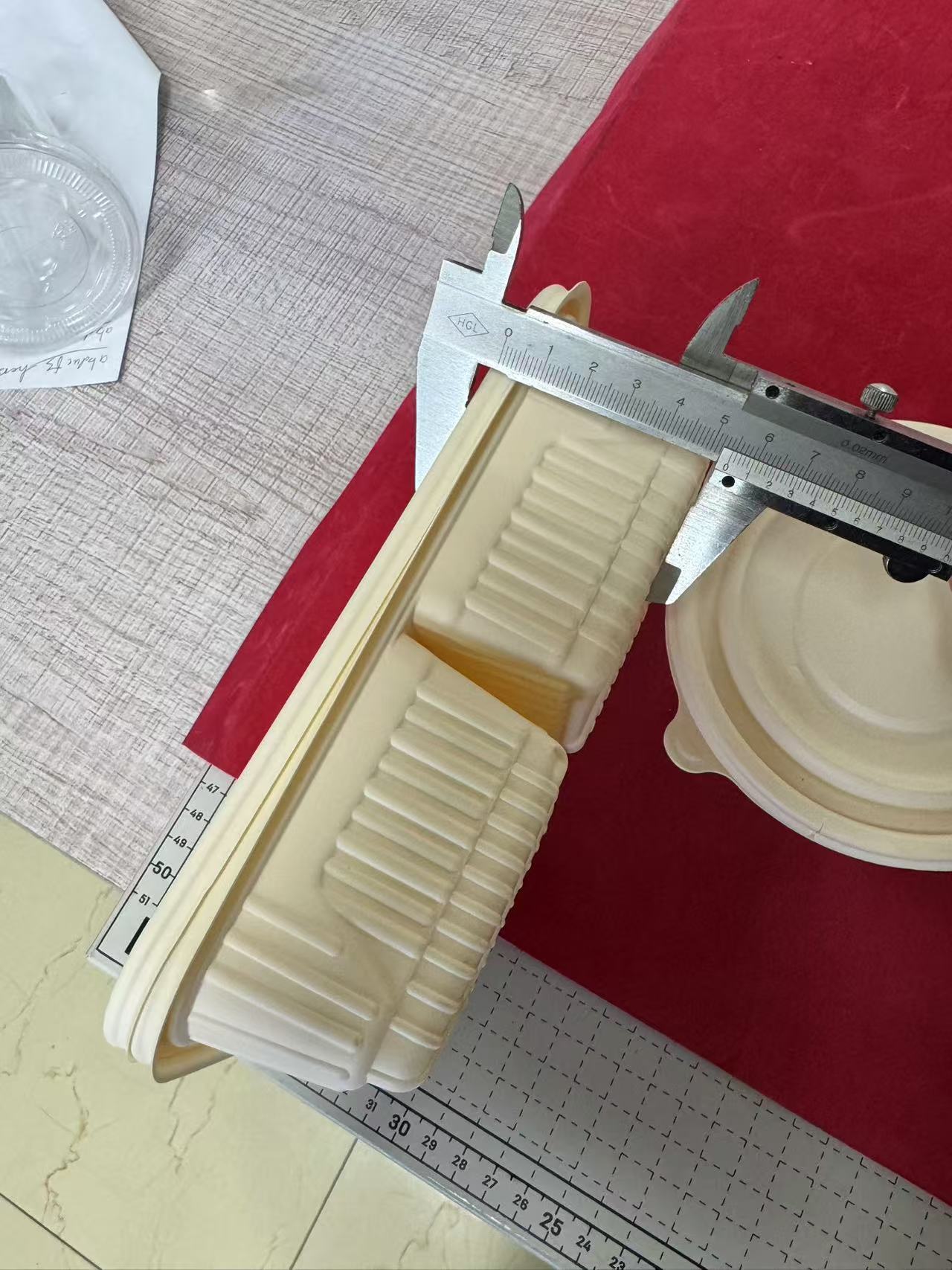

Thickness 0.25mm/customization

Size: 300mm/Customization

GRADE: Food grade film

color: transparent/white/ customization,CORN stach

location: china

usage :for food tray plant tray

- TOPLEADER

- 中国

- 15WORKING DAYS

- 5000T/M

- Information

- Video

- Download

PLA Film Application in Food Blister Packaging

I. Introduction

The right choice of the packaging material, with regard to food packaging, is considered critical. This ascertains the quality and safety of packaged foodstuffs on one hand, while it is the main cause for consumer attraction, thus important for marketing and sale of goods. In recent times, PLA or Polylactic Acid film has emerged as one of the fantastic options in food blister packaging due to increasing globalization with emphasis on environmental sustainability and consumer demand for healthier and more environmentally friendly packaging solutions.

II. Understanding PLA Film

A. Composition and Production

PLA is a biodegradable polyester that is produced from renewable resources such as corn starch, sugarcane, or tapioca. These raw materials undergo a fermentation process to eventually produce lactic acid, which in turn is polymerized into PLA. This renewable origin of PLA film differs from traditional petroleum-based plastics and reduces the carbon footprint associated with packaging production.

B. Physical and Chemical Properties

1. Transparency and Gloss

PLA film is highly transparent, just like all other conventional plastic films. The wrapped food product inside is, therefore, clearly visible and thus very appealing to consumers from the display of store shelves. The high-gloss finish further adds to the product's appeal, making it catch the eye of a consumer more frequently. For instance, PLA film transparency in the packaging of fresh fruits or artisanal chocolates allows the natural colors and textures of the food to be appealing for consumption. 2. Mechanical Strength

PLA film, while biodegradable, possesses sufficient mechanical strength to withstand the many aspects of packaging, handling, and transportation. The film can be engineered to possess suitable tensile strength, elongation, and puncture resistance. For instance, in the packaging of snack foods like potato chips, the film needs to be tear-resistant under ordinary handling conditions, and PLA film can be engineered to meet these requirements.

3.

Barrier Properties

PLA films show a moderate barrier to oxygen, moisture, and aroma. It is not exactly as impermeable as many of the traditional plastics, but its performance can be considerably improved by several techniques such as coextrusion or by the addition of barrier layers. In the case of bakery products, this film gives freshness to bread since it reduces oxygen ingestion responsible for staling and avoids moisture losses that render the bread dry.

III. Advantages of PLA Film in Food Blister Packaging

A. Environmental Sustainability

1.

Biodegradability

PLA film boasts one of the most unique advantages in relation to the packing of food in blister style: biodegradability. Under the right environmental conditions-in an industrial composting setting, for example-it can degrade into carbon dioxide, water, and biomass within a considerably short period compared to other forms of plastic packaging materials that take up to hundreds of years to decompose. The use of PLA film in food blister packaging reduces the rate at which plastic waste accumulates in landfills and oceans, making life more sustainable.

2.

Utilization of Renewable Resource

Since PLA is produced from renewable agricultural feedstocks, the production of PLA decreases reliance on fossil fuels. This not only helps save non - renewable resources but also reduces environmental pollution caused by extraction and refining of oil. Application of PLA films to packaging foodstuffs is one means by which food manufacturers can demonstrate corporate social responsibility for the environment.

B. Preservation of Food Safety and Quality

1. Non Toxicity

PLA film is nontoxic and is safe for contact with food. It will not leach harmful chemicals into the food; thus, the consumer is protected. This aspect is very significant for food products, especially food that is consumed directly or remains in contact with packaging for a long time. In the case of packaging of baby food or organic products, for instance, the nontoxic nature of PLA film gives assurance to parents and health-conscious consumers.

2.

Freshness Preservation

As mentioned, PLA film's barrier properties, along with its ability to maintain a suitable micro - environment around the food product, help to preserve the freshness, flavor, and nutritional value of food. It can prevent the entry of oxygen, which can cause oxidation and spoilage, and control moisture levels, which is essential for products like fresh produce, dairy products, and processed meats.

C. Aesthetic Appeal and Brand Image

1. Printability and Design Flexibility: PLA films allow excellent printability for food manufacturers to show real, high-quality graphics on packaging for effective communication of product information, brand identity, and marketing messages. The film may be readily coated with several techniques, including flexography, gravure, or digital printing. Besides that, flexibility in design allows the creation of unique and striking shapes in blister packaging that might make a particular product stand out in a crowded marketplace. 2. Aligns with Consumer Values

Today, in the marketplace, consumers are concerned about the environmental impact of the products they buy. Using PLA film in food blister packaging allows a brand to position itself in tune with these consumer values. This may be a way to build brand loyalty and attract environmentally-conscious consumers to give the brand a competitive advantage.

IV. Applications of PLA Film in Different Food Categories

A. Bakery Products

1. Bread and Rolls

PLA film is used to package bread and rolls on a large scale. The tendency of the film to retain moisture within it keeps the bread soft and fresh for longer. The transparency of the film also makes the product visible to the customer, which makes it more attractive. For instance, many artisanal bakeries use PLA film to package their freshly baked loaves, showing the rustic look of the bread.

2. Cakes and Pastries

PLA film prevents the loss of moisture in cakes and pastries because of its dryness, which affects their texture after being packed. It prevents odors from outside the packaging, as these may be absorbed and affect the rich flavors of baked goods. Also, the high sheen of the film will probably enhance the appearance of cakes and pastries even more.

B. Fresh Produce

1. Fruits

PLA film is highly used for fresh fruits packaging. The transparency of the film allows the consumer to see the quality of the fruits they are purchasing. while at the same time its barrier properties controls the respiration rate of the fruits hence extending their shelf life. For berries packaging for example, it prevents moisture formation in the package that results to molds while on the same side limits oxygen exposure to the fruits which leads to spoilage.

2.

Vegetables

For vegetables, PLA film protects against mechanical injury during distribution and storage. It may also maintain appropriate humidity to avoid wilting. In the case of leafy greens, this film can be designed to be permeable in order to allow the exchange of gas while still creating a barrier for moisture loss and contamination.

C. Dairy Products

1. You-gurt and Cheese

PLA usually finds its application in the packaging of yogurt and cheese products. The film in yogurt provides a leak-free seal and eliminates contamination. Besides, it enhances the freshness and flavor of the yogurt by controlling oxygen and moisture levels. For cheese products, the film can be wrapped over individual slices or blocks, protecting the cheese from drying out and preventing mold.

2. Milk and Cream

Even though milk and cream are generally packed in containers, PLA film can still be used for secondary packaging, such as shrink-wrap around multi-packs. This provides additional protection during transportation and storage and makes it easy to identify the product on the store shelves.

V. Challenges and Solutions in Using PLA Film

A. Cost-Effectiveness

1. Higher Production Costs

The current production cost of PLA film is comparatively higher than the conventional plastic film. It can be majorly reasoned out with raw material costs, complexity of the production process, and smaller-scale production as compared to traditional plastics. To this challenge, research is being done to enhance efficiency at the production stage, reduce raw material costs by identifying better agricultural practices and handling of the value chain, as well as economies of scale from increased production.

2.

Long - Term Cost - Benefit Analysis

Despite the cost being higher, food manufacturers must look into the long-term cost-benefit of PLA film. For instance, using PLA film would reduce the cost of waste disposal since it is biodegradable. The use of PLA film also improves brand value and consumer loyalty, increasing sales that can offset the higher cost of packaging.

B. Performance Limitations

1. Heat Sensitivity

PLA film has a relatively low heat resistance compared to some conventional plastics. This will therefore limit its use in high-temperature processing applications, such as in-package sterilization or microwave heating. In order to overcome this limitation, several researchers are developing heat-resistant PLA formulations by such techniques as copolymerization and addition of fillers. 2. Barrier Property Enhancement

Although PLA film has moderate barrier properties, there exist food products that require a higher degree of barrier protection. In a bid to enhance the barrier properties of PLA film, techniques being studied include co - extrusion with other polymers, the application of barrier coatings, or the use of nanocomposites.

VI. Future Trends

A. Technological Innovations

1.

Some current studies are targeted at the development of new PLA-based materials with improved properties, in particular, preparation of PLA copolymers and blends with other biodegradable polymers or using nanotechnology that reinforces mechanical, barrier, and thermal properties of the film.

2.

Integration with Smart Packaging

There is a growing trend towards the integration of smart packaging features into PLA film. This may be in the form of incorporating sensors to monitor the freshness of the food product such as oxygen or moisture sensors or possibly time - temperature indicators to advise the consumer about the storage history of the product.

B. Market Expansion

1. Increasing Consumer Demand

As eco-conscious consumers continue to increase, the demand for food products packaged in PLA film will also continue to increase, hence forcing more food manufacturers to start the usage of PLA film in their packaging. This will expand the market.

2.

Industry Collaboration

Close collaboration by the food industry, packaging manufacturers, and researchers will help to overcome such challenges as cost and performance limitations associated with PLA film. This could mean the development of even more effective solutions and wider diffusion of PLA film in food blister packaging.

VII. Conclusion

In these areas, PLA films can potentially make valuable contributions that might meet these two increasing pressures created by packaging onto environmental and aesthetic grounds, thus dealing with food safety-related concerns, given all those challenges-notably economic feasibility and multiple performances limitations-much more are well expected in those areas to witness further development for solutions in the next few years. Due to continuous rise in the demands of eco-friendly packaging, consumer demand is now calling for a massive importance of PLA film in food packaging industries as part of the sustainable future concerning both the food industry and the environment.

Within 15-20 days after received payment...more