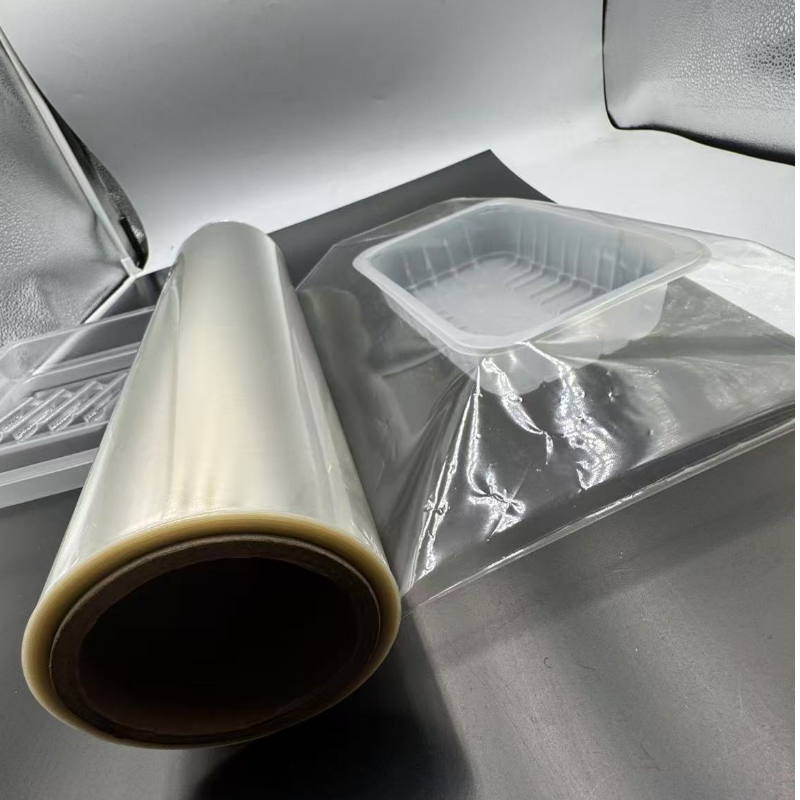

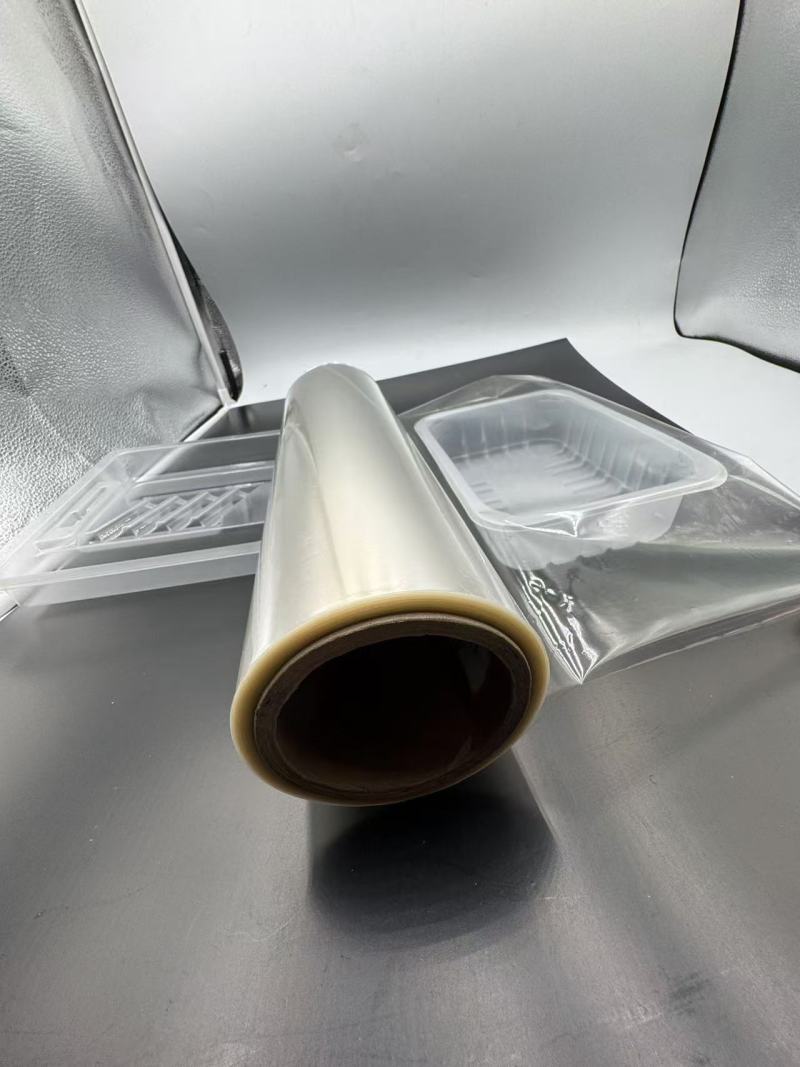

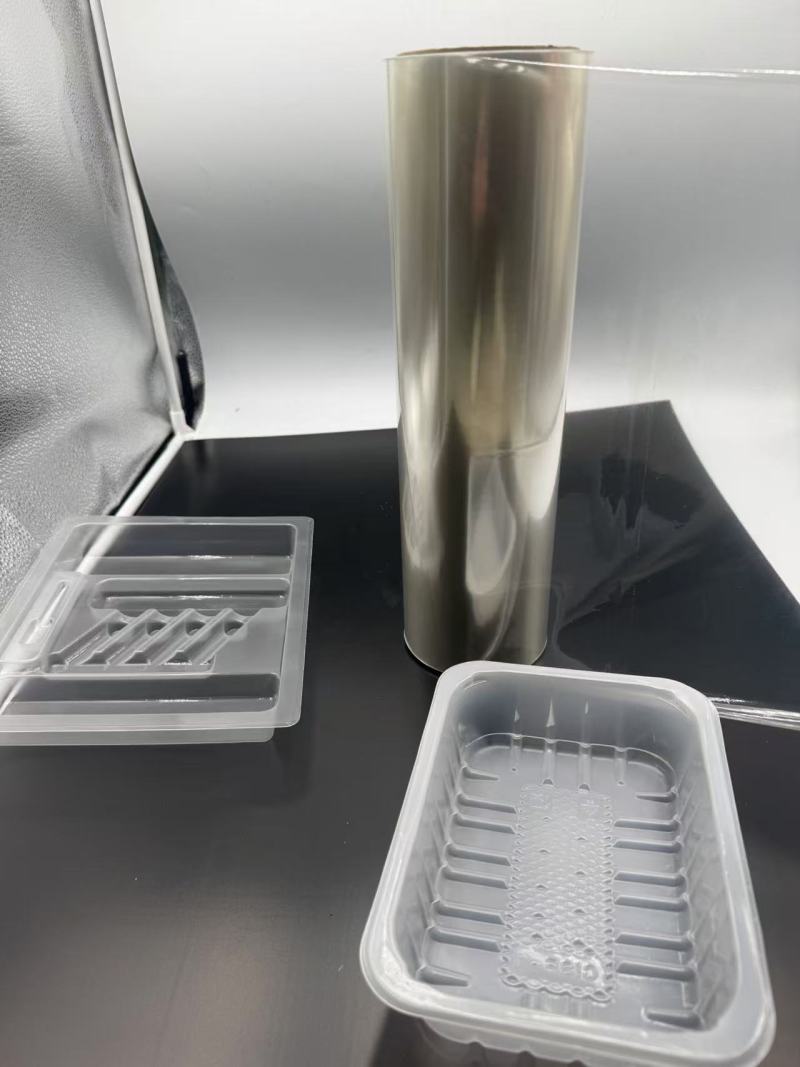

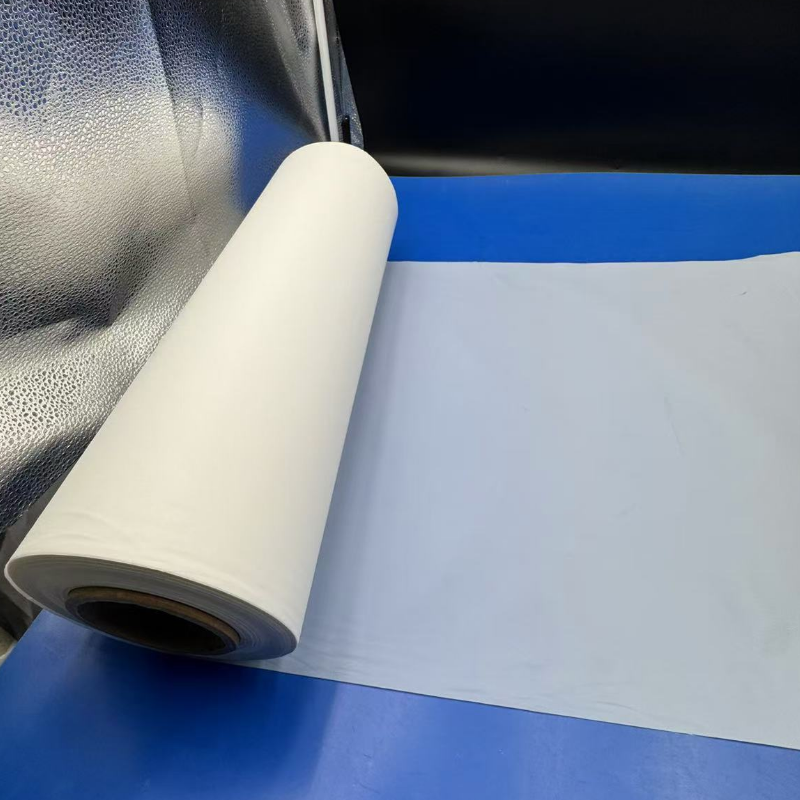

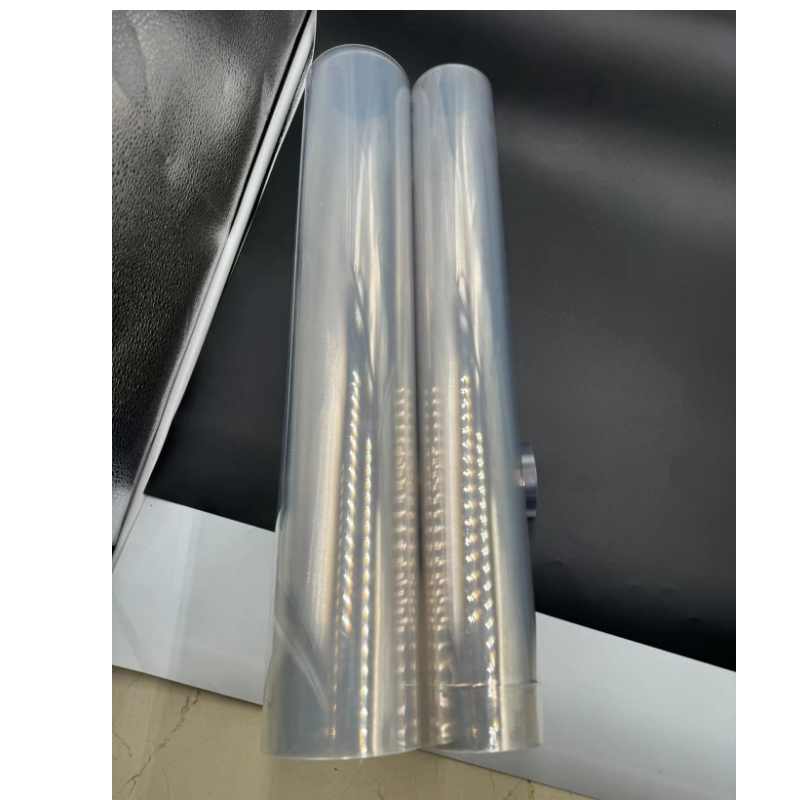

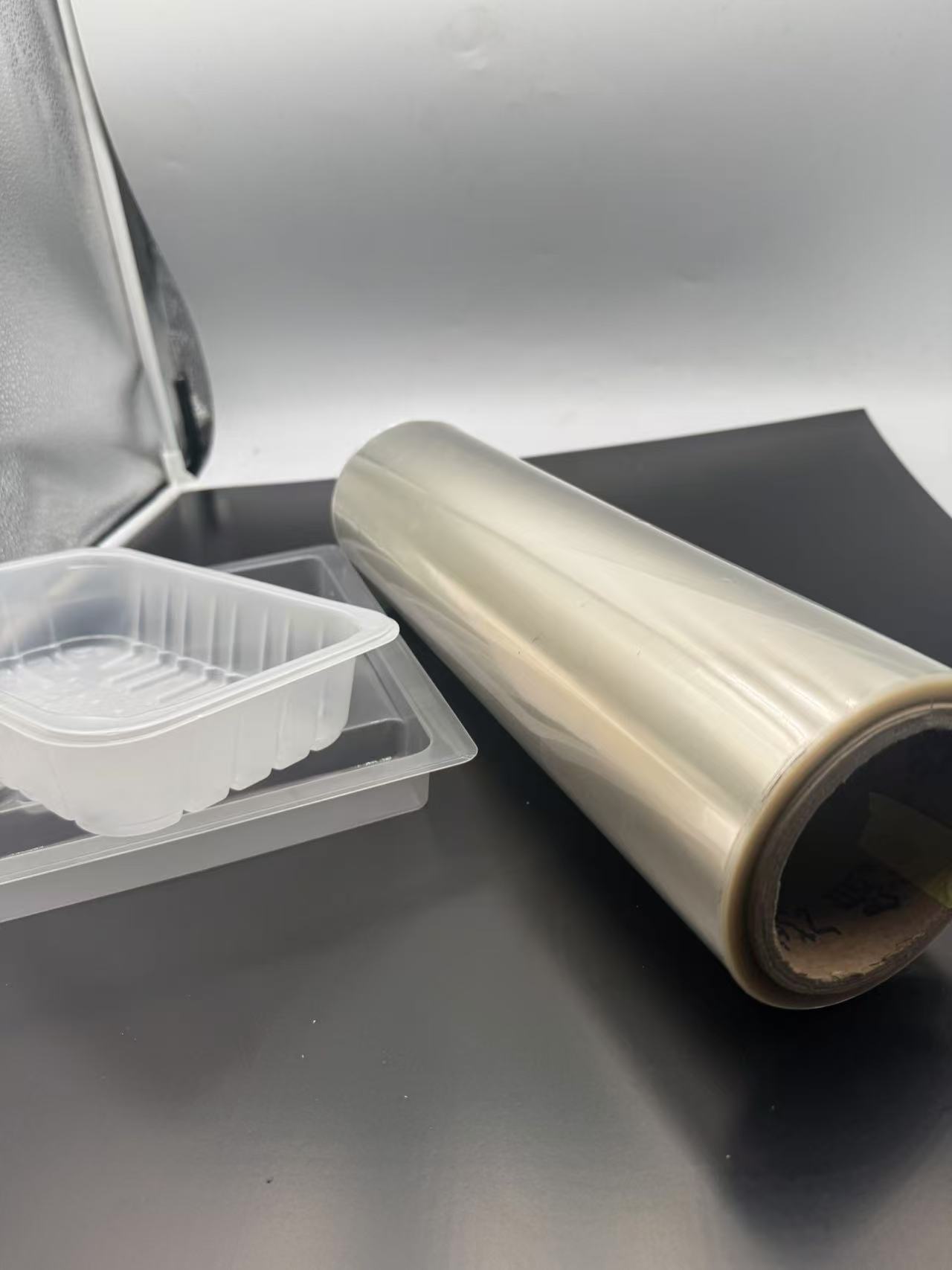

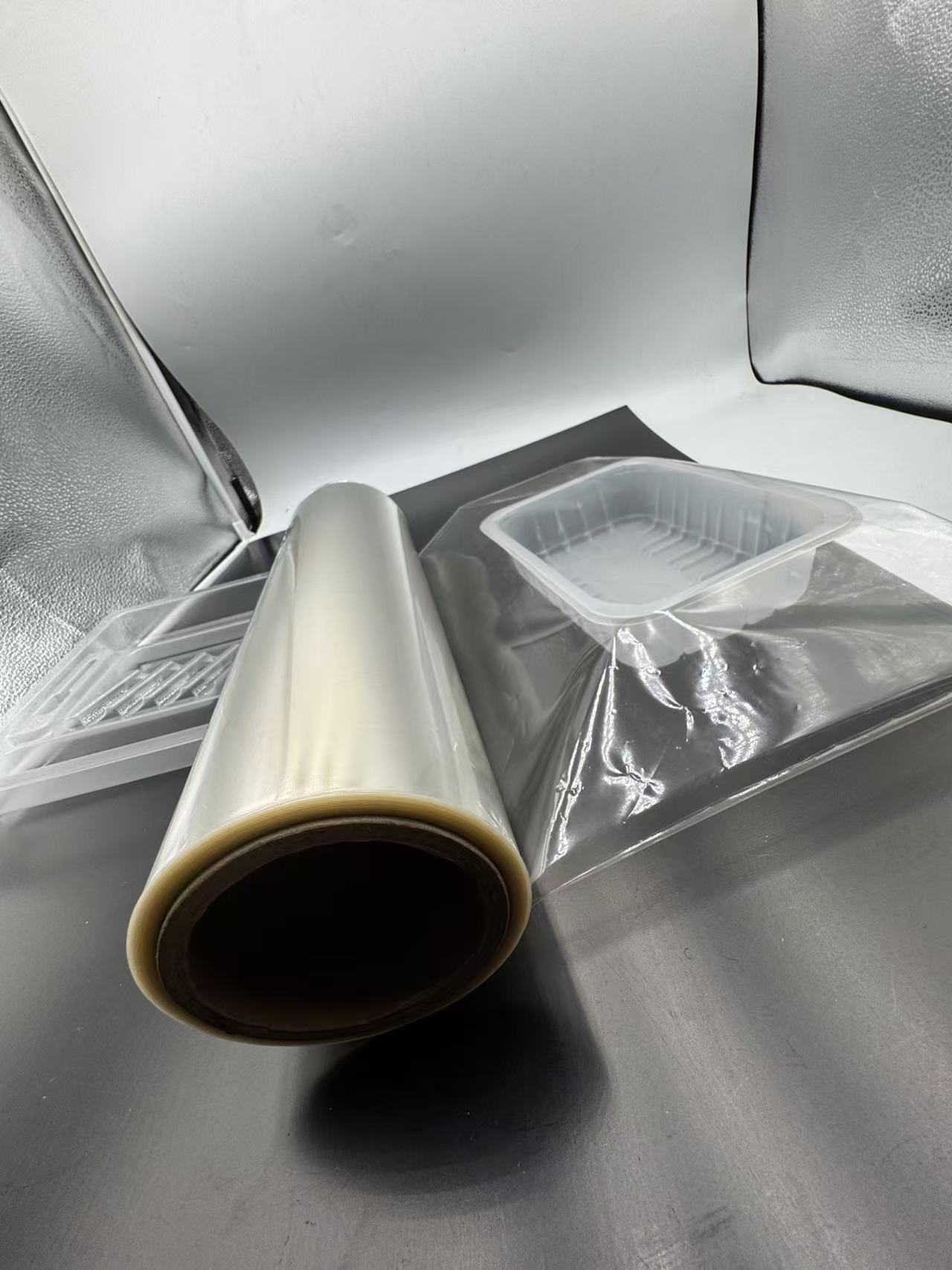

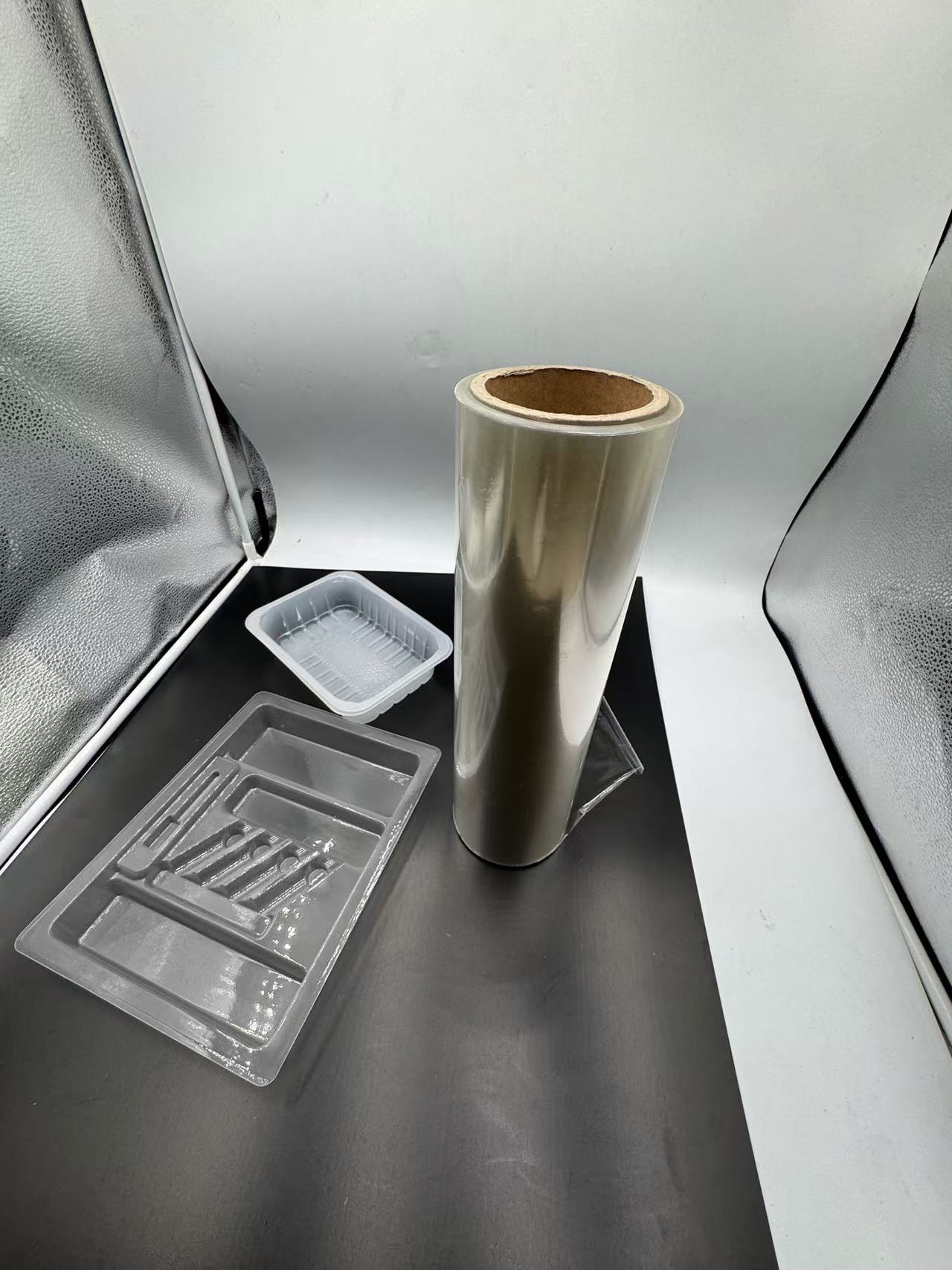

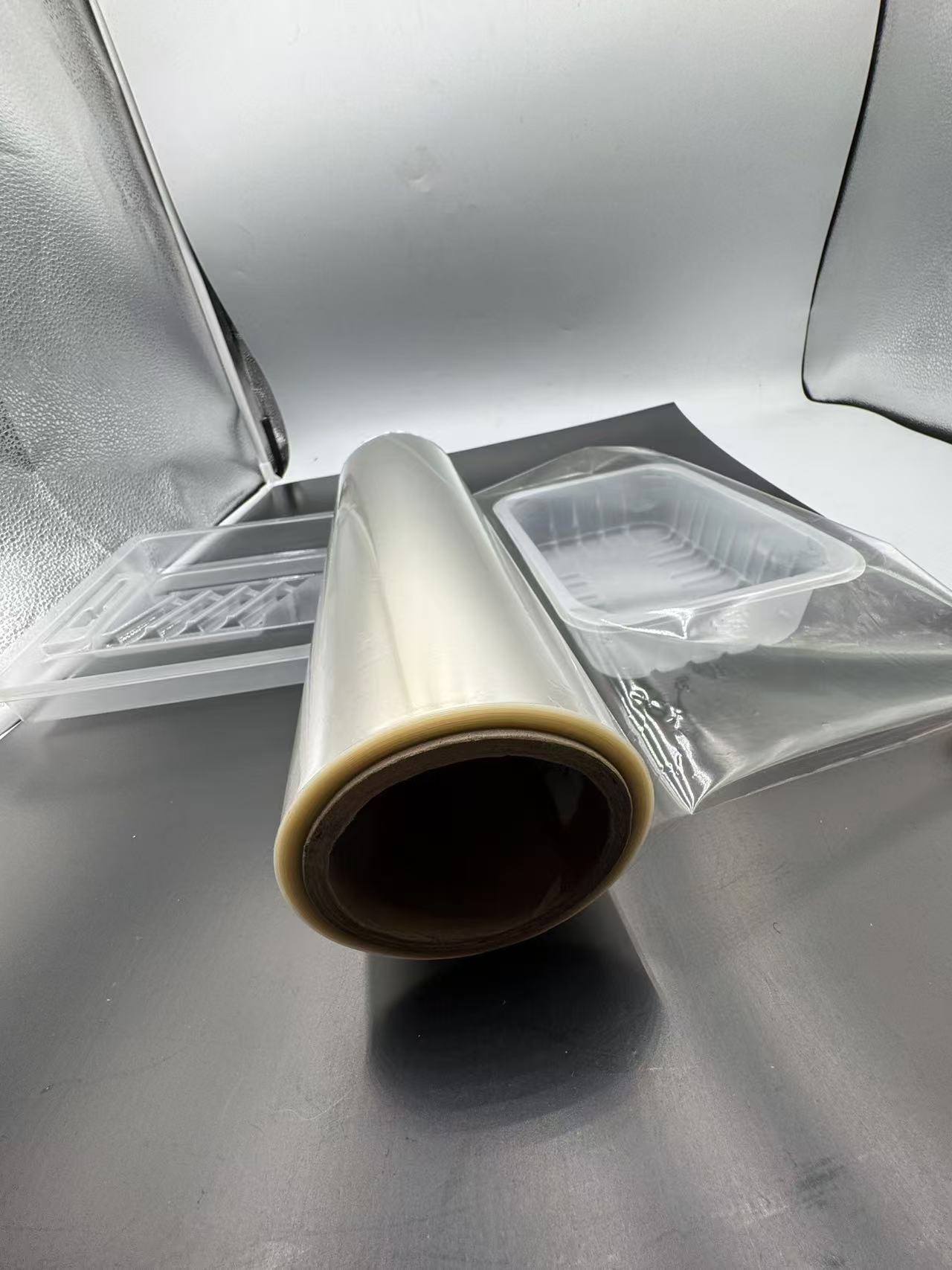

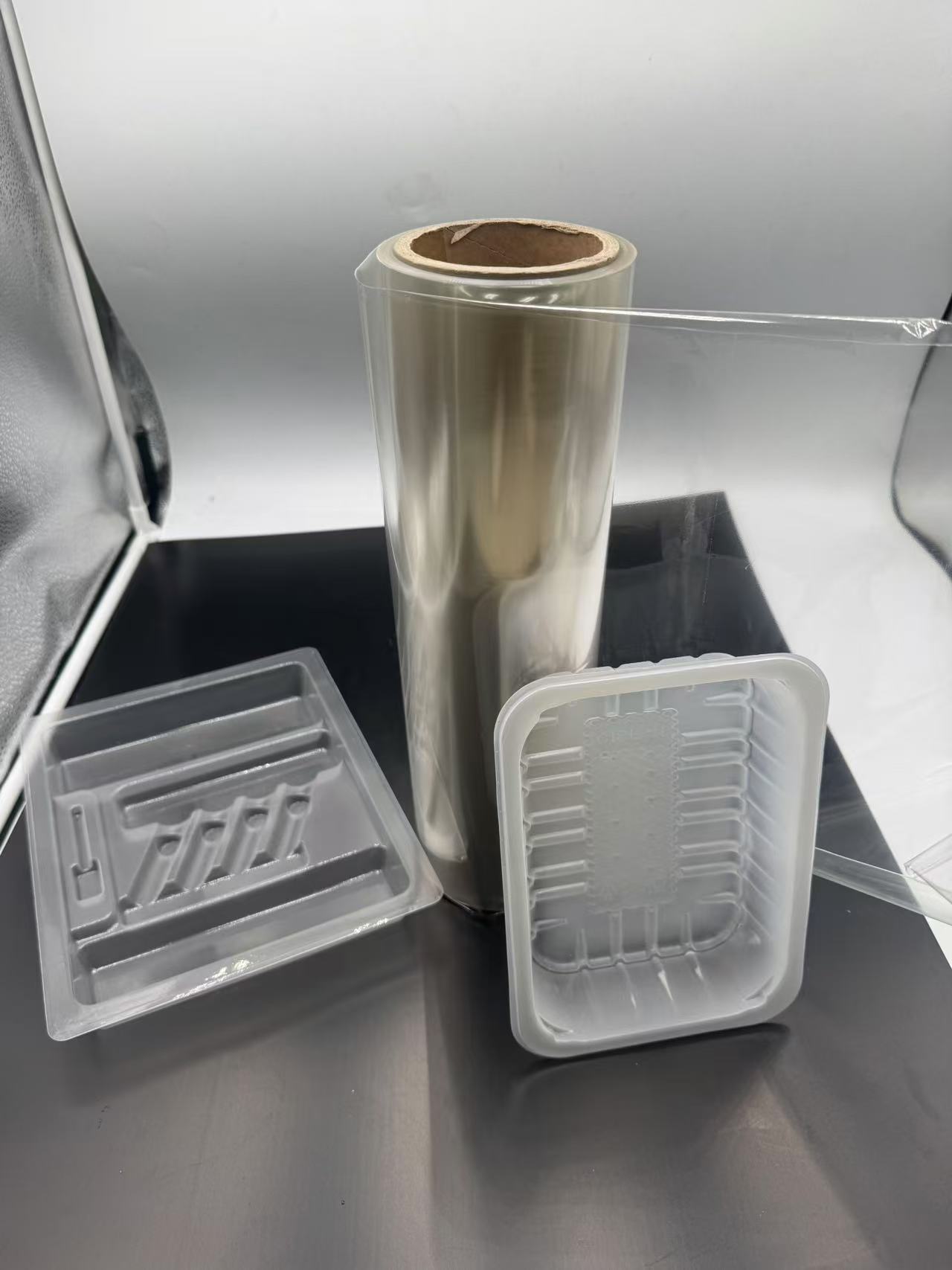

814PLA FILM for food packaging, food box cover

Material: PLA ROLLS

Thickness 0.012mm/customization

Size: 100mm/Customization

GRADE: Food grade film

color: transparent/white/ customization

location: china

usage :for food tray plant tray

- TOPLEADER

- 中国

- 15WORKING DAYS

- 5000T/M

- Information

- Video

- Download

Ⅰ. Introduction to Degradable Transparent Films

Plastics have become an indispensable part of our daily lives, bringing convenience in various aspects. However, the plastic waste they generate has caused tremendous harm to the ecological environment and poses a significant threat to human health.

The non-biodegradable nature of plastic garbage leads to the accumulation of a large amount of plastic waste in the environment, resulting in serious problems such as white pollution and the so-called "white cancer" in agriculture.

To address these environmental issues, the development of degradable transparent films has emerged as an urgent need. Scientists have been working hard to create a new generation of sustainable plastic alternative materials. A recent breakthrough in this field comes from the team of Academician Yu Shuhong of the University of Science and Technology of China. They have successfully developed a kind of super-strong, super-tough, and transparent high-performance sustainable nacre-inspired composite film.

This remarkable film features a dense "brick-fiber" structure similar to that of nacre. By filling the internal pores of the film to ensure light transmission and scattering the light passing through the interface of nanosheets and cellulose to guarantee optical haze, it can simultaneously achieve a high transparency of over 73% and a high optical haze of more than 80% within the visible spectral wavelength range of 370-780 nanometers.

Not only does this film possess high transparency and haze, but it also demonstrates excellent mechanical properties. Its strength and toughness are respectively more than 6 times and 3 times higher than those of commercial PET plastic films. The nanofiber three-dimensional network and the "brick-fiber" structure help to uniformly disperse stress, avoid stress concentration, effectively inhibit crack propagation, and enhance the hydrogen bond density between the fibers within the material, promoting fiber slippage during the film stretching process, thereby endowing the material with both high strength and high toughness.

Furthermore, as a bio-based sustainable material, this film shows outstanding thermal stability. Its coefficient of thermal expansion is as low as approximately 3 ppm K-1, meaning that for every 100°C change in temperature, the size change is only three ten-thousandths. Compared to plastic films that tend to soften and deform easily at high temperatures, this film can maintain its structure and performance stability even at 250°C, presenting superior service performance in extreme environments.

In addition, this bionic film material can be completely biodegraded under natural conditions, overcoming the difficulty of degrading discarded plastics. It meets the requirements of optical transparency, flexibility, low cost, and dimensional stability at high and low temperatures for the substrate materials of flexible electronic devices, and is green and pollution-free throughout its entire life cycle.

The research and development of this degradable transparent film is of great significance. It not only offers a potential solution to the plastic pollution problem but also has wide-ranging applications in various fields. For example, in the packaging industry, it can be used for food packaging, such as sealing lunch boxes, providing both good transparency and safety. Its excellent mechanical properties ensure the integrity and protection of the packaged items. Moreover, in environmental protection packaging, it helps reduce the environmental impact caused by traditional plastics.

In the field of flexible electronics, it shows promising potential as a substrate. Its superior optical, mechanical, and thermal properties make it an excellent alternative to traditional plastic substrates. It can be fabricated into large-sized samples, maintaining good flexibility and electrical conductivity even when bent. This allows for the design and production of more flexible and reliable electronic devices.

Overall, the emergence of degradable transparent films represents a significant advancement in the search for sustainable materials. Their unique characteristics and wide application prospects provide new possibilities for a more environmentally friendly and sustainable future.

Ⅱ. Characteristics of Degradable Transparent Films

A. Optical Properties

Degradable transparent films possess unique optical properties that set them apart from traditional plastic films. These films can achieve a high level of transparency while also exhibiting a certain degree of optical haze. This is made possible by their special microstructure. For example, the "brick-fiber" structure, similar to that found in nacre, plays a crucial role. The pores within the film are filled to ensure light transmission, while the interface between the nanosheets and cellulose scatters the light, thereby guaranteeing the optical haze. As a result, within the visible spectral wavelength range of 370-780 nanometers, these films can simultaneously attain a high transparency of over 73% and a high optical haze of more than 80%.

In contrast, traditional polymer plastic films, with their homogeneous structure, allow light to pass through easily but have difficulty scattering it. This makes it challenging for them to possess such a combination of high transparency and haze. The optical characteristics of degradable transparent films offer significant advantages in various applications. In light-emitting devices or displays, for instance, the ability to scatter light effectively helps to achieve a more even light distribution. This not only improves the visual experience for the user but also enhances the overall performance and efficiency of the device. By optimizing the light management, these films can increase the proportion of transmitted light and extend the light transmission path, ultimately leading to a significant improvement in light capture efficiency.

B. Mechanical Properties

The mechanical properties of degradable transparent films are outstanding. They exhibit high strength and toughness, which are several times that of common commercial plastic films. For example, the strength and modulus of a certain type of degradable transparent film can reach 482 MPa and 15 GPa respectively, which are 6 times and 3 times higher than those of commercial PET plastic films. This high strength and toughness enable the film to be folded into various shapes without obvious damage, even after multiple folding and unfolding operations.

The excellent mechanical properties of these films can be attributed to their nanostructure design. The nanofiber three-dimensional network and the "brick-fiber" biomimetic structure play a crucial role in this regard. These structures help to disperse stress uniformly, preventing stress concentration and effectively inhibiting crack propagation. Additionally, the fiber thinning effect can increase the hydrogen bond density between the fibers within the material, promoting fiber slippage during the film stretching process. This unique combination of structural features endows the material with both high strength and high toughness, making it suitable for a wide range of applications where durability and flexibility are required.

C. Thermal Stability

Degradable transparent films also demonstrate remarkable thermal stability. They possess a very low thermal expansion coefficient, typically as low as 3 ppm K-1. This means that compared to traditional plastic films, their size changes minimally with temperature variations. For example, when the temperature changes by 100°C, the size change of these films is only three ten-thousandths, while traditional plastic films may experience much more significant dimensional changes.

This excellent thermal stability allows degradable transparent films to maintain their structural and performance stability even at relatively high temperatures. In some extreme temperature environments, such as in certain industrial processes or in electronic devices that generate heat during operation, these films can still function effectively without softening or deforming. This property expands their potential applications, making them suitable for use in situations where temperature fluctuations are a concern.

D. Degradability

One of the most significant characteristics of degradable transparent films is their degradability. These films can be completely biodegraded under natural conditions, which is a major advantage over traditional plastics. The degradation process occurs through the action of microorganisms in the soil or water, or under the influence of ultraviolet rays in sunlight.

During the degradation process, the film's molecular structure is gradually broken down by the microorganisms or the ultraviolet radiation, ultimately being converted into harmless substances such as water and carbon dioxide. This biodegradability is of great significance in addressing the problem of plastic pollution. It helps to reduce the accumulation of plastic waste in the environment, minimizing the harm caused by microplastics to the ecological environment and human health. By decomposing naturally, these films do not leave behind persistent pollutants, making them a more sustainable and environmentally friendly option for various applications.

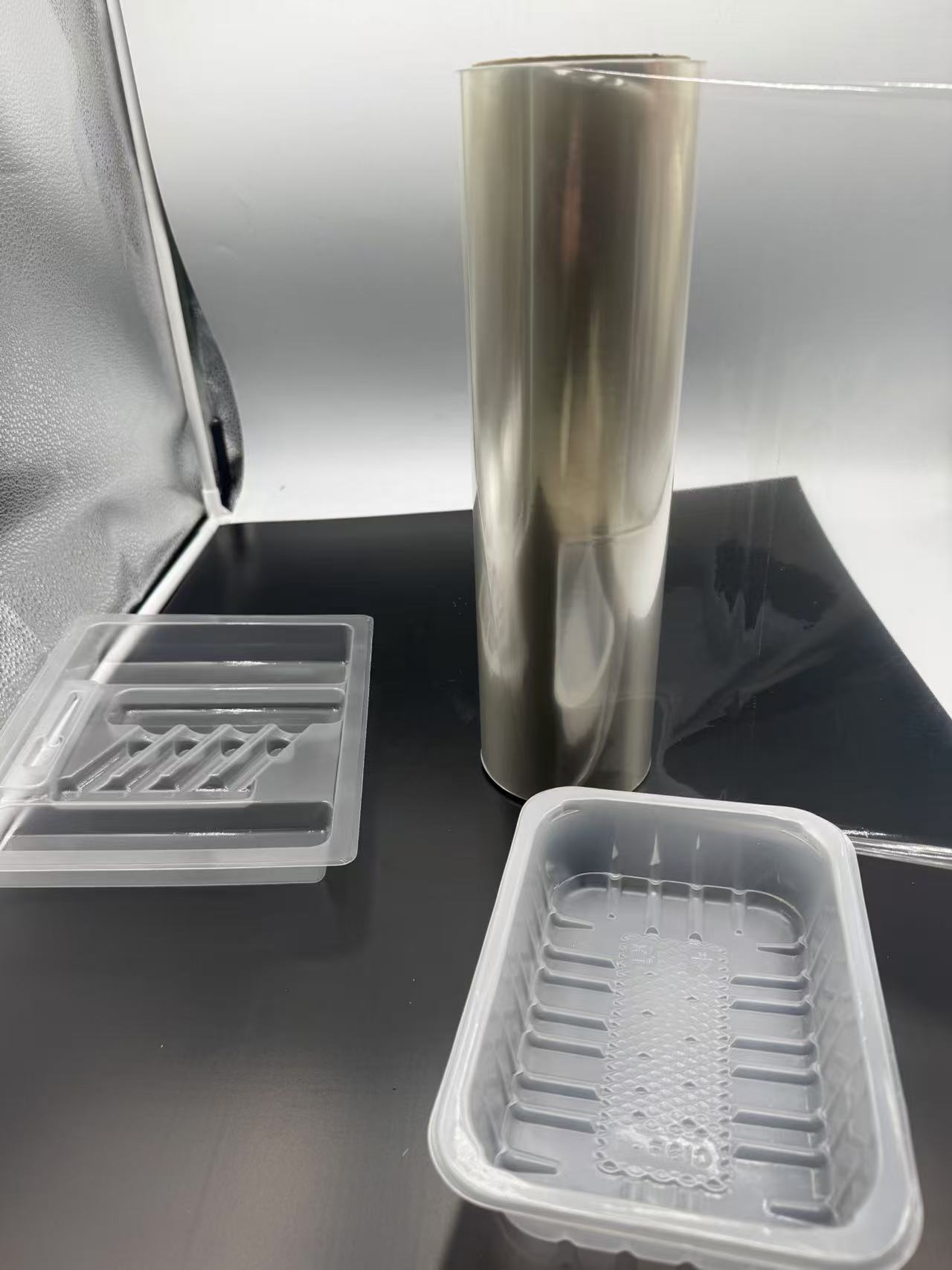

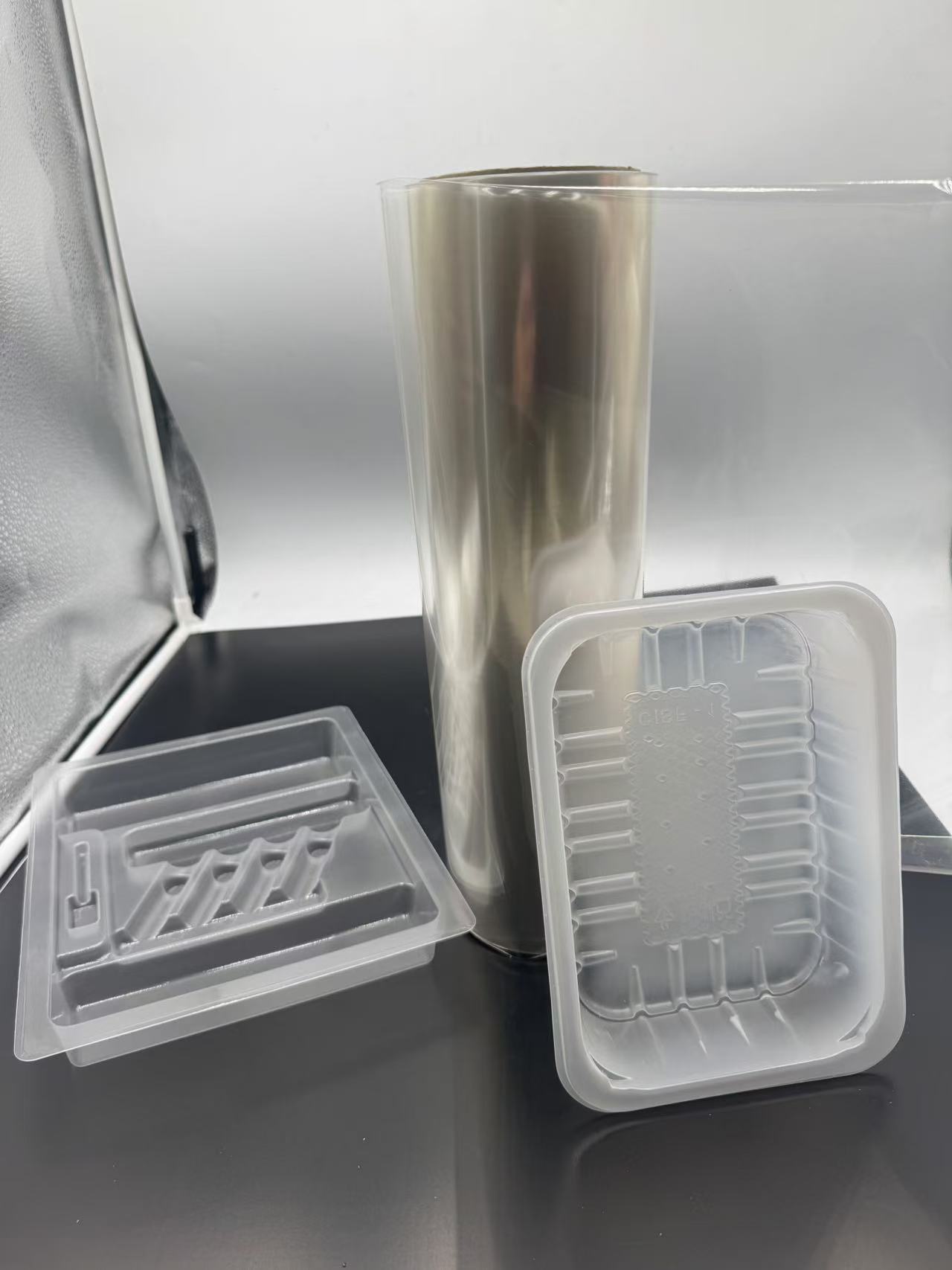

Ⅲ. Applications of Degradable Transparent Films in Food Packaging

A. Role in Sealing Food Boxes

Degradable transparent films have become a popular choice for sealing food boxes due to their excellent sealing performance. These films can effectively block air and moisture, preventing external contaminants from entering the food and ensuring its freshness and safety. For example, in the fast-food industry, many restaurants use degradable transparent films to seal their takeout boxes. The film forms a tight seal around the edges of the box, keeping the food warm and preventing it from drying out.

One of the key advantages of these films is their resistance to tearing. During transportation, food boxes may be subjected to rough handling, but the strong and durable nature of degradable transparent films ensures that they won't tear easily. This helps to maintain the integrity of the packaging and protects the food inside. Additionally, these films are often designed to be resistant to high temperatures. This means that they can withstand microwave heating without deforming or releasing harmful substances. Consumers can conveniently heat their food in the microwave without having to transfer it to another container, saving time and effort.

Several brands have recognized the benefits of using degradable transparent films for food box sealing. For instance, Company X, a leading food packaging manufacturer, has introduced a new line of degradable sealing films. These films not only provide excellent sealing and protection but also have a clear and transparent appearance, allowing consumers to see the food inside. This has improved the overall quality of their food packaging and has been well-received by both consumers and retailers. The use of degradable transparent films in food box sealing is a significant step towards more sustainable and convenient food packaging solutions.

B. As Packaging Materials for Fresh Food

In the realm of fresh food packaging, degradable transparent films play a crucial role. They are widely used to package a variety of fresh foods, including fruits, vegetables, and cooked foods. The high strength of these films provides a reliable barrier against physical damage during handling and transportation. For example, when packaging delicate fruits like strawberries or raspberries, the film prevents bruising and keeps the fruits intact.

Moreover, the antioxidant and antibacterial properties of some degradable transparent films help to extend the shelf life of fresh foods. These films can inhibit the growth of bacteria and fungi, reducing the risk of spoilage. The good airtightness of the films also helps to maintain the optimal humidity level inside the package, preventing the food from drying out or becoming soggy. This is particularly important for maintaining the crispness and texture of vegetables.

In real-life scenarios, consumers have benefited greatly from the use of these films. For instance, a busy working professional can purchase pre-cut vegetables packaged in degradable transparent films. The film keeps the vegetables fresh for several days, allowing the consumer to have healthy and convenient meal options throughout the week. This not only reduces food waste but also promotes a more sustainable lifestyle. Additionally, the transparency of the film enables consumers to easily identify the contents and quality of the food, enhancing their shopping experience.

C. In the Field of Beverage Packaging

The application of degradable transparent films in beverage packaging is also on the rise. These films are commonly used for sealing cups and bottles, especially for drinks like milk tea, coffee, and juices. Their good sealing properties ensure that the beverages remain hygienic and free from contamination. For example, in the case of milk tea cups, the film seal prevents spills and keeps the drink fresh until it is consumed.

The degradable nature of these films makes them an ideal choice for environmentally conscious consumers and businesses. As the demand for sustainable packaging grows, many beverage companies are switching to degradable transparent films to reduce their environmental impact. Some innovative designs of these films include features such as easy-peel tabs for opening the package, which enhance the user experience. Additionally, the films can be printed with attractive designs and branding information, making the packaging more appealing on the shelves.

In the coffee shop industry, for instance, many cafes now use degradable transparent films to seal their takeaway coffee cups. This not only provides a secure seal but also gives the cups a professional and modern look. The films are also compatible with recycling systems, further reducing waste. Overall, the use of degradable transparent films in beverage packaging is a positive trend that combines functionality, aesthetics, and environmental responsibility.

Ⅳ. Applications of Degradable Transparent Films in Environmental Protection Packaging

A. In General Environmental Protection Packaging

Degradable transparent films have found extensive applications in general environmental protection packaging. They are increasingly being used to replace traditional plastic packaging materials in a wide range of scenarios. For example, in the packaging of daily necessities such as shampoo bottles, soap boxes, and toothpaste tubes, these films can provide a clear and visible packaging solution while reducing the environmental impact. Their transparency allows consumers to easily see the product inside, enhancing the visual appeal of the packaging.

In the cosmetics industry, many companies are now opting for degradable transparent films to package their products. This not only meets the aesthetic requirements of the industry but also aligns with the growing consumer demand for sustainable packaging. These films can effectively protect the cosmetics from moisture, air, and light, ensuring the quality and longevity of the products.

Moreover, in the packaging of electronics and small appliances, degradable transparent films can offer protection against scratches and dust during transportation and storage. Their mechanical properties ensure that the packaged items are well-protected, while their degradability reduces the burden on the environment. Overall, the use of degradable transparent films in general environmental protection packaging is a significant step towards reducing plastic waste and promoting a more sustainable packaging industry.

B. In Agricultural Packaging

The application of degradable transparent films in agricultural packaging has shown great potential. When used as mulch films in the field, they can play multiple roles in promoting crop growth. For instance, they can effectively conserve soil moisture by reducing evaporation, ensuring that the soil remains moist for a longer period. This is particularly beneficial in arid and semi-arid regions where water is scarce.

These films also have the ability to suppress weed growth. By blocking sunlight, they prevent weeds from germinating and growing, reducing the competition for nutrients and water with the crops. Additionally, they can increase soil temperature, creating a more favorable environment for soil microorganisms. These microorganisms play a crucial role in decomposing organic matter, releasing nutrients, and improving soil structure.

Some degradable films are designed to contain essential nutrients for soil and plants. After degradation, these nutrients are released into the soil, further enhancing soil quality and contributing to agricultural production. For example, certain films may contain nitrogen, phosphorus, and potassium, which are essential elements for plant growth. This dual function of providing both physical protection and nutrient enrichment makes degradable transparent films a valuable tool in modern agriculture.

C. In Industrial Separation and Packaging

In the field of industrial separation, certain degradable transparent films with unique properties have been applied with great success. Films with selective permeability, gas barrier properties, water resistance, and hydrophobicity are being used in various industrial separation processes. In sewage treatment, for example, these films can be used to separate impurities and contaminants from the water, allowing for cleaner effluent to be discharged.

In ion extraction processes, the films can selectively allow certain ions to pass through while blocking others, facilitating the purification and concentration of specific substances. In oil-water separation, they can effectively separate oil from water, reducing the environmental impact of oil spills and industrial wastewater. In gas separation, the films can be used to separate different gases, such as carbon dioxide from other gases in flue gas, which is of great significance in reducing greenhouse gas emissions.

The advantages of using these films in industrial separation are numerous. Their small footprint allows for more compact and efficient separation systems. The high separation efficiency ensures that the desired substances are effectively separated, reducing waste and improving resource utilization. The strong specificity means that they can target specific substances with high precision, enhancing the overall effectiveness of the separation process. Additionally, the high degree of automation makes them suitable for large-scale industrial applications, reducing labor costs and increasing productivity. Overall, the application of degradable transparent films in industrial separation and packaging represents a promising solution for both environmental protection and industrial development.

Ⅴ. Other Applications of Degradable Transparent Films

A. In the Field of Medicine

Degradable transparent films have found valuable applications in the medical field, particularly as drug carriers for the development of sustained-release drugs. Their unique combination of biocompatibility, non-toxicity, swelling properties, and stability in physiological environments makes them highly suitable for this purpose.

These films can precisely decompose within a specified period and range in the body, which is crucial for controlled drug release. By encapsulating the drug within the film, the release rate can be carefully regulated, ensuring a steady supply of the medication to the target site. This not only improves the efficacy of the drug treatment but also reduces the frequency of dosing, enhancing patient compliance.

For example, in the treatment of chronic diseases such as diabetes or cardiovascular conditions, where long-term drug administration is required, degradable transparent films can be designed to release the drug slowly over an extended period. This helps to maintain a constant drug concentration in the body, minimizing the peaks and troughs associated with traditional dosing methods and potentially reducing side effects.

Moreover, in cancer treatment, these films can be used to deliver chemotherapeutic agents directly to the tumor site. The ability to control the release of the drug allows for a more targeted approach, increasing the effectiveness of the treatment while minimizing damage to healthy tissues. The biodegradability of the films ensures that they are eventually broken down and eliminated from the body without causing any long-term harm.

B. In Electronic Device Packaging

The application of degradable transparent films in packaging electronic devices is also on the rise. Their optical transparency, flexibility, and stability under different temperature conditions make them an attractive option for use as base materials for flexible electronic devices.

These films can effectively protect the internal components of the devices while meeting the requirements of optical performance and flexibility. In the production of smartphones, tablets, and wearable electronics, for instance, degradable transparent films can be used to cover the display screens, providing protection against scratches and dust while maintaining excellent visual clarity.

Some companies have already started to adopt degradable transparent films in their electronic product packaging. For example, a leading electronics manufacturer has introduced a new line of smartphone packaging that uses a biodegradable transparent film. This not only reduces the environmental impact of the packaging but also gives the product a sleek and modern look. The film's flexibility allows it to conform to the shape of the device, providing a snug fit and enhanced protection during transportation and storage.

In addition, in the field of flexible electronics, such as foldable smartphones and flexible displays, degradable transparent films offer significant advantages. Their ability to withstand repeated bending and folding without losing their optical or mechanical properties makes them an ideal choice for these innovative devices. This helps to extend the lifespan of the electronics and improve their overall performance and reliability.

Ⅵ. Challenges and Future Prospects of Degradable Transparent Films

A. Current Challenges

Despite the significant potential and advantages of degradable transparent films, they also face several challenges in their current development and application. One of the primary issues is the relatively high production cost compared to traditional plastic films. The materials and production processes used for degradable films are often more expensive, which can limit their large-scale application in some industries. For example, in the packaging industry, where cost is a crucial factor, many small and medium-sized enterprises may be hesitant to adopt degradable films due to the higher price, even though they are aware of the environmental benefits.

Another challenge lies in the standardization of degradation performance evaluation. There is currently a lack of unified and comprehensive standards to accurately measure and compare the degradation rates and degrees of different degradable films. This can lead to confusion in the market and make it difficult for consumers and businesses to make informed choices. Additionally, more research is needed to improve the long-term stability of the performance of degradable films in different environments. For instance, in some extreme weather conditions or specific application scenarios, the mechanical and optical properties of the films may be affected, and further studies are required to address these issues.

B. Future Development Directions

Looking ahead, the future of degradable transparent films appears promising, with several potential development directions. Technological innovation will continue to play a crucial role in improving the performance of these films. Scientists and researchers will focus on further enhancing their strength, flexibility, and degradation speed. This could involve the development of new materials and nanostructures, as well as the optimization of production processes. For example, the exploration of novel biodegradable polymers and the combination of different materials to achieve better performance characteristics are areas of active research.

As environmental awareness continues to grow and production technology improves, degradable transparent films are expected to find wider applications in more fields. In the packaging industry, they will increasingly replace traditional plastics, not only in food packaging but also in the packaging of various consumer products. In the field of electronics, they will be further integrated into the production of flexible and wearable devices, providing both protection and functionality. In agriculture, more advanced and efficient degradable films will be developed to meet the specific needs of crop cultivation, such as better moisture retention and weed suppression.

Overall, the development of degradable transparent films is an important step towards building a more sustainable ecological environment. With continued efforts in research and development, as well as the support of government policies and market demand, these films are likely to play an increasingly significant role in reducing plastic pollution and promoting the transition to a more sustainable future.

Ⅶ. Conclusion

In conclusion, degradable transparent films possess a unique set of characteristics that make them highly valuable in various applications. Their excellent optical properties, such as high transparency and haze, enable them to enhance the performance of light-emitting devices and displays. The outstanding mechanical properties, including high strength and toughness, ensure their durability and flexibility, making them suitable for a wide range of packaging and other applications. The remarkable thermal stability allows them to maintain their structure and performance in extreme temperature environments, expanding their potential uses. And their degradability under natural conditions addresses the issue of plastic pollution, providing a more sustainable solution.

In food packaging, they play a crucial role in sealing food boxes, packaging fresh food, and beverage packaging, ensuring food safety and freshness while reducing environmental impact. In environmental protection packaging, they are widely used in general packaging, agricultural packaging, and industrial separation and packaging, contributing to the reduction of plastic waste and the promotion of sustainable development. In other fields such as medicine and electronic device packaging, they also offer innovative solutions with their unique properties.

However, despite their many advantages, degradable transparent films still face challenges such as high production costs and the need for standardized degradation performance evaluation. Future research and development should focus on addressing these issues and further improving the performance and cost-effectiveness of these films. With continued efforts in technology innovation and the increasing demand for sustainable materials, we can expect degradable transparent films to find even broader applications and make greater contributions to environmental protection and the improvement of our quality of life. It is our hope that through the development and utilization of these films, we can move closer to a more sustainable and environmentally friendly future.

Within 15-20 days after received payment...more