PLA Biodegradable Corn Starch Containers: Revolutionizing Food Packaging

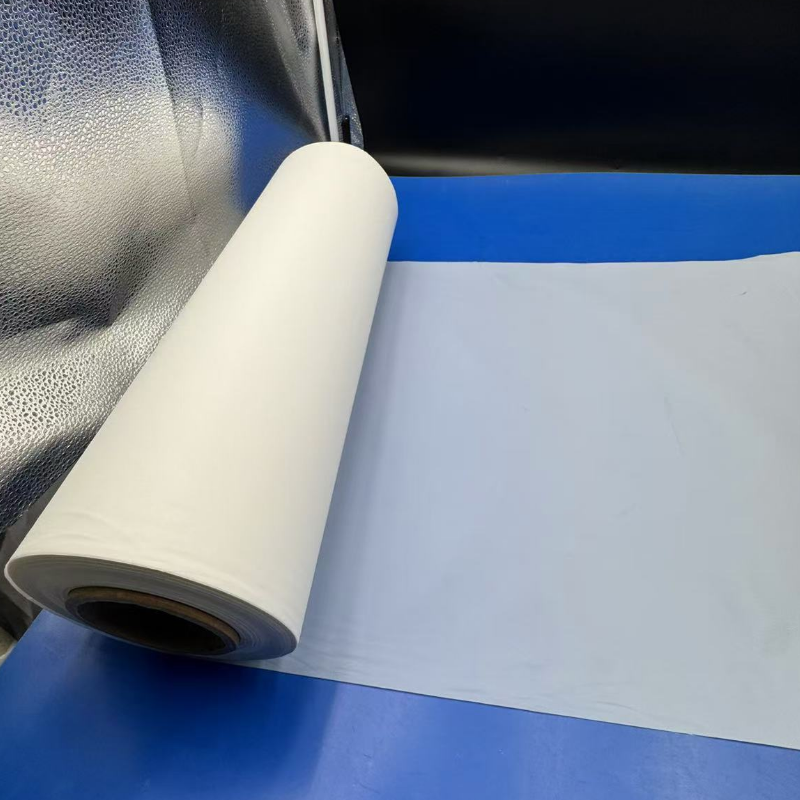

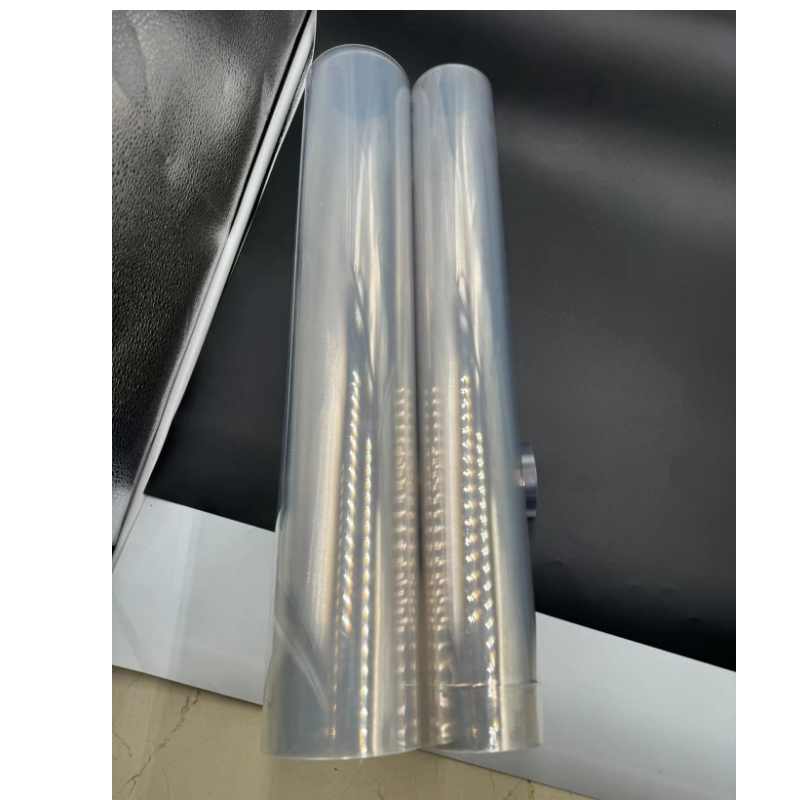

Material: PLA Printable sheet

Thickness 0.25mm/customization

Size: 100mm/Customization

GRADE: Food grade film

color: transparent/white/ customization

location: china

usage :for food

- TOPLEADER

- 中国

- 15WORKING DAYS

- 5000T/M

- Information

- Video

- Download

PLA Biodegradable Corn Starch Containers: Revolutionizing Food Packaging

Introduction

Functionality, safety, and sustainability-perhaps the Holy Grail in quest-the most overriding challenge that the food packaging industry faces in these environmentally conscious times. Among the myriads of solutions, PLA derived from corn starch stands out as a beacon of hope. PLA biodegradable cornstarch boxes have started changing the face of food packaging by offering a workable, eco-friendly alternative to conventional petroleum-based plastic.

Emergence of PLA

Polylactic Acid, commonly referred to as PLA, is one of the types of bioplastics sourced from renewable resources such as corn starch, sugarcane, or even cassava. It is produced through a fermentation process from these agricultural produces for lactic acid production, which is then polymerized into PLA. As opposed to normal plastics, that take hundreds of years to decompose, the material is finding increased usage because it is either biodegradable or compostable under industrial conditions.

PLA for Food Packaging: A Close-Up

Material Properties:

Biodegradability: PLA packaging boxes decompose under specific composting conditions into water, carbon dioxide, and biomass, which can bring landfill waste to a minimum level.

Strength and Durability: While being ecologically friendly, PLA containers boast mechanical properties no worse than traditional plastics, able to stand up to the demands of food packaging, including resistance to grease and moisture.

Thermal Stability: PLA has a melting point of approximately 150-160°C, which is sufficient for a wide range of food products that do not require processing or storage at high temperatures.

Food Safety:

Non-toxic: PLA is approved by the FDA for food contact and will not leach harmful chemicals into food products, unlike some plastics that can release chemicals such as BPA.

Barrier Properties: PLA can be engineered to provide excellent barriers against oxygen and moisture, which is critical in extending the shelf life of perishable goods.

Environmental Impact:

Carbon Footprint: PLA is typically produced to cause less carbon footprinting, particularly those derived from agricultural waste, compared to the standard plastics.

End-of-Life: Unlike in petroleum-based plastics, it does not account in microplastic pollution since these degrade into natural lactic acid or monomers barely found in biological systems.

Food Industry Applications

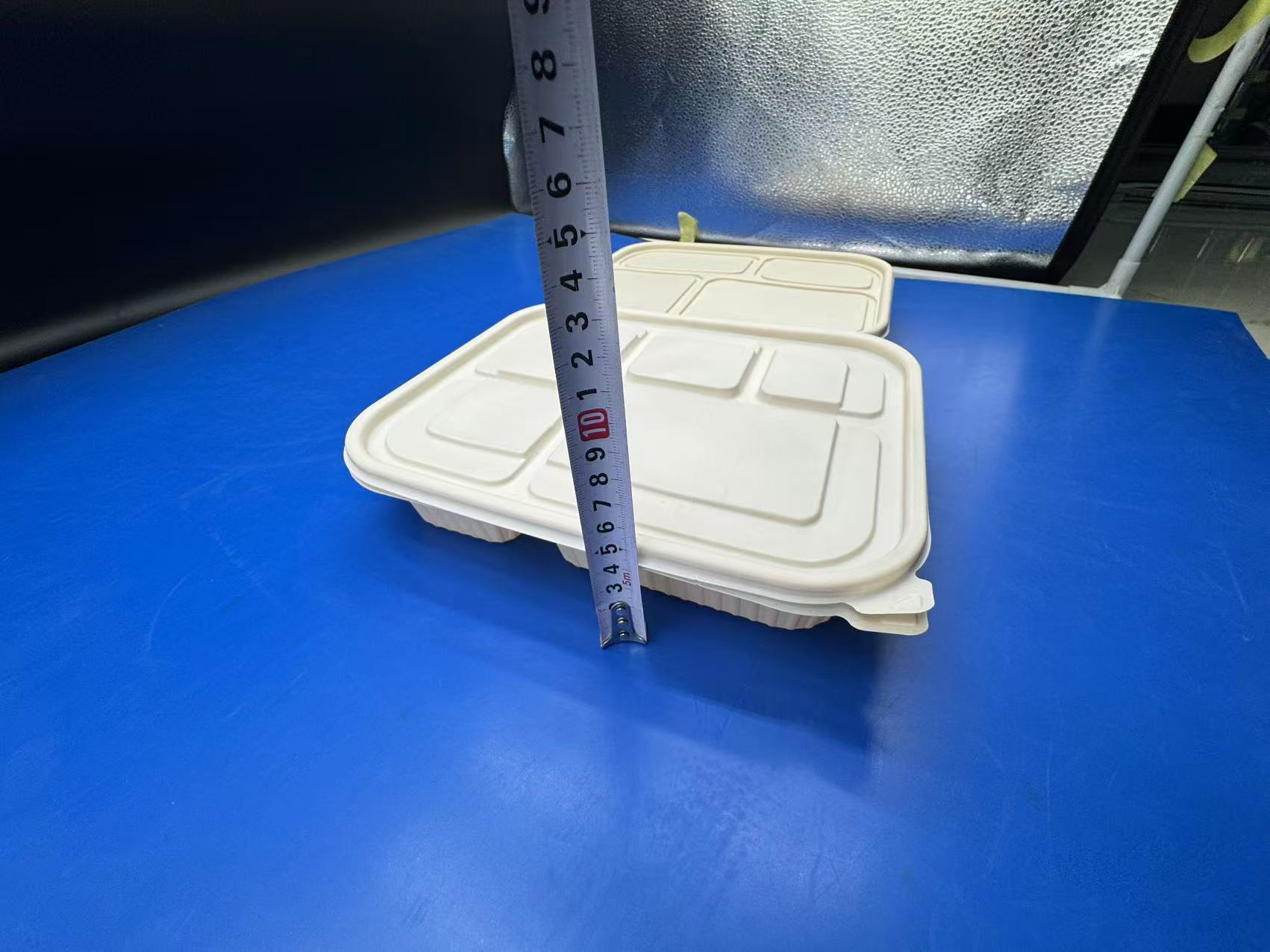

Fast Food and Takeaway:

PLA boxes can be increasingly implemented in takeaway food as an ecologically friendly method where plastic or Styrofoam used to be the answer. These are very handy with regards to cold or cold-temperature food; this makes sure that with every meal served on the go, the ecological strain is less.

Fresh Produce:

PLA packagings not only contribute to keeping fruits and vegetables fresh but also try to reduce guilty feelings caused by plastic packaging in general.

Gourmet and Catering:

Upscale restaurants and caterers are increasingly using PLA for its aesthetic appeal, along with its eco-credentials. Available in a range of shapes and sizes, PLA can complement the most discerning dining experience with its commitment to sustainability.

Challenges and Considerations

Despite the benefits, PLA does come with some limitations:

Temperature Sensitivity: PLA cannot be used for hot foods because it deforms or melts at temperatures above its glass transition temperature.

Composting Infrastructure: Effective degrading requires industrial composting facilities, which are not universally available, hence, a challenge in disposal.

Cost: PLA can be more expensive initially than traditional plastics, although economies of scale could address this over time.

The Future of PLA in Food Packaging

The future of PLA corn starch boxes in food packaging looks bright, with innovations continuing to make this material even better. These include blending with other biopolymers for improved heat resistance and the incorporation of natural antimicrobial agents that would help extend the life of the food beyond what PLA packaging currently offers.

Research and Development:

Development of new corn varieties to provide higher yield and quality PLA.

Development of PLA composites for wider applications in heat-resistant packaging.

Legislation and Market Trends:

Increasing regulations around single-use plastics drive the adoption of PLA.

Consumer demand for sustainable packaging solutions is to blame for driving companies to PLA.

Conclusion

PLA biodegradable corn starch boxes are not a replacement but a change in paradigm regarding food packaging. They epitomize the ways in which businesses can actually make a positive difference to their environmental footprint without compromising on quality and safety. As technology and infrastructure continue to evolve, the role of PLA within the food industry is likely to grow and usher in a new era of sustainable consumption and production.

The given research on PLA packaging of foodstuffs brings forth an overview of the present benefits and challenges faced while opening a wide vista for future innovations that will go a long way in ushering sustainability into everyday life.

Within 15-20 days after received payment...more