- Home

- >

News

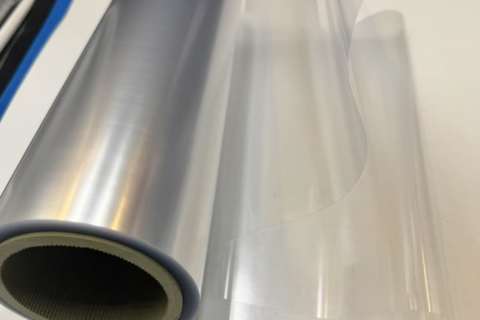

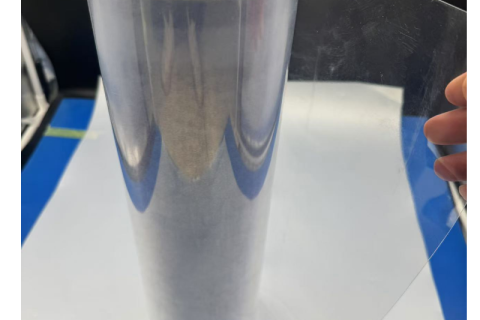

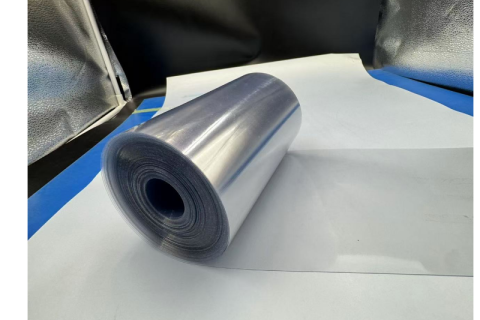

Name: pvc Plastic film roll SizeTk:0.1-0.9mm, h100-1200mm MaterialPVC /Customized Color/printingTransparent/customized PackagingCartons/customized OEM/ODMAccepeted MOQ1000KG UsagePHARMA,Vegetable/Fruit/Meat, biscuits FeatureHigh durability, eco-friendly, compression resistance AdvantageCompetitive price, consistent quality, 24 hours online service

Name:PVC/PVDC Plastic film roll SizeTk:0.1-0.9mm, h100-1200mm MaterialPVC/PVDC/Customized Color/printingTransparent/customized PackagingCartons/customized OEM/ODMAccepeted MOQ1000KG UsagePHARMA,Vegetable/Fruit/Meat, biscuits FeatureHigh durability, eco-friendly, compression resistance AdvantageCompetitive price, consistent quality, 24 hours online service

Material: BOPS ANTI FOG sheet Thickness 0.25mm/customization Size: 100mm/Customization GRADE: Food grade film color: transparent/white/ customization location: china usage :for food tray plant tray

NamePVC/PVDC Plastic film roll SizeTk:0.1-0.9mm, h100-1200mm MaterialPVC/PVDC/Customized Color/printingTransparent/customized PackagingCartons/customized OEM/ODMAccepeted MOQ1000KG UsagePHARMA,Vegetable/Fruit/Meat, biscuits FeatureHigh durability, eco-friendly, compression resistance AdvantageCompetitive price, consistent quality, 24 hours online service

Name: PET Plastic film roll SizeTk:0.1-0.9mm, h100-1200mm MaterialPVC/PVDC/Customized Color/printingTransparent/customized Packaging: Cartons/customized OEM/ODM:Accepeted MOQ1000KG UsagePHARMA,Vegetable/Fruit/Meat, biscuits FeatureHigh durability, eco-friendly, compression resistance Advantage:Competitive price, consistent quality, 24 hours online service

Material: PVC ALU ROLL Thickness 0.25mm-customization Size: 80MM/130MM/Customization GRADE: pharma grade film color: white/ customization location: china Usage: Pharmaceutical, dried food container

Material: PET Printable sheet Thickness 0.012mm/customization Size: 100mm/Customization GRADE: Food grade film color: transparent/white/ customization location: china usage :for food tray plant tray

Material: PVC ROLL Thickness 0.45-0.018mm-customization Size: 80MM/130MM/600/Customization GRADE: pharma grade film color: white/ customization location: china Usage: Pharmaceutical, dried food

Material: PET ROLL Thickness 0.45-0.012mm-customization Size: 80MM/130MM/Customization GRADE: FOOD grade film color: white/ customization location: china Usage: Pharmaceutical, food, Fruit, vegetable

ITEM:TL-PVC-0047 Thickness:0.008-2MM Width:100-1350MM color:white blue red orange black customization Roll core:3-7” feature:Water proof Usage:Color sheet, deco film,cover film capability:5000TON/MONTH Sample:Free less than 10KG

1. Advertising and Signage Printable transparent PVC film is widely used in the advertising and signage industry. Its transparency allows for creative designs that can be applied to windows, glass doors, and other transparent surfaces. Whether it's for promoting a brand, announcing an event, or providing directional signage, PVC film offers a sleek and eye-catching solution. The film can be printed with vibrant colors and high-resolution graphics, ensuring maximum visibility and impact. For example, in retail stores, printable PVC film is used to create window displays that attract customers and showcase products. The transparency of the film allows passersby to see inside the store while still being able to view the promotional messages printed on the film. In addition, PVC film can be used for outdoor signage, such as billboards and banners, as it is weather-resistant and can withstand exposure to sunlight, rain, and wind.