- Home

- >

News

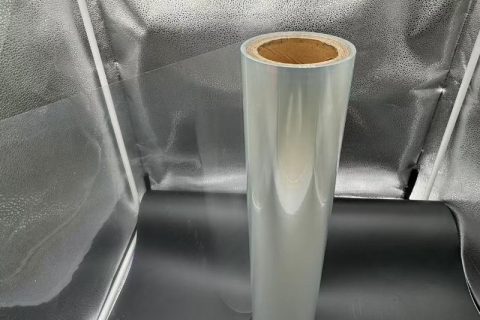

Name, bopp Plastic film roll SizeTk:0.1-0.9mm, h100-1200mm Material: bopp /Customized Color/printingTransparent/customized PackagingCartons/customized OEM/ODMAccepeted MOQ1000KG UsagePHARMA,Vegetable/Fruit/Meat, biscuits FeatureHigh durability, eco-friendly, compression resistance AdvantageCompetitive price, consistent quality, 24 hours online service

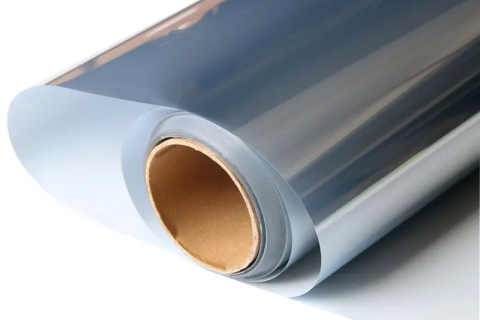

NamePET FILM Plastic film roll SizeTk:0.01-0.9mm, h100-1200mm MaterialPVC/PVDC/Customized Color/printingTransparent/customized PackagingCartons/customized OEM/ODMAccepeted MOQ1000KG UsagePHARMA,Vegetable/Fruit/Meat, biscuits FeatureHigh durability, eco-friendly, compression resistance AdvantageCompetitive price, consistent quality, 24 hours online service

Name:cpp/bopet composite Plastic film roll SizeTk:0.02-0.2mm, h100-1200mm MaterialPET/PP/Customized Color/printingTransparent/customized PackagingCartons/customized OEM/ODMAccepeted MOQ1000KG UsageVegetable/Fruit/Meat/snack FeatureHigh durability, eco-friendly, compression resistance AdvantageCompetitive price, consistent quality, 24 hours online service

Name: bopet Plastic film roll SizeTk:0.1-0.9mm, h100-1200mm Material: bopet/Customized Color/printingTransparent/customized PackagingCartons/customized OEM/ODMAccepeted MOQ1000KG UsagePHARMA,Vegetable/Fruit/Meat, biscuits FeatureHigh durability, eco-friendly, compression resistance AdvantageCompetitive price, consistent quality, 24 hours online service

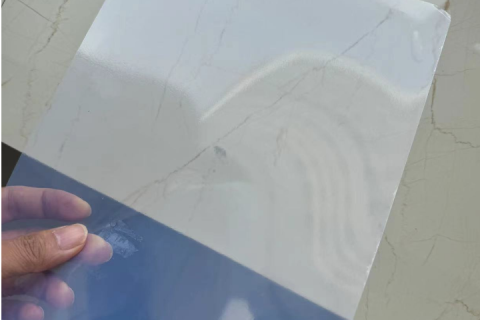

Material: BOPET Printable sheet Thickness 0.012mm/customization Size: 100mm/Customization GRADE: Food grade film color: transparent/white/ customization location: china usage :for food tray plant tray

Title: PP Film Revolutionizes Printable Materials Market Date: August 15, 2023 Location: New York City, NY Key Figures: John Carter, CEO of PrintTech Solutions, and Dr. Emily Roberts, Lead Researcher, Advanced Polymers Lab Event Overview: Although PP film has been a recent spotlight in printing, diverse applications make it an ideal material for various uses. On August 15, 2024, the company leading developments in printable materials, PrintTech Solutions, held a press conference in New York City to introduce their most current innovations in PP film technology. Background: This film is also in great demand in the printing area because of its unique features like flexibility, durability, and lower costs. Unlike other printing material, traditional printing PP film will provide a non-porous, smooth surface for high-quality printing of vivid colors and sharp details. With such properties, it finds greater application in labels, packages, banners, and several other printed material types. According to John Carter, chief executive of PrintTech Solutions, demand for sustainable, high-performance printing materials is growing fast. "As companies look at reducing their environmental footprint while maintaining the highest level of quality, PP film becomes the material of choice in a broadening range of applications," he added. Development Process: According to Dr. Emily Roberts, lead researcher of the Advanced Polymers Laboratory, several breakthroughs in science have made the development of advanced PP films possible. She further elaborates on the research orientation: "In our team, we had focused on the improvement of the printability of PP film by adjusting its surface properties and improving its compatibility with flexographic, digital, and screen printing technologies.". The team has also worked on enhancing its resistance to fading so that the film retains the brilliance of the printed matter, even when exposed to blinding sunlight for a longer period and harsh environmental conditions. Result and Impact: The result of these innovations is a new line of PP films that are more durable, flexible, and increasingly environment-friendly. PP films developed by PrintTech Solutions are fully recyclable and produced with a lower carbon footprint compared to traditional materials, in line with the growing consumer demand for sustainable products and the industry's move toward eco-friendly practices. These advanced PP films, therefore, within the very short time of their introduction, have brought tremendous change in the printing industry. Some big houses have started using the material for their packaging and promotional material and commented positively about the superior print quality, durability, and sustainability. Moreover, it is cost-effective and also turned out to be very impressive for a business venture by cutting down costs without affecting the quality. Conclusion: The importance of PP film in the future will only continue to rise with the further expansion of the market in printable materials. Companies at the forefront of such developments are those like PrintTech Solutions, and leading educational research institutions like Advanced Polymers Lab; PP film will soon become a benchmark within the industry for quality and sustainability in printing. Their success is just another indication of the growing requirement for materials that can answer both performance and environmental demands, setting a new benchmark for the future of printable materials.

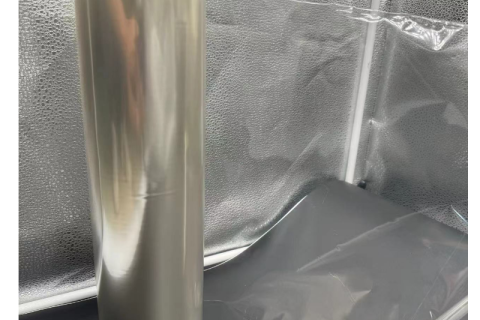

An application of the BPET conductive material boosts the electronics industry. August 2024, Shanghai, Global Electronics Manufacturing Exhibition; Zhang Qiang: technical director of a leading electronics materials R&D company. In August 2024, at the Global Electronics Manufacturing Exhibition held in Shanghai, a new type of conductive material took center stage. The Technical Director, Zhang Qiang, of one of the key Electronics Materials R&D enterprises, has brought along with him a team to introduce very latest BPET (Biaxially Oriented Polyethylene Terephthalate) conductive material. This launch marks the large step forward applying static protection and conductive materials within the electronics industry. Background: Help Needed to Meet Increased Demand for Static Protection With their ever-growing sophistication and complication, electronic products are also requiring more dependable static protection and conductive materials. Having noticed this emerging market demand, Zhang Qiang and his group embarked on a multi-year development program in search of creating a high-performance material to satisfy the demand. "We all noticed that all kinds of conductive materials available in the market had a number of problems, such as low transparency and unstable conductivity, which limited their usage in high-end electronic devices," Zhang Qiang explained during the launch. "It is this that moved us to develop a material that links high transparency, brightness, and stable conductive performance to serve the industry much better." Process: Overcoming Technical Challenges and Enhancing Performance The BPET material is produced with the help of imported production lines to ensure high transparency, brightness, and crystal-free surfaces with excellent flatness. Food grade slip agents were added by the team into the material to give it excellent surface smoothness, good processability, and well-preserved conductive properties. BPET sheets come in various specifications, thereby allowing for high production capacity at superior quality and cost-effectiveness. This is an environment-friendly and non-toxic material that meets QS food safety certification and passes the European Union's SGS environmental certification, hence suitable for industries with strict compliance criteria to safety and the environment. The following are several conductive grades for the materials: - Permanent Conductive Sheet: $10^10$ ohms - Permanent Antistatic Sheet: 10^10 ohms - Permanent Semi-Conductive Sheet: 10^6-10^9 ohms These variations show steady and smooth conductive performance, which ensures the stability and reliability of products for various applications. Besides, BPET can be processed into flat sheets, slit, and laminated; while PET-G and GAG grades are especially suitable for producing high-end electronic products. Result: Good Market Response and Wide Industrial Application In the exhibition, BPET conductive material was very fast.

Anti-Static Protection Static electricity can cause damage to electronic components and interfere with the functioning of sensitive equipment. Transparent PET rigid film with anti-static properties is designed to dissipate static charge and prevent electrostatic discharge.

Name: BOPET Plastic film roll SizeTk:0.1-0.9mm, h100-1200mm MaterialBOPET/Customized Color/printingTransparent/customized PackagingCartons/customized OEM/ODMAccepeted MOQ1000KG UsagePHARMA,Vegetable/Fruit/Meat, biscuits FeatureHigh durability, eco-friendly, compression resistance AdvantageCompetitive price, consistent quality, 24 hours online service