- Home

- >

News

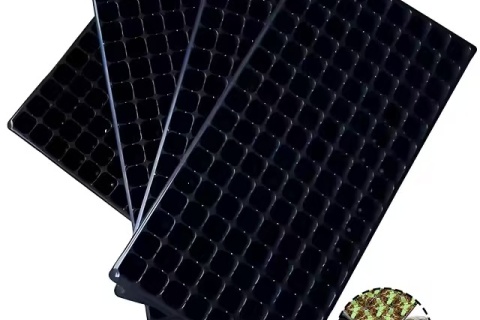

Name: PS Planting tray Plastic film roll SizeTk:0.1-0.9mm, h100-1200mm Material: ps /Customized Color/printingTransparent/customized PackagingCartons/customized OEM/ODMAccepeted MOQ1000KG UsagePHARMA,Vegetable/Fruit/Meat, biscuits FeatureHigh durability, eco-friendly, compression resistance AdvantageCompetitive price, consistent quality, 24 hours online service

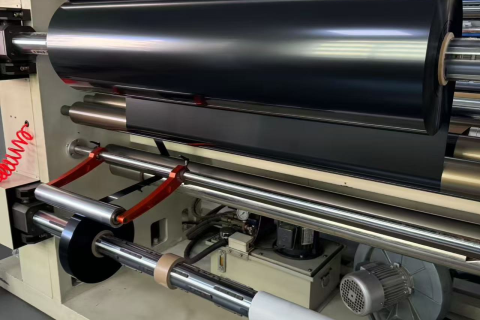

Name: PS Plastic film roll SizeTk:0.1-0.9mm, h100-1200mm Material: PS/Customized Color/printingTransparent/customized PackagingCartons/customized OEM/ODMAccepeted MOQ1000KG UsagePHARMA,Vegetable/Fruit/Meat, biscuits FeatureHigh durability, eco-friendly, compression resistance AdvantageCompetitive price, consistent quality, 24 hours online service

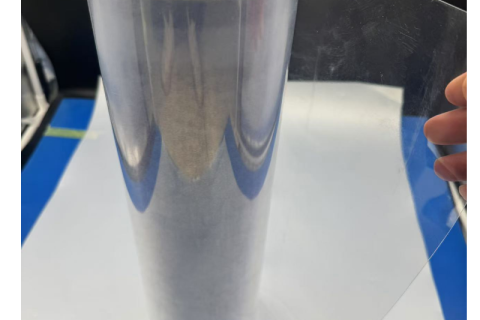

Material: BOPS ANTI FOG sheet Thickness 0.25mm/customization Size: 100mm/Customization GRADE: Food grade film color: transparent/white/ customization location: china usage :for food tray plant tray

Material: BOPS thermoforming sheet Thickness 0.25mm/customization Size: 100mm/Customization GRADE: Food grade film color: transparent/white/ customization location: china usage :for food tray, BOPS film, blister packaging, food safety, cosmetic protection, gift presentation

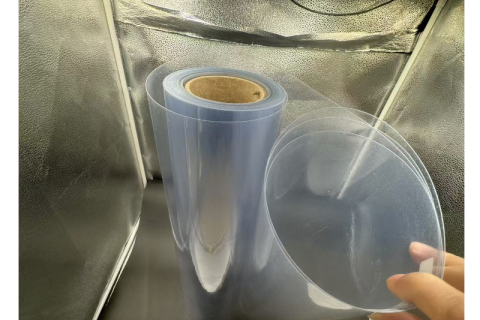

Material: pof shrink film roll Thickness 0.012mm/customization Size: 100/Customization GRADE: Food grade film color: white/fog/matt/ clear customization location: china usage: for food protection, food heat-sealing box,lamination

Name: PS Plastic film roll SizeTk:0.1-0.9mm, h100-1200mm MaterialPS/Customized Color/printingTransparent/customized PackagingCartons/customized OEM/ODMAccepeted MOQ1000KG UsagePHARMA,Vegetable/Fruit/Meat, biscuits FeatureHigh durability, eco-friendly, compression resistance AdvantageCompetitive price, consistent quality, 24 hours online service

Material: ps Thermal formed FILM ROLL Thickness 0.20mm/customization Size: 300mm/Customization GRADE: TOP grade film

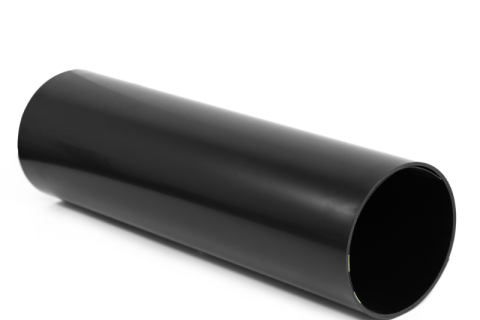

Material: PS Thermal formed roll Thickness 0.25-0.9mm/customization Size: 300mm/Customization GRADE: Food grade film color: black/white/ customization location: china usage :for food tray , food container,planting tray

Material: PC sheet Thickness 0.18mm/customization Size: 100mm/Customization GRADE: Food grade film color: white/ customization location: china usage:for food tray plant tray

Material: HIPS ROLL Thickness 0.015mm-customization Size: 100mm-Customization Usage : blister plant tray, food tray AUTO parts color: black /white/ customization location: china

MATERIAL :HIPS FILM THICKNESS:0.025-0.8MM /CUSTOMIZATION WIDTH:100-1350MM/CUSTOMIZATION USAGE: THERMOFORMING BLISTER food plate,HIGHT impact part,elctronic part COLOR: transparent/ CUSTOMIZATION